Elke jaar, oor 1.5 miljard skrootbande belas ons planeet as industriële “Swart besoedeling” – Met die VSA weggooi 300 miljoen eenhede en EU -herwinning 4 miljoen metrieke ton.

Nietemin, Hierdie groeiende omgewingskrisis verberg 'n goue sakegeleentheid: Moderne produksielyne vir die herwinning van bande omskep nou weggegooide rubber in hoë waarde kommoditeite soos rubberpoeier, Staal drade, en pirolise olie. Soos die wêreldwye vraag na volhoubare vervaardiging styg, Innoverende fabrieke gebruik die nuutste bandeherwinningsapparatuur om ekologiese uitdagings in winsgewende ondernemings te omskep.

Vandag sal ons ondersoek hoe outomatiese bande -herwinningslyne werk, hulle ROI potensieël, En waarom hulle stelsels word vir vooruitdenkende afvalbestuurondernemings.

Watter grondstowwe is geskik vir herwinningslyne vir afvalbande?

The waste tire recycling line can efficiently process various types of waste tires (rubber materials). Then turning them into valuable or reusable products. Below are some suitable raw materials that can be processed through waste tire recycling line.

Wat is die herwinningslyn van die afvalband?

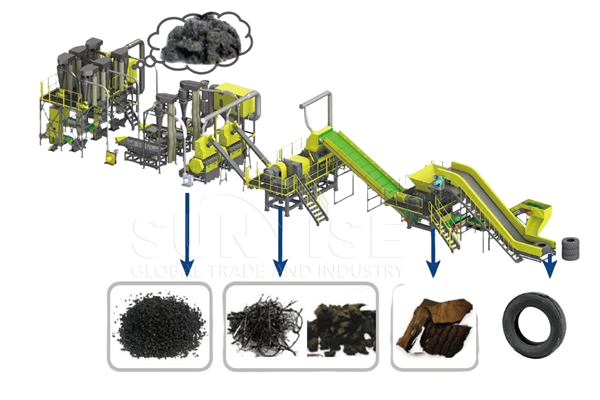

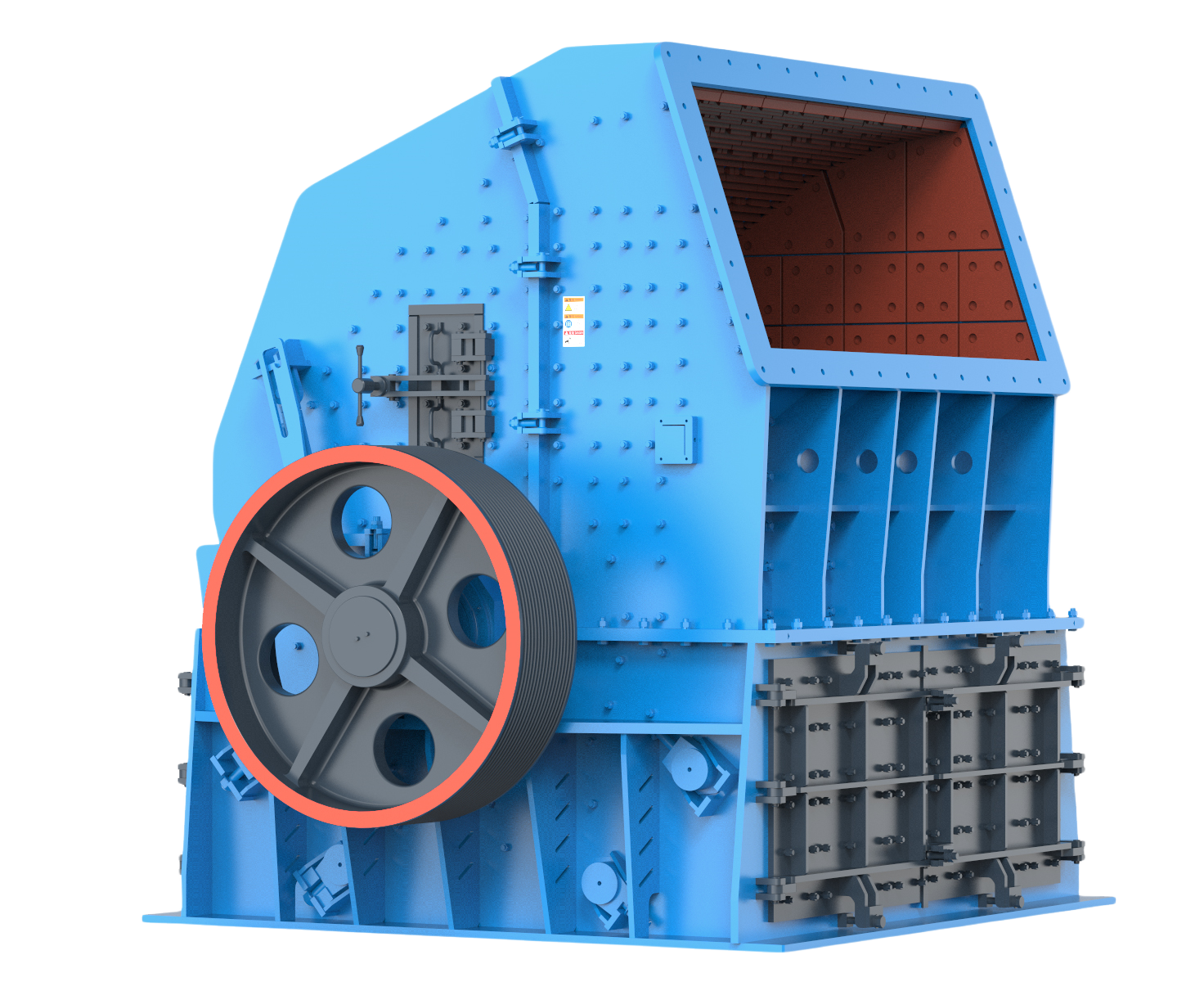

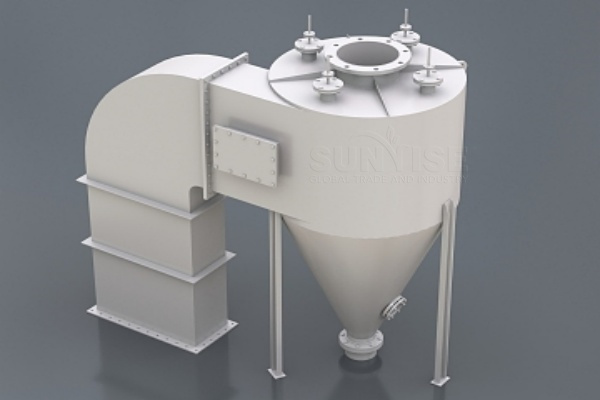

Our waste tire recycling line includes a comprehensive array of specialized machines. This modular setup ensures that each stage of the recycling process is efficient, environmentally friendly, and produces high-quality output materials suitable for a range of applications.

Wat is die proses van die herwinningslyn van afvalbande?

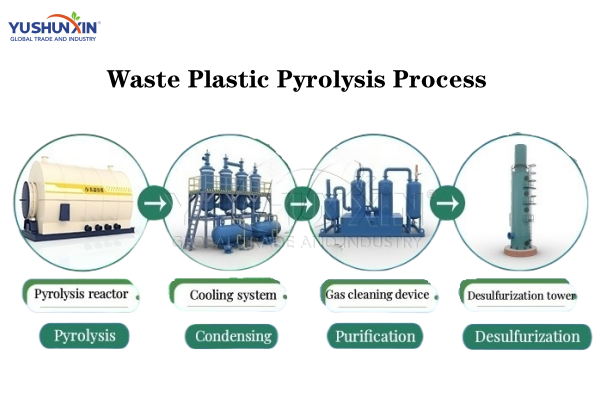

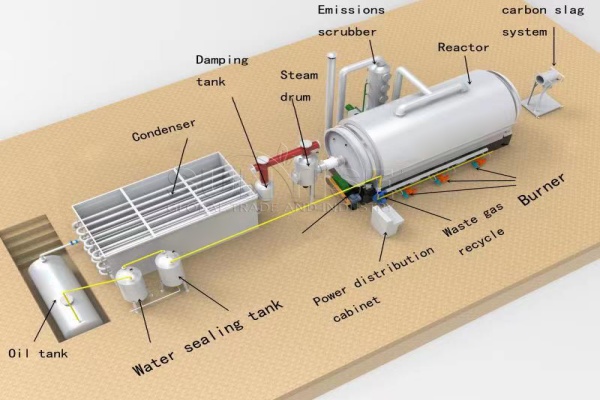

The YSX waste tire pyrolysis recycling system represents an innovative industrial solution that leverages pyrolysis technology to transform end-of-life tires into commercially viable resources. This advanced recycling infrastructure not only provides an effective approach to managing waste tire accumulation but also enables the production of valuable by-products with significant economic potential.

