If you work in automotive, electronics or energy storage, you may have noticed this. As people become more aware of environmental protection and the scarcity of raw materials used in battery production, there is a strong demand for recycled battery materials. This means there is an urgent need for efficient battery recycling solutions. The following business plan is for 300 kg/h lithium-ion battery recycling. Maybe it will give you some new ideas for business.

Why is lithium ion battery recycling a promising project?

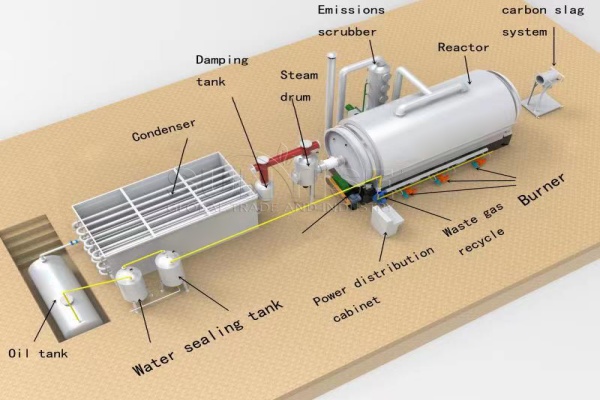

Essential Equipment

Technological Process

The entire production line of lithium battery recovery equipment is fed by conveyor materials into the crusher of the first process for coarse crushing. The coarse crushed materials are fed by conveyor to the secondary crusher for secondary crushing. The crushed materials from the secondary crusher enter the conveyor and magnetic separation equipment to separate the iron in the materials. After the conveyor and magnetic separator removing the iron, it enters the three crusher for fine crushing, crushing the material to powder. Materials in powder state enter the cyclone separator through the negative pressure system for air filtration, and then fall onto the air flow separator through the fan. The air flow separator separates materials of different densities to obtain metal separation, while the negative pressure system brings all non-metals into the pulse dust collector for concentration. The negative pressure system continues to send the filtered tail gas to the tail gas treatment equipment for air purification, ensuring that it meets national emission standards before discharging it at high altitude.

Financial considerations for 300 kg/h lithium ion battery recycling

When planning your lithium-ion battery recycling business, it is essential to consider the financial aspects, including the initial investment, operational costs, and potential revenue. At SUNRISE, we offer customized solutions to fit various production capacities.

SUNRISE: Your Trusted Partner

Contact Us