A matsayin sabon abin hawa na samar da wutar lantarki (Na garin nev) kasuwa ta ci gaba da fadada fadakarwa, batun sake dawowar abin hawa ya fito a matsayin wani al'amari mai mahimmanci don ci gaba mai dorewa na masana'antu. Da 2025, Muna tsammanin cewa sake amfani ba kawai zai zama wajibcin kariyar muhalli ba amma kuma yuwuwar tushen albarkatu da damar tattalin arziki. Tare da kara adadin na karshe-rayuwa, Hanyoyin sakawa da suka dace da abubuwan more rayuwa zasu zama mahimmanci don magance motsin motocin da aka watsar.

Kuna iya sake maimaita wadanne ɓangarorin sabbin motocin makamashi?

Abubuwan da aka sake fasalin akan sabon motar lantarki (Na garin nev) saman abin saman

Gilashin taga navs na iya shawo kan kuma sake sake shi. Wannan tsari ya shafi fasa gilashin zuwa kananan guda, Wanne zai iya narke kuma ya zama ya zama sabon samfuran gilashin, Rage bukatar budurwar budurwa.

Bugu da ƙari, Jirgin saman jikin motar, wadanda aka yi amfani da su a cikin masana'antar abin hawa na zamani don hasken rana da dorewa, ana iya murƙushe kuma ana sarrafa su don samar da fa'idodin tattalin arziki. Za'a iya amfani da wuraren da aka sake amfani dasu a masana'antu daban-daban, such as the production of plastic pellets for manufacturing new plastic components or in the construction industry for non-structural applications.

Recyclable materials inside energy electric automobiles

Lithium batteries in new energy battery electric vehicles (BEV) are a significant source of precious metals. These batteries contain elements like lithium, cobalt, nickel, and manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Lithium batteries in new energy battery electric vehicles (BEV) are a significant source of precious metals. These batteries contain elements like lithium, cobalt, nickel, and manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Which machines can recycle valuable materials in new energy EVs

When it comes to recycling the car shells of new energy EVs, heavy-duty shredding machines are essential. These shredders can handle the large and sturdy metal structures. Misali, hydraulic crushers with a powerful motor can exert high pressure to break down the car bodies into smaller pieces. They usually have a large crushing chamber and adjustable jaws to accommodate different sizes of car parts. The power of such crushers can range from 50 kW to 150 Kwat, enabling them to efficiently process the thick metal sheets of the car shells.

For the recycling of window glass, specialized crushers are required. These crushers are often equipped with toughened blades and a vibrating feeder system. The blades are made of high-quality alloy to withstand the hardness of the glass. The vibrating feeder ensures a continuous and even supply of glass pieces to the crushing area. Some advanced glass crushers can achieve a crushing size as small as 1 – 5 mm, which is crucial for further processing and separation of the glass components. The power consumption of these crushers is relatively lower compared to those for car bodies, typically around 10 kW to 30 Kwat.

Circuit boards in new energy EVs contain valuable metals and components. Crushers designed for circuit boards need to be more precise and gentle to avoid damaging the precious materials. They usually employ a combination of mechanical shearing and impact forces. The crushers have fine-toothed rollers and a controlled crushing mechanism to break the circuit boards into small fragments while preserving the integrity of the metals and semiconductors. The power of these crushers is generally in the range of 20 kW to 50 Kwat.

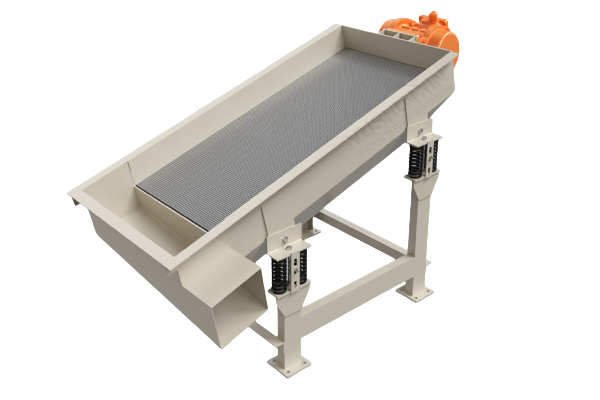

Vibrating screens with different mesh sizes are commonly employed. These screens can separate the crushed materials based on their particle size. Misali, a vibrating screen with a mesh size of 2 – 10 mm can effectively sift out the aluminum particles from the non-metallic debris. The screening efficiency is crucial to ensure the purity of the recovered metal elements. Our screening machines are equipped with intelligent control systems to adjust the vibration frequency and amplitude, optimizing the separation process.

Magnetic vibrating screens are widely used for separating metal elements. These screens utilize the magnetic properties of metals to attract and separate them from the non-metallic materials. They consist of a vibrating deck with built-in magnets and a variable-frequency drive system. Za'a iya daidaita ƙarfin gyaran magnetic bisa ga nau'in da girman barbashi na ƙarfe da za a iya dawo dasu. Misali, don ƙananan ƙarfe gutsuttsukan, wani yanki na gyaran maganadi 2000 – 3000 Gautus ya isa, Yayinda manyan abubuwa na iya buƙatar filin ƙarfi na 4000 – 5000 Taustar. Moti na riguna yana taimakawa wajen motsa kayan tare da tsarin allo, Yana ba da damar ƙwanƙolin ƙarfe da aka kama da kuma karkatar da su zuwa tarin tarin. Bugu da ƙari, Ana iya tsara girman allon allo, yawanci ci gaba daga 0.5 mm to 5 mm, Don kara gyara tsarin rabuwa da tabbatar da tsarkakakkiyar abubuwan da aka dawo da ƙarfe.

A ƙarshe, Resularancin kayan da ke da matukar mahimmanci a cikin sabon makamashi Egs na buƙatar haɗuwa da injin ƙi na musamman, Kowane ya dace da takamaiman halaye na kayan da ake amfani dashi. Idan kai kamfani ne ko kuma mutum yana sha'awar yin zurfin zurfafa cikin filin sabbin kayan aikin, ko kuma idan kuna da wasu tambayoyi game da zaɓi na kayan girke-girke, Tuntube mu don Allah. Teamungiyarmu tana nan don taimaka muku.

Yadda za a tabbatar da cewa tsarin sake amfani da hanyar vata shine frue-free

By implementing these pollution prevention measures, you can ensure that the waste car recycling process is environmentally friendly. We specialize in providing top-notch e-waste recycling solutions including dust removal. You can reach out to us via our contact form. We look forward to helping you enhance the environmental performance of your e-waste recycling business through our high-quality dust removal equipment.

How can recycling new energy vehicle parts bring you profits?

A 2025, Sake dawo da sabon sassan kayan aikin lantarki yana ba da babban alkawarin tattalin arziki. Kasuwancin sake sarrafawa na ci gaba yana taimakawa wajen buɗe darajar motocin da aka watsar da su.

Muna samar da kayan girke-girke na kwararru tare da Kowace ce da Iso takardar shaida. Hadayuwarmu sun hada da lithium – injin sayar da batir, SOLAR Panel Recycling kayan aiki, kewaye – Lines na sake amfani da layin, da Taya Pyrolysis m.

Idan kuna sha'awar sabon makamashi Ev Reycycling Kasuwanci da Rashin tabbas game da zaɓin kayan aiki, Tuntube mu ba tare da rashin jinkiri ba.

Tuntube mu