Awọn paati akọkọ ti fọtovoltaic (PV) oorun nronu oriširiši ga-didara gilasi, aluminiomu awọn fireemu, polima, ohun alumọni, iṣuu kọpa, ati fadaka lẹẹ. Nipa ẹrọ atunlo awọn paneli oorun wa (awọn ojutu), o le ṣaṣeyọri atunlo ọkọọkan awọn ohun elo wọnyi, pẹlu gbigba awọn ošuwọn nínàgà soke si 95%.

Iru awọn paneli oorun wo ni a tun lo?

Ti o ko ba ri nkan e-egbin rẹ(s) akojọ si loke, jọwọ kan si wa. YSX yoo ran ọ lọwọ.

PV Panel Frame Dismantling Machine

Awọn oorun photovoltaic nronu deframing ẹrọ ni o dara fun awọn dismantling ati atunlo ti alokuirin oorun nronu aluminiomu awọn fireemu ti awọn orisirisi titobi ati awọn iru. Ni ibẹrẹ, o le ṣe afojusun gangan ati bẹrẹ ilana ti yiya sọtọ fireemu aluminiomu. Lẹhinna, lakoko isẹ yii, o ṣakoso lati nipari yọ kuro 80%-95% ti gilasi.

Oorun Panels Gilasi yiyọ Machine

Yiyọ julọ ti gilasi lati dada. Sise Iwọn 1250mm.

Oorun Panels Meji-ọpa Shredder

Shredder le lakoko ilana titobi nla ti oorun paneli. Ni ibẹrẹ, o yara fọ wọn si awọn ege kekere, nitorina imudarasi ṣiṣe ti gbogbo laini atunṣe atunlo. Lẹhinna, the smaller material size makes the subsequent equipment (such as sorters, crushers, etc.) work more efficiently.

Crusher (Hammer Mill) for Photovoltaic Panels

After shredding, the fragmented materials are passed through a crusher. This machine is designed to further break down materials like glass, silicon wafers, and other components into even smaller particles. Crushing is a critical step in the recycling process as it prepares the materials for separation techniques that will isolate valuable metals and silicon.

What Solar Panel Recycling Machine Sorts Those Materials?

Magnetic Separator

Used to separate iron and other magnetic metals from mixed materials. Magnetic separator uses the attraction of a magnetic field to separate magnetic metals from non-magnetic materials, thereby improving the purity of the material.

Cyclone separator

Cyclone separator is a highly efficient device that employs centrifugal force to effectively separate lighter materials from heavier ones within a mixture. As the mixture is introduced into the cyclone separator, it undergoes rapid spinning, which generates a powerful vortex inside the chamber. This vortex action causes the heavier particles to be flung outward towards the outer edges of the separator. Lẹhinna, the lighter materials are allowed to stay near the center. As a result, a clear and efficient separation process is facilitated.

High-voltage electrostatic separator

The remaining copper and EVA glue that are not completely separated enter the high-voltage electrostatic separator, which separates the copper based on conductivity.

Gravity Separator

Gravity separator jẹ ohun elo imotuntun ti o ni imunadoko yapa bàbà ati lẹ pọ EVA ti o da lori awọn iwuwo oriṣiriṣi ti awọn patikulu wọn. Nipa lilo ilana ti walẹ, Iyapa yii ṣe iyatọ awọn ohun elo pẹlu awọn iwuwo oriṣiriṣi. Ni ibẹrẹ, o fara ya awọn orisirisi irinše ti egbin oorun paneli. Nipasẹ ilana yii, impurities ti wa ni significantly dinku. Keji, Imudara yii ni mimọ yoo yori si ilọsiwaju akiyesi ni ṣiṣe ati deede ti ilana atunlo.. As a result, oṣuwọn ilotunlo ti awọn paneli oorun egbin ti pọ si ni pataki. Dajudaju, it contributes to more sustainable and eco – friendly practices in the management and recycling of solar panel materials.

