As the new energy electric vehicle (NEV) market continues to expand exponentially, the issue of vehicle recycling has emerged as a crucial aspect for the sustainable development of the industry. By 2025, እንደገና ጥቅም ላይ ማዋል ለአካባቢያዊ ጥበቃ አስፈላጊ ብቻ ሳይሆን ጠቃሚ ሀብቶች እና ኢኮኖሚያዊ ዕድሎች ምንጭንም እንጠብቃለን. ከሚያስጨንቀው የውጤት ህይወት ኔቪዎች ጋር, ትክክለኛ መልሶ ጥቅም ላይ ማዋል ዘዴዎች እና መሠረተ ልማት እየጨመረ የመጣው የተጣሉ ተሽከርካሪዎች ብዛት ያላቸውን መጠን ለማስተናገድ አስፈላጊ ነው.

የትኞቹን የኃይል ተሽከርካሪዎች ክፍሎች የትኞቹን ክፍሎች እንደገና ጥቅም ላይ መዋል ይችላሉ?

በአዲሱ የኃይል ኤሌክትሪክ ተሽከርካሪ ላይ እንደገና ጥቅም ላይ ሊውሉ የሚችሉ ዕቃዎች (NEV) ገጽታዎች

የመስክ ብርጭቆ የ NVs ሊደመሰስ እና እንደገና ጥቅም ላይ ሊውል ይችላል. ይህ ሂደት መስታወቱን ወደ ትናንሽ ቁርጥራጮች መሰባበርን ያካትታል, ከዚያ በኋላ ወደ አዲስ የመስታወት ምርቶች ሊነካ ይችላል, ለድንግል ጥሬ ዕቃዎች አስፈላጊነት መቀነስ.

በተጨማሪም, የመኪናው የሰውነት ፕላስቲኮች, ለብርሃን ክብደታቸው እና ዘላቂ ለሆኑ ንብረቶች በዘመናዊ የተሽከርካሪ ማምረቻ በሰፊው ጥቅም ላይ ይውላሉ, can be crushed and processed to yield economic benefits. These recycled plastics can be used in various industries, such as the production of plastic pellets for manufacturing new plastic components or in the construction industry for non-structural applications.

Recyclable materials inside energy electric automobiles

Lithium batteries in new energy battery electric vehicles (BEV) are a significant source of precious metals. These batteries contain elements like lithium, Cobal, nickel, and manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Lithium batteries in new energy battery electric vehicles (BEV) are a significant source of precious metals. These batteries contain elements like lithium, Cobal, nickel, and manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Which machines can recycle valuable materials in new energy EVs

When it comes to recycling the car shells of new energy EVs, heavy-duty shredding machines are essential. These shredders can handle the large and sturdy metal structures. ለምሳሌ, hydraulic crushers with a powerful motor can exert high pressure to break down the car bodies into smaller pieces. They usually have a large crushing chamber and adjustable jaws to accommodate different sizes of car parts. The power of such crushers can range from 50 kW to 150 KW, enabling them to efficiently process the thick metal sheets of the car shells.

For the recycling of window glass, specialized crushers are required. These crushers are often equipped with toughened blades and a vibrating feeder system. The blades are made of high-quality alloy to withstand the hardness of the glass. The vibrating feeder ensures a continuous and even supply of glass pieces to the crushing area. Some advanced glass crushers can achieve a crushing size as small as 1 – 5 ሚሜ, which is crucial for further processing and separation of the glass components. The power consumption of these crushers is relatively lower compared to those for car bodies, typically around 10 kW to 30 KW.

Circuit boards in new energy EVs contain valuable metals and components. Crushers designed for circuit boards need to be more precise and gentle to avoid damaging the precious materials. They usually employ a combination of mechanical shearing and impact forces. The crushers have fine-toothed rollers and a controlled crushing mechanism to break the circuit boards into small fragments while preserving the integrity of the metals and semiconductors. The power of these crushers is generally in the range of 20 kW to 50 KW.

