E ere faahou te sludge i te hoê fifi noa—te hoê pu huna no te mau tao'a faufaa. E nehenehe te mau tumu raau pyrolysis e taui maitai i te taheraa toto ei hinu faufaa rahi, i'a, e te mau tao'a tahi, e faaino i te moni. No te ohipa tapihooraa, ōhipa, mai te mea, E ere teie mau tumu raau i te mea noa e e aufau noa i te mau haamau'araa e te mau ravea faatere, te tauturu i te mau taiete ia faarahi i te moni a vai noa ai te mau mea e haaati ra i te fenua. Teie râ, nafea ia rapaau i te mau hu'ahu'a? E nehenehe ta matou e horo'a ia outou i te tahi mau rave'a no ta outou maitiraa.

Eaha te mea e tano no te Pyrolysis?

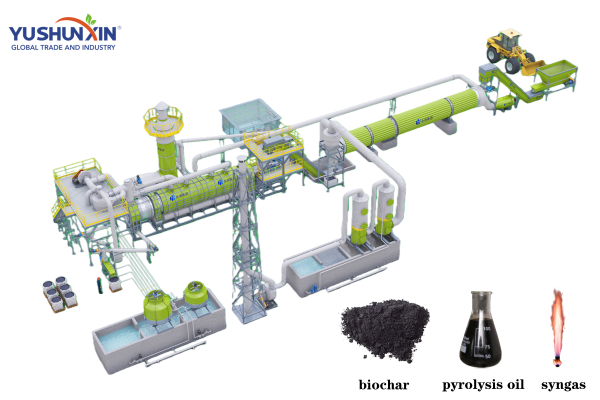

E taui te huru o te mau hu'ahu'a i te mau hu'ahu'a pyrolysis e taui i te hu'ahu'a teitei i roto i te hinu, te mau tao'a, e te hoê mǎhu mâ. No te haapapû i te maitai e te huru o te mau tao'a, e mea faufaa roa ia haapa'o i te mau huru no te faaetaaraa e te mau huru o te pyrolysis.

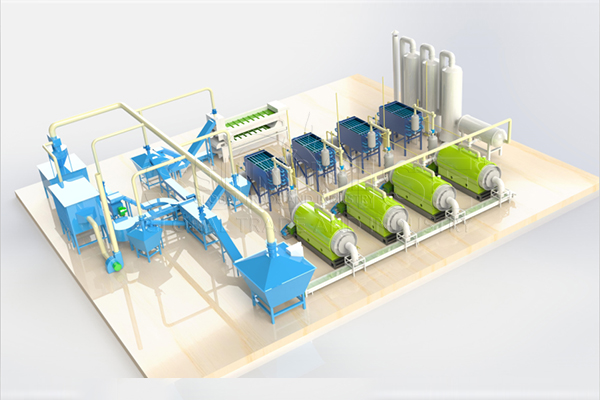

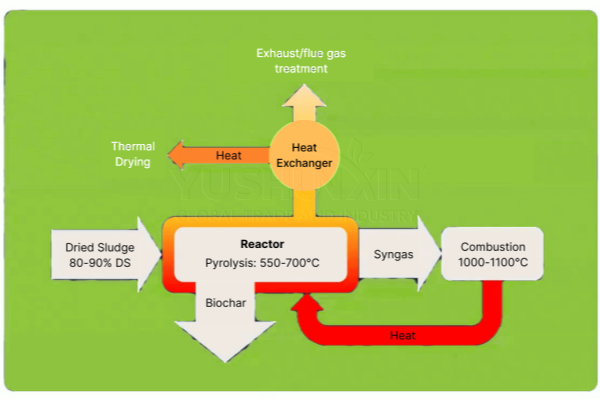

E iriti te taahiraa matamua i te pape hau atu i te repo. No te iriti i te pape hau atu i te pape, e tomo na mua te pape i roto i te hoê ravea parariraa.. E taui tamau noa te reo i roto i te mau hoho'a i roto e te faaheporaa taa ê i te mau tao'a etaeta i roto i te mau pape. E faaiti teie ohipa i te haumi 80% i te tahi a'e 60%, Te hoê vahi faaearaa no te taahiraa i muri iho. No te mea e ohipa tamau noa te ravea, te faatere nei te reira i te mau buka rahi ma te ore e tapea. Ma te faaohipa i te vitiviti e te faaheporaa, e nehenehe te mau taata faatere e haamaitai i te ohipa i nia i te matotoraa o te hu'ahu'a. E faaiti te ereraa i te pape i te ito i roto i te taime maro e e arai i te mau tao'a.

I muri a'e i to ' na pepe-raa-hia, e haere te sludge i roto i te hoê re'are'a toto no te faaiti i te haumi hohonu a'e. E faaohipa te pape pu'e i te 120–150°C no te faaî i te pape i te pape pu'e, ha'api'ira'a, e te faahanahana ra te mau tao'a i te. I te rahiraa o te taime, e 20–40 minuti to te reira, ua. E faaiti teie ohipa i te faito o te pape no roto mai i te 60% i raro 10%, no te faaineine i te repo no te mau pyrolysis. mā'ohi, Te anuvera iti, e te maa tamau no te haamaitai i te hoê â, Eita e nehenehe e faaauhia no te mea e e nehenehe te mau epikopo., e te tapearaa i te mau tuhaa o te mau mea ora.