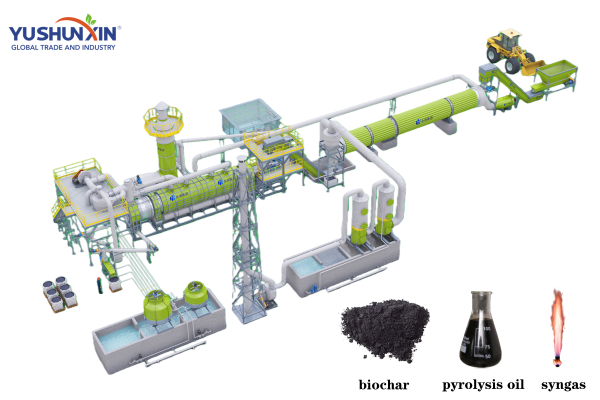

Kini Ẹrọ Atunlo Panel Oorun wa ninu Ilana Itọju Ooru?

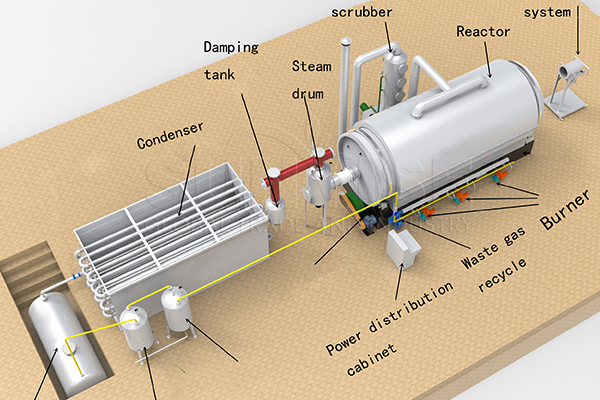

Awọn Pyrolysis ileru creates a high – temp, oxygen – free space. Oorun paneli ti wa ni kikan si 600°C, nfa awọn ohun elo ti bajẹ. Diẹ ninu awọn yipada si gaasi, nlọ slag pẹlu eru awọn irin nilo afikun itọju. Awọn tube condensing iyipada gaasi si omi bibajẹ. Awọn gaasi Iyapa package purifies gas – liquid mixtures. Awọn sokiri ẹṣọ Fọ eefi ategun, idinku idoti ati ipade awọn ajohunše.