Materiële inset

Waste tires or processed rubber powder are systematically fed into the pyrolysis reactor, serving as the primary feedstock for the conversion process.

Termiese verwerking

The reactor is heated using various fuel sources, including tyre pyrolysis fuel oil, liquefied petroleum gas (LPG), natural gas, coal, or biomass. This heating phase initiates the pyrolysis reaction, prompting the chemical decomposition of tire materials at elevated temperatures.

Neweproduk-skeiding

As the temperature inside the reactor increases, gaseous hydrocarbons are released from the pyrolyzing tires. These vaporous components undergo a condensation process to form pirolise olie—a valuable output—while non-condensable gases undergo desulfurization and dust removal treatments. These treated gases can either be recycled to supply heat for the reactor or safely discharged into the atmosphere.

Reaktorverkoeling en residu -ekstraksie

Once the pyrolysis cycle is completed, the reactor is gradually cooled. Following this cooling phase, die soliede oorskot - hoofsaaklik saamgestel uit koolstof swart—Is verwyder vir verdere verwerking of gebruik.

Emissiebeheer

'N Toegewyde uitlaatgasuiweringstelsel word gebruik om enige oorblywende gasvormige emissies te behandel, om te verseker dat alle ontladings aan streng omgewingsregulasies en standaarde vir luggehalte voldoen.

Hierdie geïntegreerde benadering kombineer doeltreffende materiaalomskakeling met omgewingsverantwoordelikheid, Die vestiging van die YSX -bande -pirolise -herwinningslyn as 'n volhoubare oplossing vir afvalbandebestuur en hulpbronherstel.

Voordele van YSX Waste Tire Recycling Line

Want to know more about tyre recycling? Our team is here to help! We are available 24/7 to provide tyre recycling machines and solutions. Contact us anytime for professional support. Ons is net 'n boodskap weg!

Kontak ons