Price reference for lithium battery recycling machines

| Li-ion Recycling Machines | Price Range (USD) |

|---|---|

| Shredder | $5,000 – $30,000 |

| Crusher | $8,000 – $30,000 |

| Magnetic Separator | $3,000 – $15,000 |

| Rotary Vibrating Screen | $4,000 – $18,000 |

| Milling Machine | $6,000 – $25,000 |

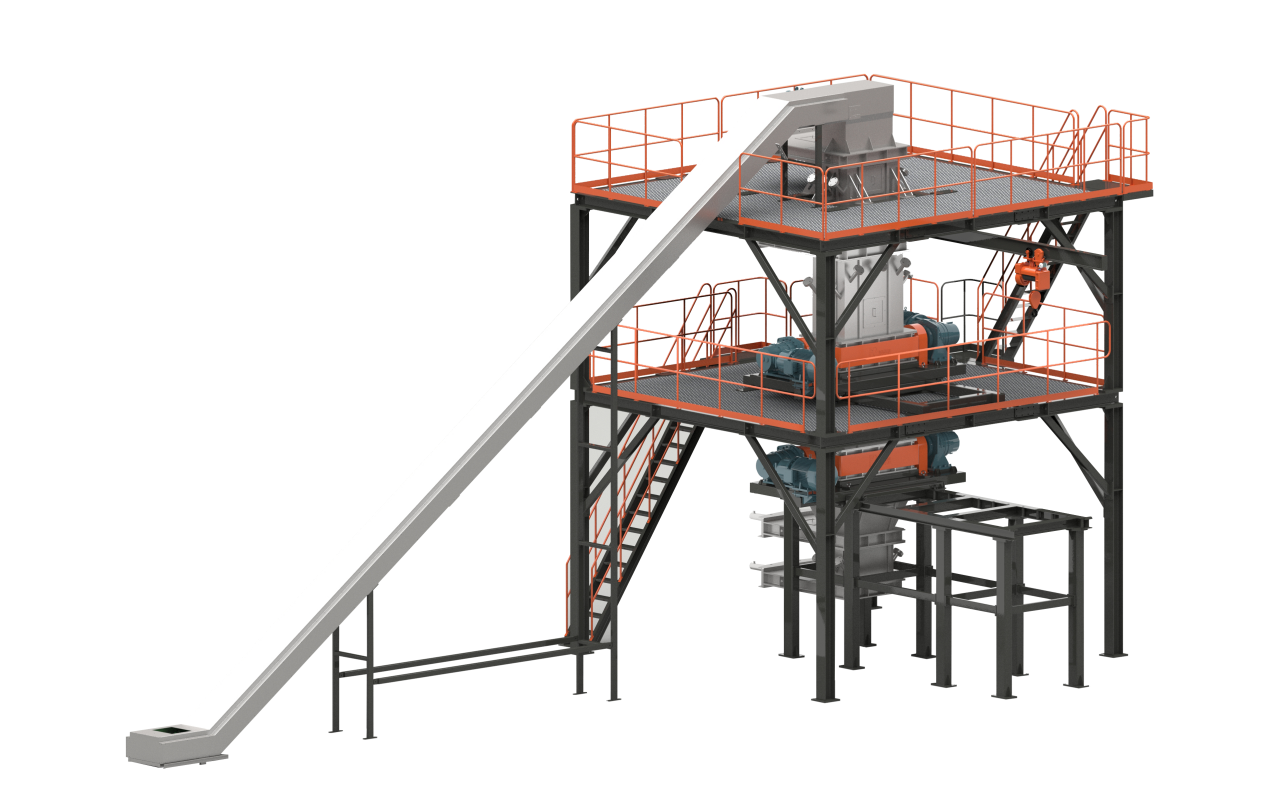

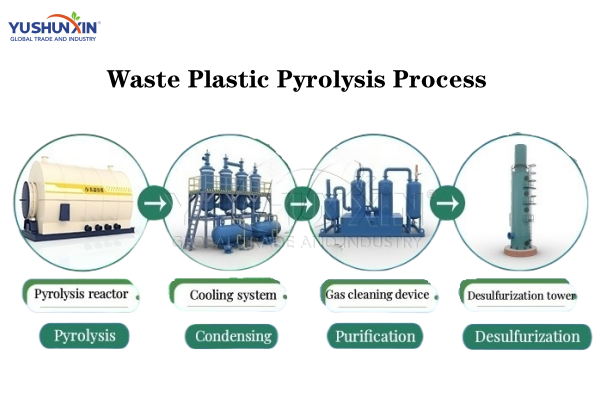

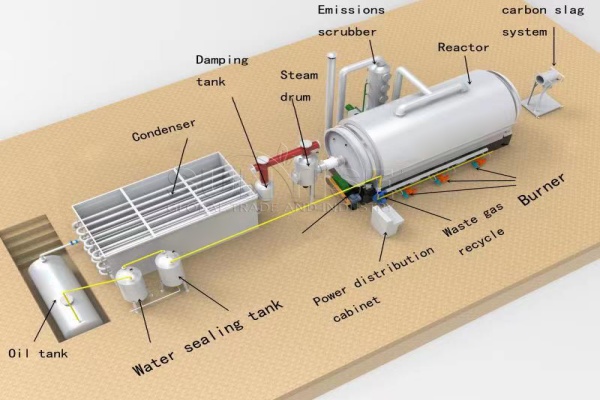

Top 3 solutions for lithium-ion batteries recycling

Purchase and maintenance costs of Lithium ion Batteries Recycling Equipment

Pricing of End Products from Lithium Battery Recycling Line

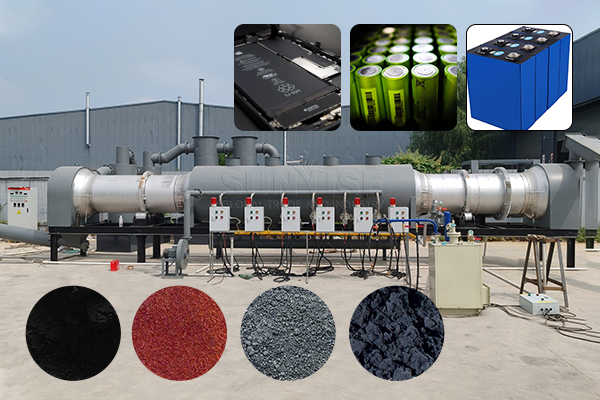

The resulting materials are separated into two main product: battery materials (black mass) and metal such as mixed copper/aluminum.

Metals

Battery materials (black mass)

Black mass is a mixture of various substances obtained after the initial treatment of lithium batteries. It contains valuable metals and other materials. Although the price of black mass is not as high as that of pure metals, it is also an important source of income for recycling enterprises. The price of pure black mass is usually between $2,000 and $5,000 per ton, depending on its quality.

Plastic and Other Materials

Plastic, cell case and other materials in lithium batteries can also be recycled and reused. The price of recycled plastic is about $1,000 per ton. Although the price is not high, recycling these materials can reduce environmental pollution and resource waste.

6 Key Factors Affecting Lithium Battery Recycling Line Pricing

Are you still evaluating li-ion batteries recycling machines costs? Understanding price drivers helps you make informed decisions and avoid budget surprises. Below, we break down the critical factors impacting recycling line pricing and reveal how to optimize ROI with smart investments.

Production Capacity: Matching Throughput to Your Recycling Business Goals

- 1

Entry-Level Lines (300-500 kg/hour): Ideal for startups or low-volume processors. Compact shredders and crushers handle basic EV/pouch cell recycling. Starting at $50,000.

- 2

