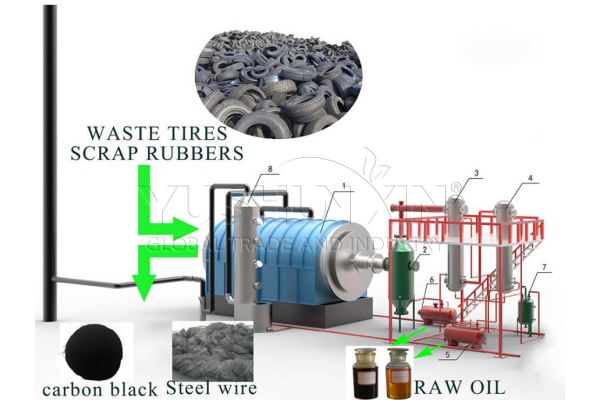

Waste tire pyrolysis plant efficiently converts waste tires into valuable products such as pyrolysis oil, karbon hitam, steel wire, and combustible gas through the pyrolysis process. This advanced recycling technology not only addresses the growing problem of tyre pollution but also creates a highly profitable business opportunity. Lebih-lebih lagi, with increasing global demand for eco-friendly solutions, YUSHUNXIN waste tyre pyrolysis equipment has become an ideal choice for sustainable tyre recycling. Let’s explore more details about this powerful waste tyre recycling system.

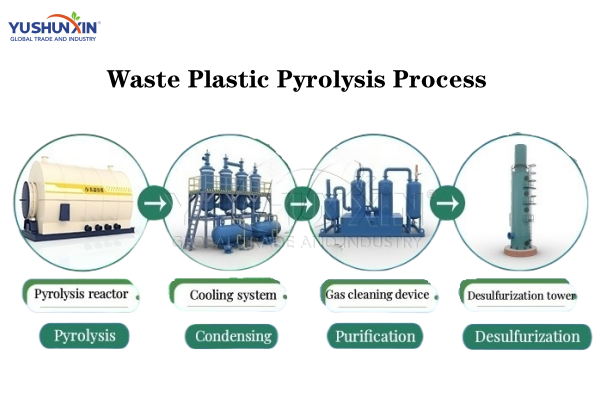

Apa proses kerja pabrik pirolisis ban limbah?

Memuat ban limbah ke dalam mesin pirolisis ban

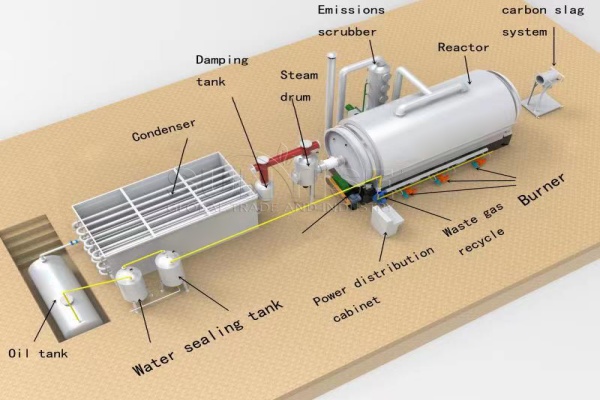

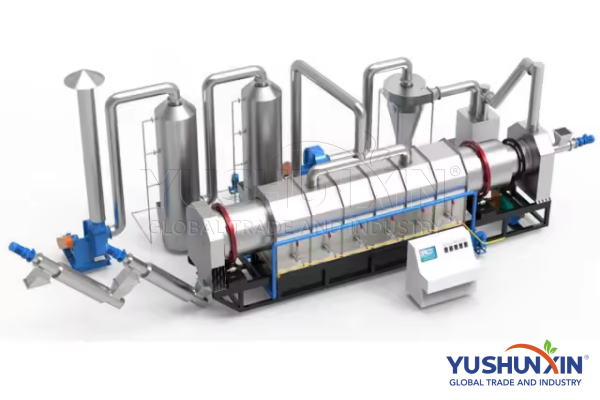

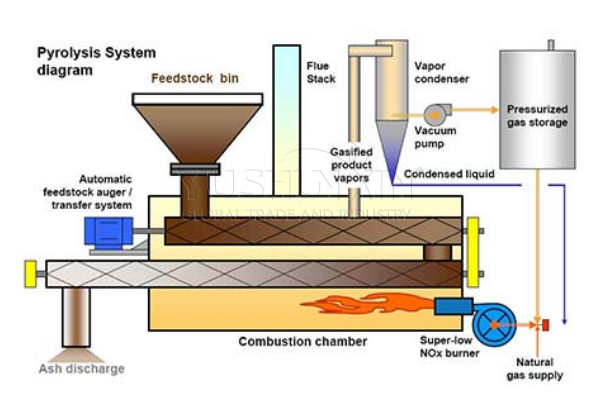

Start by feeding waste tyres into the reactor of the tyre pyrolysis machine through an automatic feeder. Make sure to load only two-thirds of the reactor’s capacity to ensure smooth and efficient rotation during processing. Once the tyres are in, securely close the feeding door to begin the waste tyre to oil conversion process.

Panaskan reaktor dan mulai pemisahan minyak minyak

Heat the reactor using available fuels such as coal, wood, natural gas, or pyrolysis oil from the previous cycle. As the temperature reaches 100°C, oil and gas begin to form. To achieve the highest oil yield, maintain the reactor temperature between 250°C and 280°C. The system separates heavy oil gas in the manifold and channels it into a heavy oil tank after liquefaction. Sementara itu, lighter oil vapors pass through the pyrolysis oil condenser, turn into liquid, and are stored. Non-condensable gases are filtered and recycled back to the furnace for heat generation, improving fuel efficiency.

