In the process of e-waste recycling, people use magnetic separator equipments to separate and recover different types of metals, especially ferromagnetic metals. Here are some common types of magnetic separators used in e-waste recycling, maybe you will be interested in it.

When selecting a suitable magnetic separator for e-waste recycling, it is important to consider the nature of the materials, the processing volume, and the separation requirements. These magnetic separation devices can effectively improve the efficiency of e-waste recycling and reduce resource waste.

Magnetic Drum Separator

Permanent Magnetic Drum Separator: Utilizes permanent magnets to separate ferromagnetic metals from e-waste.

Electromagnetic Drum Separator: Imagwiritsa ntchito coil yamagetsi kuti ipange gawo la maginito kuti mulekanitse zida za Ferromagnetic.

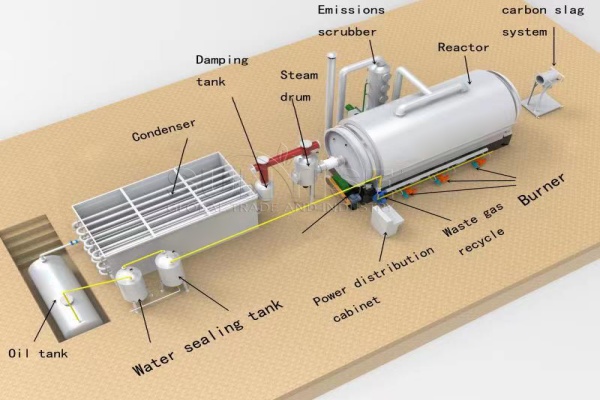

Kutuluka kwa Druman 'Drum Olekanitsidwa Kuchotsa Zidutswa zazikulu ndi zazing'ono za zitsulo zodetsa nkhawa zakunja. Maginito okhazikika amphamvu amathandizira kwambiri magwiridwe antchito abwino kwa ntchito zingapo zomwe kale. Amapereka zaka zovuta - Kuchotsa kwa Termp, kuphatikiza zinthu zazikulu komanso zazikulu kwambiri.

Monga momwe zinthu zimafikira ng'oma, Mphepo yamagetsi imakopa ndipo imagwira tinthu tating'onoting'ono tomwe timayendetsa chipolopolo. Drum limatanthauzira, Imanyamula zinthuzo kudzera pamunda wamagetsi. Chipolopolo chimatulutsa zinthu zomwe sizimagwera momasuka, while the magnetic particles remain firmly held until they are carried out of the magnetic field.

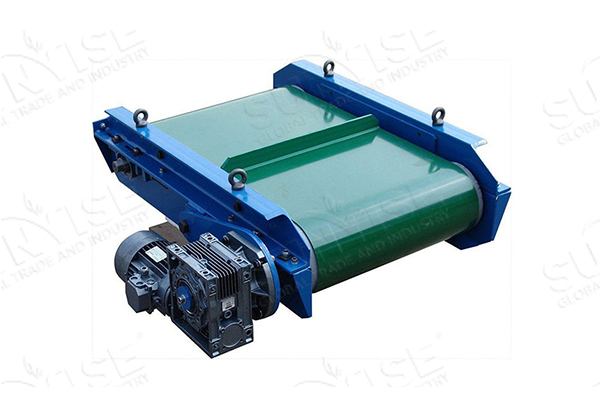

Overband Magnetic Separator

Also known as a suspension magnet, it hangs above conveyor belts and automatically removes ferromagnetic metals from large quantities of non-magnetic materials.

Magnetic Pulley

People install these magnetic pulleys at the discharge end of conveyor belts to attract and separate metal particles, allowing non-metallic materials to be discharged smoothly.

Eddy apakati

This device separate non-ferromagnetic metals (such as aluminum and copper). It generates eddy currents to repel these metals, separating them from other materials.

Dry Magnetic Separator

Olekanitsidwa owuma amatha kusiyanitsa zinthu za Ferromagnenetic ku zosankhidwa. Amakhala ndi mawonekedwe osavuta, Ntchito Yosavuta, ndi kukonza, ndipo ali okhwimitsa mwaluso komanso okhazikika mu magwiridwe antchito, kuwapangitsa kukhala ogwiritsa ntchito bwino kwambiri pabwino.

Amaphatikizapo ng'oma yamagetsi, wodyetsa, ndi lamba wonyamula. Zipangizo zimagawidwa kwambiri pa lamba wonyamula ndi wodyetsa, komanso motsogozedwa ndi maginito, Tizilombo ta Ferromagnenetic zimakopeka, Pomwe osakhala maginito amagwera akupitilizabe kusuntha ndipo atulutsidwa.

Magalimoto a Magnetic ndi Maginito

Ikani magnetic pamtunda wa magnetic pamwamba pa malamba kapena mkati kuti muchotse zodetsa zazikulu. Timakhazikitsa magnetic mipiringidzo mu hopper, Amagwa, ndi mapaipi oti mugwire ntchito zofananira.

Maginito a magraneti

Yopangidwa ndi machubu ophatikizidwa ndi gridi. They are used to remove ferromagnetic contaminants from free-flowing dry products such as grains and powders.

Why Recommend Dry Magnetic Separators over Wet Magnetic Separators in E-Waste Recycling?

- 1

Dry Materials: Utoto, such as discarded circuit boards and old electronics, typically exists in a dry state. Dry magnetic separators are better suited for handling these dry materials without the need for pre-wetting treatment.

- 2

Water Resource Conservation: Dry magnetic separators do not require water, saving a significant amount of water resources and related water treatment costs. Wet magnetic separators use water as a medium, which produces wastewater containing heavy metals and other contaminants, necessitating additional wastewater treatment steps, thereby increasing treatment costs and environmental burdens.

- 3

Simplicity: Dry magnetic separators have a relatively simple structure, making them easier to operate and maintain without the need for complex water treatment systems. Wet magnetic separators involve pumps, pipes, and other components, making the system more complex and harder to maintain.

- 4

Metal Separation Efficiency: Dry magnetic separators are highly efficient in separating ferromagnetic metals (such as iron and nickel), meeting the separation requirements of e-waste recycling well. People mainly use wet magnetic separators to process mineral raw materials with fine particles, and they do not commonly apply them in e-waste recycling.

- 5

People can effectively control the dust produced by dry magnetic separators through the use of enclosed systems and dust removal devices. Wet separators can make equipment and the work environment humid, leading to other safety and hygiene issues.

- 6

People have widely applied dry magnetic separators in the e-waste recycling industry, achieving mature technology and stable equipment performance. In contrast, they mainly use wet magnetic separators in the mining industry, resulting in relatively less applicability and technical accumulation for e-waste recycling.

Lumikizanani nafe