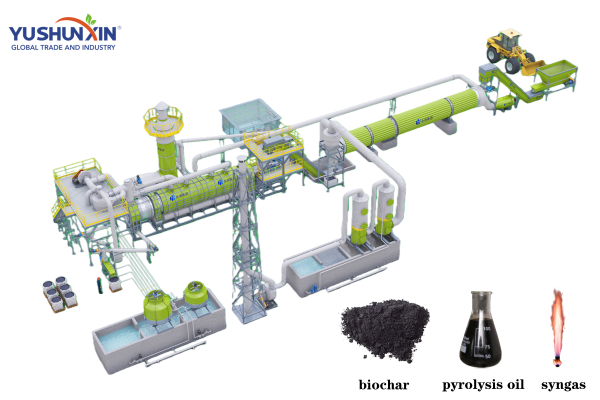

Waste sludge is no longer just a disposal problem—it’s a hidden source of valuable resources. Modern pyrolysis plants can efficiently convert sludge into high-value oil, gas, and carbon products, turning waste into profit. Whether for industrial, municipal, or chemical applications, these plants offer not only cost savings and regulatory compliance but also renewable energy generation, helping businesses maximize revenue while staying eco-friendly. But how to treat waste sludge? We can provide you some solutions for your choice.

What Is the Process of Waste Sludge Pyrolysis?

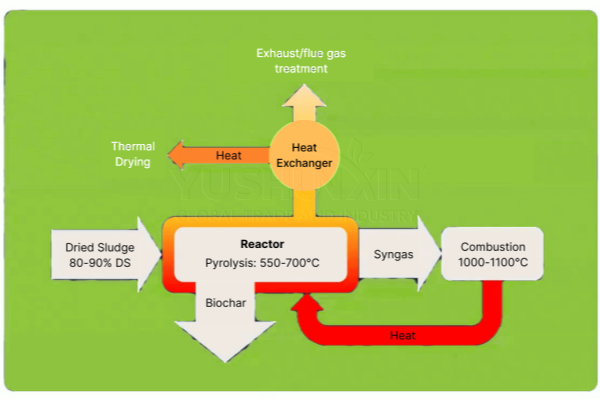

The waste sludge pyrolysis process converts high-moisture sludge into fuel, carbon products, and clean gas. Proper pre-treatment and precise control of drying and pyrolysis conditions are essential to ensure efficiency and product quality.

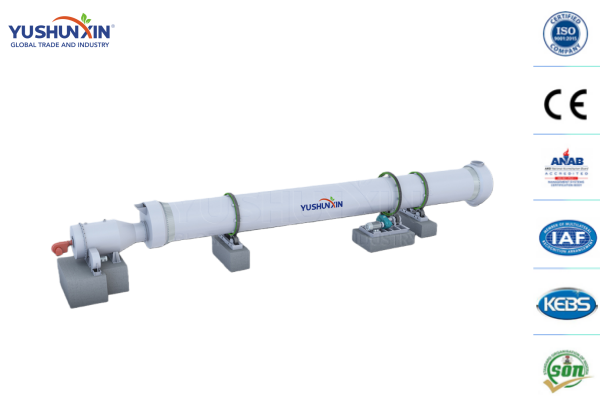

The first step removes excess water from sludge. The sludge first enters a rotary drum dewatering machine to remove excess water. The drum rotates continuously while internal screens and pressure separate solids from liquids. This process reduces moisture from 80% to around 60%, creating a stable feed for the next stage. Because the machine operates continuously, it handles large volumes without interruption. Adjustable drum speed and pressure allow operators to optimize performance based on sludge thickness. Effective dehydration lowers energy consumption in the drying stage and prevents material clumping.

After dewatering, the sludge moves into a rotary drum dryer for deeper moisture reduction. The dryer uses 120–150°C hot air to evaporate water while the rotating drum lifts, scatters, and heats the material evenly. Residence time typically ranges from 20–40 minutes, depending on moisture content. This process reduces water levels from 60% to below 10%, preparing the sludge for efficient pyrolysis. Stable airflow, controlled temperature, and continuous feeding ensure uniform drying, prevent overheating, and maintain the quality of organic components.

