Starting a tyre recycling business in South Africa gives you a chance to turn waste into profit. The country faces serious tyre disposal issues, but growing environmental awareness and strong market demand create excellent opportunities. With the right plan and equipment, you can build a sustainable and profitable business.

What is the Industry Overview and Opportunities of Tyre Recycling Business?

Tyre Waste Situation and Environmental Challenges

South Africa produces thousands of tons of waste tyres every year, and many end up in open fields or illegal dumps. These tyres release toxic substances and create fire hazards, making recycling an urgent need. As more people become aware of environmental risks, tyre recycling has gained public and political attention. You can use this momentum to enter a market that not only offers profit but also supports community welfare and cleaner cities.

Government Policies and Market Potential

The South African Waste Act and related recycling regulations encourage responsible waste management. You can apply for environmental licenses and even receive tax incentives or funding support for eco-friendly businesses. At the same time, the market for recycled products keeps expanding. Granul karét, playground mats, and pyrolysis oil are in strong demand both locally and abroad. By combining legal compliance with efficient production, you can establish a trusted and profitable recycling brand.

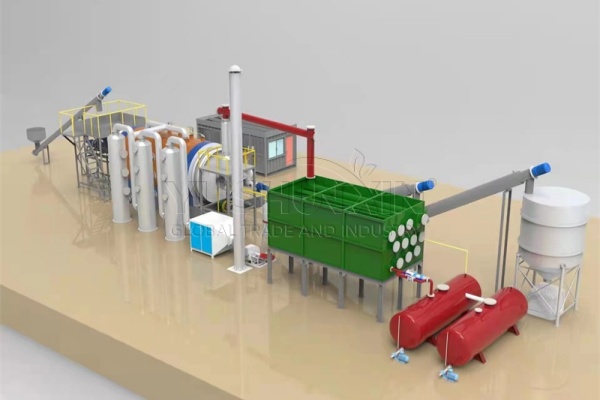

How to Design Tire Recycling Plant in South Africa?

Establishing a tyre recycling business in South Africa requires careful preparation. You need to evaluate your budget, research the market, and design a layout that supports efficient production. Because a clear plan helps you avoid delays, stay compliant, and reach profitability faster.

What Is the Tyre Recycling Process in South Africa?

Starting the recycling process requires you to understand how tyres are broken down and how each part is recovered. Efficient processing allows you to maximize material value and reduce environmental impact. With proper design, you can turn waste tyres into profitable products that serve industrial and energy markets.

How Profitable Is Tyre Recycling in South Africa?

Starting a tyre recycling business requires an initial investment, but the strong market for recycled materials ensures steady profits. By managing your costs wisely and choosing efficient equipment, you can reach profitability quickly and maintain stable growth.

Taros Kami