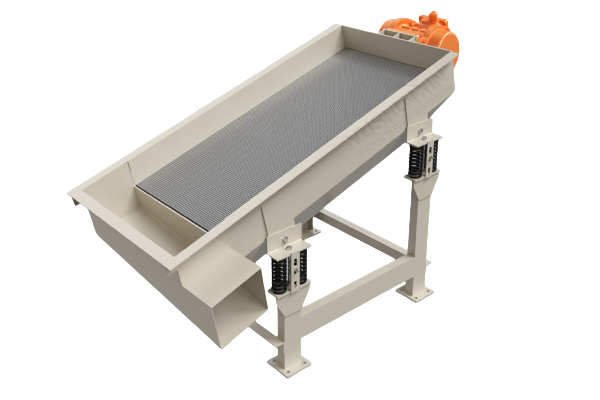

Vibrating screens with different mesh sizes are commonly employed. These screens can separate the crushed materials based on their particle size. ለምሳሌ, a vibrating screen with a mesh size of 2 – 10 mm can effectively sift out the aluminum particles from the non-metallic debris. The screening efficiency is crucial to ensure the purity of the recovered metal elements. Our screening machines are equipped with intelligent control systems to adjust the vibration frequency and amplitude, optimizing the separation process.

Magnetic vibrating screens are widely used for separating metal elements. These screens utilize the magnetic properties of metals to attract and separate them from the non-metallic materials. እነሱ አብሮገነብ ማግኔቶች እና ተለዋዋጭ ድግግሞሽ ድራይቭ ስርዓት ጋር የሚዛመድ የመርከቧን የመርከስ መምህር ያካተቱ ናቸው. የማግኔት መስክ ጥንካሬ በተመለሰው የብረት ቅንጣቶች ዓይነት እና መጠን ማስተካከል ይችላል. ለምሳሌ, ለአነስተኛ የብረት ቁርጥራጮች, መግነጢሳዊ መስክ ጥንካሬ 2000 – 3000 ጋስ በቂ ነው, ሰፋፊ ቁርጥራጮች ጠንካራ መስክ ሊፈልጉ ይችላሉ 4000 – 5000 ጋቶች. የሚንቀጠቀጡ እንቅስቃሴዎች ቁሳቁሶችን በማያ ገጽ ወለል ለማንቀሳቀስ ይረዳል, የብረት ቅንጣቶች በማግቴዎች እንዲያዙ እና ለተለየ ክምችት ጩኸት እንዲይዙ መፍቀድ. በተጨማሪም, የእኛ ማያ ገጽ መጠን መጠን ሊበጅ ይችላል, በተለምዶ ከ 0.5 mm ወደ 5 ሚሜ, የመለያየት ሂደቱን ለማጣራት እና የተመለሱት የብረት ንጥረ ነገሮች ንፅህናን ለማረጋገጥ.

ማጠቃለያ, በኒው የኃይል ቪዎች ውስጥ ዋጋ ያለው ቁሳቁሶችን እንደገና ጥቅም ላይ የዋለው እንደገና ጥቅም ላይ የዋሉ የመልሶ ማቋቋም ማሽኖች ጥምረት ይፈልጋል, each tailored to the specific characteristics of the materials being recycled. If you are an enterprise or individual interested in delving deeper into the field of new energy vehicle parts recycling, or if you have any questions regarding the selection of recycling equipment, contact us please. Our team is here to assist you.

How to ensure that the waste car recycling process is pollution-free

አዲስ የኃይል ተሽከርካሪዎች ክፍሎችን እንደገና ጥቅም ላይ ሊውሉ የሚችሉት እንዴት ነው??

In 2025, the recycling of new energy electric vehicle parts offers great economic promise. Advanced recycling technologies help unlock the value of discarded vehicles.

We manufacture professional recycling equipment with እዘአ እና ገለልተኛ ማረጋገጫዎች. Our offerings include lithium – battery recycling machines, solar panel recycling equipment, circuit – board recycling lines, እና tire pyrolysis production line equipment.

If you’re interested in the new energy EV recycling business and unsure about equipment choices, ያለምንም ማመንታት ያግኙን.

እኛን ያግኙን