Կան տարբեր տեսակներ 1 տոթ Անվադողերի պիրոլիզի վերամշակման համակարգեր, ներառյալ բջջային պիրոլիզի միավորները, Փաթեթ անվադողերի պիրոլիզի մեքենաներ, եւ շարունակական անվադողերի պիրոլիզի մեքենաներ. Յուրաքանչյուր տեսակը գործում է պիրոլիզի հիմնարար սկզբունքի հիման վրա, բայց գործընթացի հոսքի որոշ տարբերություններով.

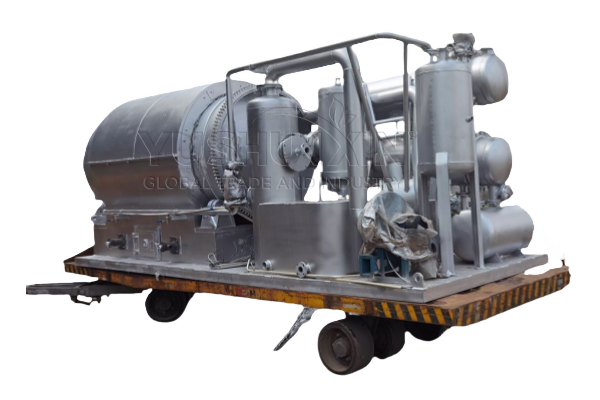

Բջջային անվադողերի պիրոլիզի միավոր

Անվադողերի բեռնում եւ պատրաստում

Բջջային պիրոլիզի միավորը նախատեսված է ճկունության համար եւ հեշտությամբ տեղափոխվում է տարբեր վայրեր. Թափոնների անվադողերը նախ բեռնված են շարժական սահադաշտի վրա տեղադրված անվադողերի պիրոլիզի մեքենայի վրա. Առաջ Պիրոլիզի գործընթացը սկսվում է, Անվադողերը կարող են մանրացված լինել ավելի փոքր կտորների մեջ, մակերեսային տարածքը բարձրացնելու եւ ավելի արագ եւ ավելի արդյունավետ պիրոլիզի հեշտացնելու համար. This shredding step is crucial as it allows for better heat transfer during the subsequent heating process.

Tyre Pyrolysis Chamber

Once the shredded tires are loaded into the pyrolysis chamber, the chamber is sealed to create an oxygen – free environment. This is essential because pyrolysis occurs in the absence of oxygen; otherwise, the tires would burn instead of undergoing pyrolysis. The chamber is then heated using a heat source, which could be the pyrolysis gas produced during the process itself or an external fuel source such as natural gas. As the temperature inside the chamber rises to around 400 – 600 degrees Celsius, the rubber in the tires starts to break down into smaller molecules.

Vaporization and Condensation in Tire Pyrolysis

The pyrolysis process generates a mixture of gases and vapors. These vapors are then directed towards a series of condensers. The condensers typically consist of long, coiled pipes or tubes, often made of materials with good heat-transfer properties such as stainless steel. As the hot vapors pass through the condensers, they come into contact with the cooler surfaces of the condenser tubes. The temperature of the vapors drops rapidly, causing them to condense into a liquid state. This liquid is the Պիրոլիի յուղ, which can be collected and further refined for use as a fuel or in other industrial applications.

Gas Separation in Tyre Pyrolysis

Not all of the pyrolysis products condense into liquid. Some remain in the gaseous state. These gases are passed through a gas separation system. This system may use filters and membranes to separate different types of gases. Օրինակ, lighter hydrocarbons such as methane and ethane can be separated from heavier gases. The separated gases can be used as a fuel to heat the pyrolysis chamber, creating a self – sustaining energy loop.

Collection of Carbon Black from Tires

After the pyrolysis process is complete, the solid residue left in the pyrolysis chamber is mainly carbon black. Է Ածխածնի սեւ is removed from the chamber and can be further processed to improve its quality. It can be used in various industries, such as rubber manufacturing, ink production, and as a filler in plastics.

Batch Tire Pyrolysis Machine

Batch Loading Waste Tires

In a batch tire pyrolysis equipment, a specific quantity of waste tires is loaded into the pyrolysis reactor at one time. The tires may be whole or pre-shredded, depending on the design of the machine. Once the reactor is filled, it is sealed to prevent the entry of oxygen.

Heating and Pyrolysis Tyre

The reactor is heated using a heating system. Similar to the mobile unit, the heat can be provided by the pyrolysis gas or an external fuel. As the temperature increases, the tires start to decompose. The pyrolysis process in a batch machine may take several hours, depending on the size of the batch and the operating temperature.

Recovery of Tire Pyrolysis Byproducts

During the pyrolysis process, the generated vapors and gases are led to the condenser system. The condenser, with its network of tubes, cools the vapors to form Անվադողերի պիրոլիզի յուղ. The non – condensable gases are separated and can be reused as fuel. After the pyrolysis reaction is completed, the carbon black is removed from the reactor. One of the characteristics of a batch system is that it needs to be unloaded and reloaded with a new batch of tires after each cycle, which may cause some downtime between batches.

Continuous Tire Pyrolysis Equipment

Continuous Tire Feeding

A continuous tire pyrolysis recycling line is designed for high-volume and continuous operation. Waste tires are continuously fed into the pyrolysis reactor through a conveyor system. This ensures a steady supply of raw materials and allows for a more efficient and continuous production process.

Continuous Tyre Pyrolysis Process

The tires move through the reactor as it is heated. The temperature is carefully controlled along the length of the reactor to ensure that the pyrolysis process occurs evenly. As the tires progress through the reactor, they are gradually broken down into pyrolysis products.

Condensation and Product Separation

The vapors and gases produced during the continuous pyrolysis process are continuously directed to the condenser. The condenser, with its long and efficient cooling tubes, quickly condenses the vapors into pyrolysis oil. The non – condensable gases are separated and used for heating. The carbon black is continuously removed from the end of the reactor. This continuous operation mode results in higher productivity compared to batch systems, as there is no need to stop the process for loading and unloading.

Whether it is a mobile, batch, or continuous 1 տոթ Թափոնների անվադողերի վերամշակման արտադրության գիծ, they all rely on the principle of pyrolysis to convert waste tires into useful products. The differences lie in the mode of operation, loading and unloading methods, and overall productivity, which can be selected according to your production needs and site conditions.

Կապվեք մեզ հետ