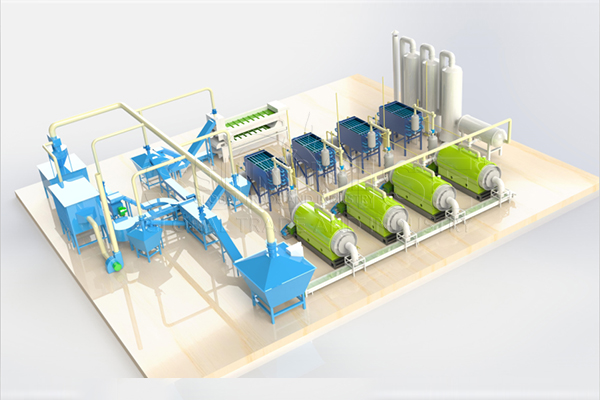

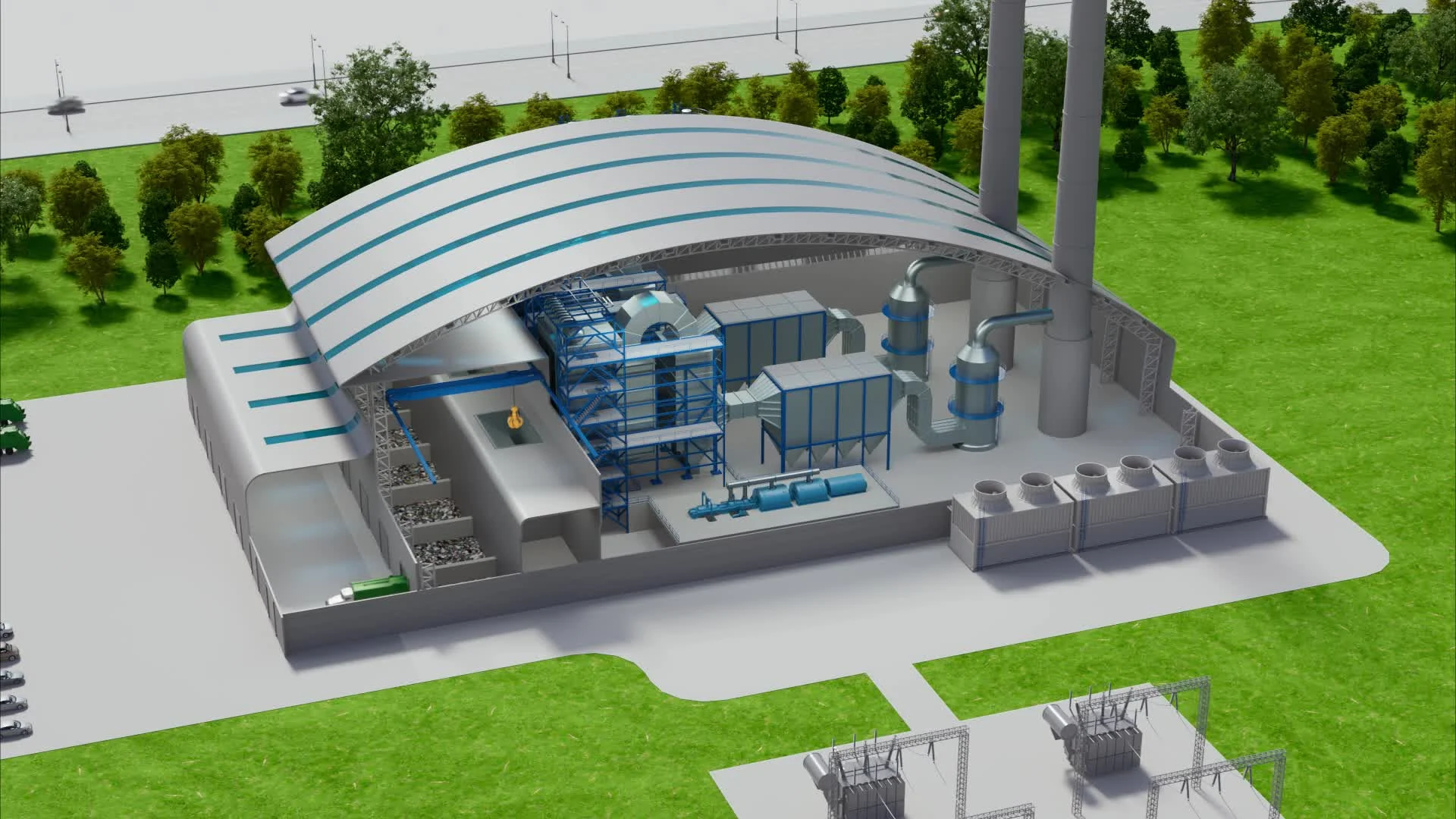

Bii o ṣe le ṣe apẹrẹ Ile-iṣẹ Atunlo Panel Oorun?

Kí ni Eniyan Tunlo Solar Panels fun?

Kini idi ti Yan YUSHUNXIN gẹgẹbi Olupese Rẹ ti Awọn Ẹrọ Atunlo Panel Oorun?

Awọn anfani ti YSX Solar Panel Awọn ẹrọ Atunlo

Awọn paramita ohun elo atunlo nronu oorun fun itọkasi rẹ

| Awoṣe | YSX-300 | YSX-500 | YSX-1000 |

| Agbara | 300 Kg/H | 500 Kg/H | 1000 Kg/H |

| Agbara | 102 Kw | 134 Kw | 194 Kw |

| Iwọn | 15 Toonu | 20 Toonu | 30 Toonu |

| Iwọn (m) | 20*5*5 | 25*6*5 | 30*6*5 |

Kini idiyele Gbogbogbo ti Laini Atunlo Panel Oorun?

Approximately $50,000 – $70,000. Small-scale lines are suitable for small to medium enterprises or startups, relatively simple and low-cost.

Approximately $80,000 – $150,000. In addition to the equipment in small-scale lines, medium-scale lines require higher-specification equipment. Medium-scale lines require more efficient equipment and automation systems to handle medium-scale processing needs.

Approximately $160,000 – $200,000 or more. Large-scale lines need the most advanced equipment and systems to maximize recycling efficiency and environmental compliance.

Pe wa