Finally, The dried sludge enters a sealed pyrolysis reactor and heats up to 400–600°C in an oxygen-free environment. At this temperature, organic compounds break down quickly into oil vapor, syngas, and solid carbon. The sludge stays in the reactor for 30–60 minutes, allowing full cracking and volatilization. Indirect heating and internal spiral blades ensure even temperature distribution. Part of the syngas returns as burner fuel, reducing energy use, while the remaining gas and oil vapor move to the condenser for recovery.

What Valuable Products Can You Get from Waste Sludge Pyrolysis?

Waste sludge pyrolysis creates multiple commercial products. Each output has clear economic value, allowing businesses to recover costs and generate profit while maintaining environmental compliance.

How Quickly Can You Recover Your Investment from a Waste Sludge Pyrolysis Plant?

The payback period of a waste sludge pyrolysis plant depends on plant capacity, product value, and daily operating costs. With stable sludge supply and consistent product sales, many investors recover their initial capital faster than traditional waste treatment solutions.

In total, operators can earn $300–900 per ton of treated sludge, depending on local markets. Reduced disposal and energy costs accelerate ROI and make pyrolysis a profitable long-term investment.

How Does a Waste Sludge Pyrolysis Machine Meet Emission Standards?

Regulatory compliance is critical for sludge pyrolysis. Modern machines adopt gas cleaning and control systems to reduce pollutants, ensuring emission standards are met without compromising process efficiency.

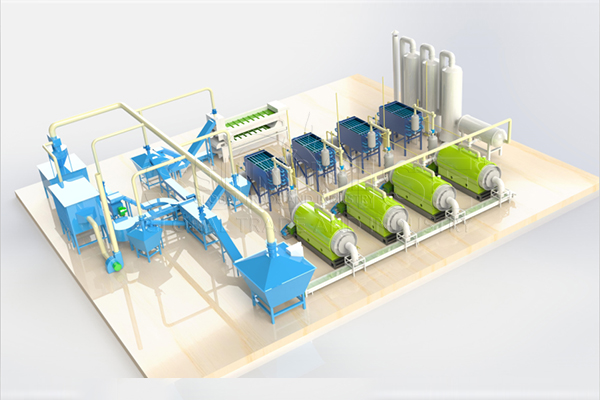

Waste Sludge Treatment Solutions for Manufacturing, Mining & Oil Fields

Different industries produce sludge with varying compositions. Pyrolysis technology adapts to these variations, providing effective solutions for manufacturing, mining, and oil field operations while turning waste into valuable resources.

Manufacturing plants generate sludge from chemical processing, textile dyeing, paper production, and food processing. This sludge often contains organics, fibers, oils, and chemical residues. Pyrolysis stabilizes these materials and converts them into usable energy. The process reduces waste volume by more than 60–70%, which significantly lowers disposal costs. Factories can reuse pyrolysis oil in boilers or sell it as an industrial fuel. Meanwhile, char can serve as a solid fuel or be added to construction materials. This creates a circular and sustainable waste management system.

Mining operations produce sludge containing fine minerals, organic residues, heavy metals, and flotation chemicals. Traditional disposal methods cost a lot and create long-term environmental risks. Pyrolysis offers a cleaner alternative by breaking down organic compounds and reducing sludge toxicity. The process generates syngas for on-site heating and char for metallurgical use. Pyrolyzed char can also assist in soil remediation around mining sites because it stabilizes heavy metals. With reduced waste volume and regained energy, mining companies improve both environmental compliance and operational efficiency.

Oil-field sludge contains hydrocarbons, drilling fluids, paraffin, and solid particles. This type of sludge poses high environmental and handling risks. Pyrolysis recovers 15–25% crude-like oil, which can be reused in drilling operations or refined for industrial fuel. Syngas supports the plant’s heating system, reducing energy consumption. The remaining solid carbon becomes a safe, low-toxicity product suitable for construction or fuel blending. Because pyrolysis eliminates harmful hydrocarbons and minimizes waste mass, oil companies achieve regulatory compliance and lower treatment costs while recovering valuable energy resources.

Besides, waste sludge pyrolysis solution, we also can provide you with many other waste disposal systems. Such as waste tire pyrolysis plant, waste plastic pyrolysis line, etc. Welcome to contact us for your own e-waste recycling plan immediately.

Contact Us