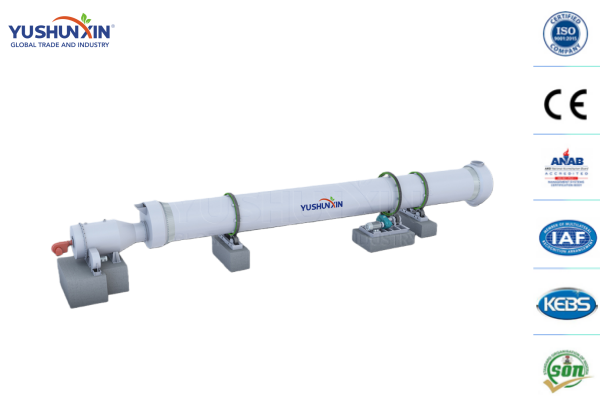

ʻIa, E tomo te hu'ahu'a maro i roto i te hoê rave'a haaparareraa parau e te ve'ave'a e tae roa'tu i te 400–600°C i roto i te hoê vahi aita e pape. I teie anuvera, E vavahi-oioi-hia te mau tao'a tahi ora, i'ā, and solid carbon. The sludge stays in the reactor for 30–60 minutes, allowing full cracking and volatilization. Indirect heating and internal spiral blades ensure even temperature distribution. Part of the i'ā returns as burner fuel, reducing energy use, while the remaining gas and oil vapor move to the condenser for recovery.

What Valuable Products Can You Get from Waste Sludge Pyrolysis?

Waste sludge pyrolysis creates multiple commercial products. Each output has clear economic value, allowing businesses to recover costs and generate profit while maintaining environmental compliance.

Nahea e ti'a ai ia outou ia ite oioi i ta outou moni i roto i te hoê faanahoraa no te faanahoraa i te pape?

Te faataahia ra te tau faaho'iraa o te hoê fare hamaniraa tauihaa pyrolysis i nia i te aravihi o te mau tumu raau, rahi, e te moni hoo i te mau mahana atoa. Na roto i te hooraa i te mau tao'a e te mau tao'a tamau, many investors recover their initial capital faster than traditional waste treatment solutions.

In total, operators can earn $300–900 per ton of treated sludge, depending on local markets. Reduced disposal and energy costs accelerate ROI and make pyrolysis a profitable long-term investment.

How Does a Waste Sludge Pyrolysis Machine Meet Emission Standards?

Regulatory compliance is critical for sludge pyrolysis. Modern machines adopt gas cleaning and control systems to reduce pollutants, ensuring emission standards are met without compromising process efficiency.

Te mau rave'a no te rapaauraa i te ma'i, Mining & Oil Fields

E faatupu te mau taiete e rave rau i te hoê vahi iti e te mau haamauraa huru rau. E au te mau rave'a aravihi apî i teie mau taa-ê-raa, te horoaraa i te mau ravea aravihi no te hamani i te, Te mau mana'o tauturu no te, and oil field operations while turning waste into valuable resources.

Manufacturing plants generate sludge from chemical processing, textile dyeing, paper production, and food processing. This sludge often contains organics, fibers, oils, and chemical residues. Pyrolysis stabilizes these materials and converts them into usable energy. The process reduces waste volume by more than 60–70%, which significantly lowers disposal costs. Factories can reuse pyrolysis oil in boilers or sell it as an industrial fuel. A tia'i noa'tu ai, char can serve as a solid fuel or be added to construction materials. This creates a circular and sustainable waste management system.

Mining operations produce sludge containing fine minerals, organic residues, heavy metals, and flotation chemicals. E mea rahi te mau rave'a no te faaore i te mau fifi e te mau rave'a no te faatupu i te mau fifi i te pae no te taiao. E horoa te pyrolysis i te hoê tauiraa oioi a'e na roto i te vavahiraa i te mau tao'a tahi ora e te faaitiraa mai i te mau hu'ahu'a. E faatupu te reira i te mau hoho'a no te faahanahana i te mau rave'a haaparareraa parau e te char no te faaohipa i te mau hu'ahu'a. E nehenehe atoa te yrolyze e tauturu i roto i te rapaauraa i te repo i nia i te mau vahi maimiraa no te mea te haamau ra te reira i te mau metala teimaha. Te faaitiraa i te rahi o te mau hu'ahu'a e te ito i faaho'i - faahou - hia, te faaitiraa i te aravihi no te mau mea e haaati ra ia tatou e te aravihi o te ohipa.

Te vai ra i roto i te mau hu'ahu'a hinu i roto i te mau hu'ahu'a, ha'avi'i, Faʻafaipo; no'i, e te mau hu'ahu'a. Te mau fifi rahi o te mau mea e haaati ra ia tatou e te mau ravea apî. E ora mai te pyrolysis i te 15–25% o te hinu, o te nehenehe e faaohipa - faahou - hia i roto i te mau ohipa faaapu aore ra e faaho'i - faahou - hia no te hinu. Te turu ra te mau syngas i te faanahoraa no te faahanahana i te tumu raau, ma te faaiti i te faaohiparaa i te ito. Ua riro te toea o te carbone ei vahi paruruhia, te faito iti o te tao'a e faaohipahia no te patu e aore râ, no te hamaniraa i te hinu. No te mea e faaore te pyrolysis i te mau hydrocarbons ino e e faaiti i te rahiraa o te mau hu'ahu'a, E fana'o te mau taiete hinu i te mau haamâu'araa no te rapaauraa e te faaitiraa mai i te mau ravea rapaauraa ma te faaho'i faahou mai i te mau ravea faufaa no te ito.

Roa, te hoê faatitiaifaroraa pyrolysis, e nehenehe atoa ta matou e horo'a ia outou i te tahi atu mau rave'a no te faaore i te mau hu'ahu'a. Tā'ore'a te hoê fare hamaniraa tauihaa pyrolysis, te mau hu'ahu'a pyrolysis pyrolysis, e te tahi atu â. Aroha mai no te farerei ia matou no ta outou iho opuaraa faaho'i-faahou-raa.

A farerei mai ia matou