Mendinginkan reaktor dan memulihkan karbon hitam

After completing the oil production, allow the reactor to cool naturally. When the temperature drops by 40°C, the machine will automatically discharge carbon black into a collection system. If processing whole tyres, wait until the temperature falls below 50°C and then use a mechanical hook to extract the steel wires. This step completes the carbon black recovery process.

Reset untuk siklus pirolisis berikutnya

Before starting the next batch, confirm that all materials have been removed, the reactor has cooled sufficiently, and all safety checks are complete. Persiapan ini sangat penting untuk mempertahankan kinerja jangka panjang dari pabrik pirolisis ban dan untuk memastikan ban limbah yang konsisten ke konversi minyak.

Apa penggunaan produk akhir pabrik pirolisis ban limbah?

Pabrik pirolisis ban limbah telah menjadi yang menguntungkan dan ramah lingkungan Solusi untuk daur ulang ban. Proses ini tidak hanya mengurangi polusi lingkungan tetapi juga menghasilkan banyak produk akhir yang berharga yang dapat diterapkan secara luas di seluruh industri. Berikut adalah rincian dari empat produk utama yang dihasilkan selama proses pirolisis dan aplikasi pasar masing -masing:

Proses pirolisis mengekstraksi minyak pirolisis, yang berisi senyawa yang berguna seperti benzena, toluena, xylene, styrene, dimer kolam, trimethylbenzene, dan tetramethylbenzene. These substances are commonly used as chemical raw materials in various industries.

Lebih-lebih lagi, this oil serves as a substitute for diesel in steel plants, cement factories, boiler systems, and heavy oil generators. With further distillation, pyrolysis oil can be refined into diesel fuel, making it a high-demand energy product in both industrial and transportation sectors.

The process also produces carbon black, which is primarily used as a reinforcing filler in low-grade rubber manufacturing, including tire production and rubber soles. Selain itu, carbon black acts as a pigment for inks and paints.

In its raw form, it can be directly used as solid fuel. Namun, with further milling and refining, it can be upgraded into activated carbon, opening up opportunities in filtration, purification, and chemical adsorption markets, where demand continues to grow.

Ban limbah mengandung kawat baja pegas tertanam, yang tetap utuh selama pirolisis karena suhu rendah, lingkungan bebas oksigen. Ini memastikan bahwa sifat mekanik baja dipertahankan.

Setelah pemisahan, Baja berkualitas tinggi ini dapat dijual kembali ke industri pemrosesan logam atau pemulihan, Menawarkan pengembalian yang menguntungkan dan mendukung ekonomi melingkar di bidang metalurgi.

Selama pirolisis, Sejumlah besar gas yang mudah terbakar dihasilkan. Daripada melepaskannya, Pabrik mendaur ulang gas ini sebagai sumber bahan bakar internal untuk memanaskan reaktor itu sendiri. Sistem loop tertutup ini mengurangi biaya operasional dan meminimalkan emisi berbahaya, Meningkatkan efisiensi energi dan kinerja lingkungan.

Solusi Harga Tanaman Pirolisis Ban

Looking for an affordable and efficient waste tire pyrolysis plant? Whether you’re a small recycler or a large-scale investor, choosing the right capacity and price range is crucial for ROI and long-term stability.

| Kapasitas (Tons/Day) | Type | Estimated Price (USD) | Recommended For |

| 1-3 TPD | Batch | $30,000 - - $60,000 | Small startups |

| 5-10 TPD | Semi-Continuous | $65,000 - - $120,000 | Medium-sized plants, flexible ops |

| 12-20+ TPD | Fully Continuous Line | $130,000 - - $300,000+ | Industrial-grade, large-scale |

Tip: Beware of overly cheap offers lacking CE/ISO certifications or proper emission control systems.

In order to further help you know the profit of waste tire pyrolysis plant, we can provide you with profit analysis of 12T/D waste tyre pyrolysis plant.

| Running cost / day | |

| Ban buang | 12T*73USD/T=876USD |

| Heating fuel (Just choose one from the options) |

1)Coal: 0.4T*58USD/T=23USD 2)Fuel oil: 0.4T*364USD/T=146USD 3)Diesel: 0.3T*582USD/T=175USD 4)Natural gas: 150M3*0.33USD/M3=4.9USD |

| Power consumption | 15Kw/h |

| Water consumption | Water is for circulating use, no consumption |

| Required workers | 3 workers per shift * 22USD = 65USD |

| Income / Day | |

| Fuel oil | 4.5T*364USD/T=1637USD |

| Carbon black | 1)selling directly, 3T*73USD/T=218USD 2)grinding, 3T*291USD/T=873USD |

| Steel wire | 1.5T*116USD/T=175USD |

| Daily profit (Use fuel oil for heating and sell carbon black directly) |

1302USD/Day |

What more manufacturers want to know about waste tire pyrolysis plant?

About waste tire pyrolysis, you may have many other things want to know. There are some items commonly asked from our customers- waste tire recyclers for your reference. If you need more information of tire pyrolysis and machines, welcome to inquiry us immediately.

As a waste tire pyrolysis plant manufacturer with 10 years of rich experience, Yushunxin tidak hanya dapat menyediakan pabrik pirolisis ban limbah berkualitas tinggi, tetapi juga dapat mengkonfigurasi pabrik pirolisis ban limbah sesuai dengan situasi spesifik Anda untuk membantu Anda mengatur jadwal proyek. Dan jika Anda membutuhkan limbah ban hancur dan memisahkan, Kami juga dapat menawarkan untuk Anda. Hubungi kami sekarang untuk penawaran gratis di pabrik pirolisis ban limbah.

Hubungi kami