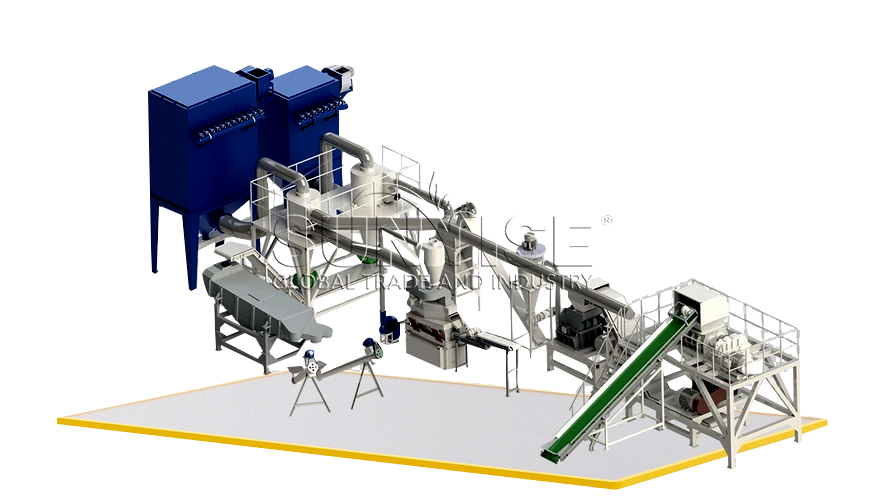

A circuit board scrap recycling plant is a specialized facility designed to recover valuable materials from discarded printed circuit boards (PCBs). The recycling process involves several stages, each requiring specific types of equipment. The main equipment used in such a facility is crucial for efficiently extracting valuable metals, reducing environmental impact, and ensuring worker safety. Below, we delve into the key equipment used in a circuit board scrap recycling plant.

Pre-Processing Equipment

Shredders are the initial equipment used to reduce the size of circuit boards. High-capacity, low-speed industrial shredders are designed to break down PCBs into smaller, manageable pieces. This size reduction is essential for subsequent separation processes.

Features: Robust construction, adjustable shredding size, and overload protection.

Benefits: Enhances the efficiency of downstream processes and ensures consistent material feed.

Separation Equipment

Magnetic separators are used to extract ferrous metals (such as iron and steel) from the shredded and granulated material. These separators use powerful magnets to pull ferrous metals away from the non-ferrous fraction.

Features: Drum or belt magnets, adjustable magnetic strength, and continuous operation.

Benefits: Efficient removal of ferrous metals, protecting downstream equipment from damage.

Air classifiers use airflow to separate materials based on their density and size. Lighter, non-metallic materials are carried away by the air stream, while heavier metallic particles fall into a separate collection area.

Features: Adjustable airflow, multiple separation stages, and integrated dust collection systems.

Benefits: Efficient separation of fine particles, reducing the load on subsequent processing equipment.

Electrostatic separators use electrical charges to separate conductive materials (such as metals) from non-conductive materials (such as plastics). This technology is particularly effective for fine particle separation.

Features: High-voltage electrostatic fields, adjustable separation parameters, and high throughput capacity.

Benefits: Precise separation of mixed materials, enhancing the purity of recovered metals.

Auxiliary Equipment

Dust and Fume Extraction Systems

Given the potentially hazardous nature of PCB recycling, dust and fume extraction systems are essential for maintaining air quality and protecting worker health.

Features: High-efficiency particulate air (HEPA) filters, adjustable airflow rates, and automated monitoring systems.

Benefits: Reduces airborne contaminants, ensuring compliance with environmental and safety regulations.

Automated Control Systems

Automated control systems monitor and manage the entire recycling process, ensuring optimal operation and efficiency.

Features: Real-time data acquisition, process control algorithms, and remote monitoring capabilities.

Benefits: Increases process efficiency, reduces downtime, and ensures consistent product quality.

Contact Us