Industrial-Grade Systems (1,000+ kg/hour): High-capacity shredders, automated sorting, and separation modules for large-scale operations. $500,000+ with 30% higher material recovery rates.

- 3

Pro Tip: Overcapacity = wasted capital. Our engineers analyze your feedstock volume to design cost-effective, future-proof systems.

Recycling Technology: Balancing Automation & ROI

| Feature | Basic Model | Advanced Model |

|---|---|---|

| Recovery Rate | 75 – 80% | 92 – 95% |

| Safety | Manual hazard control | Explosion – proof chambers |

| Labor Costs | 5 – 8 operators | Fully automated (2 – 3 staff) |

| ROI Timeline | 18 – 24 months | 12 – 15 months |

Case Study: A client upgraded their first new PPL for li-ion battery recycling to advanced recycling system, achieving $220k/year savings in labor and material loss.

Manufacturer Reputation: Why Trust Matters

- 1

Certified Brands (Exclusive Partner): ISO 9001/CE-certified machinery with 10-year lifespan and <1% downtime.

- 2

Budget Alternatives: 60% higher maintenance costs reported by users of uncertified systems.

- 3

YSX Advantage: 24/7 multilingual tech support + lifetime spare parts guarantee.

Hidden Costs Exposed: Logistics & Compliance

Don’t let these blindside your budget: Shipping, Taxes: 5-22% import duties (varies by country), Certifications: CE/WEEE compliance.

–Solution: Our DDP Service covers:

Doorstep delivery (0% logistics stress)

Full customs clearance

Local compliance certification

After-Sales Support: The Hidden Key to Long-Term Profitability

What YSX Top-Tier After-Sales Service Looks Like?

- Zero-Downtime Guarantee:

24/7 remote troubleshooting

On-site technician dispatch globally

98% first-visit fix rate for mechanical/software issues - Cost Predictability:

1-Year Comprehensive Warranty: Covers wear-and-tear parts like shredder blades ($12k replacement value) - Dedicated Account Managers: Fluent in 12 languages, handling everything from warranty claims to ESG reporting.

Future-Proofing: Modular Upgrades That Pay Off

Why 370+ Clients Choose Us?

- 37% faster ROI vs. industry average

- 100% customs clearance success

- 1.2M tons e-waste recycled using our recycling machines

Ready for a Quotation for Spent li-ion Batteries Recycling Machines?

Contact Us