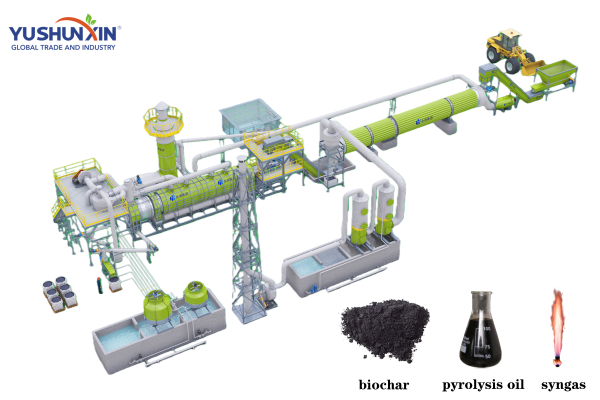

Matlakala a litšila ha e sa le bothata ba ho lahla feela—ke mohloli o patehileng oa lisebelisoa tsa bohlokoa. Limela tsa sejoale-joale tsa pyrolysis li ka fetola seretse hore e be oli ea boleng bo holimo, khase, le lihlahisoa tsa carbon, ho fetola litšila hore e be phaello. Ebang ke tsa indasteri, mmasepala, kapa lisebelisoa tsa lik'hemik'hale, limela tsena fana eseng feela ka chelete ea ho boloka litšenyehelo le ho latelwa taolo empa hape le tlhahiso ea matla a tsosolositsoeng, ho thusa likhoebo ho eketsa chelete e kenang ha li ntse li lula li boloka tikoloho. Empa mokhoa oa ho tšoara litšila tse litšila? Re ka u fa litharollo bakeng sa khetho ea hau.

Mokhoa oa Ts'ebetso ea Litšila Pyrolysis ke Efe?

Ts'ebetso ea pyrolysis ea litšila e fetola litšila tse nang le mongobo o phahameng hore e be mafura, lihlahisoa tsa carbon, le khase e hloekileng. Phekolo e nepahetseng ea pele le taolo e nepahetseng ea ho omisa le maemo a pyrolysis a bohlokoa ho netefatsa katleho le boleng ba sehlahisoa..

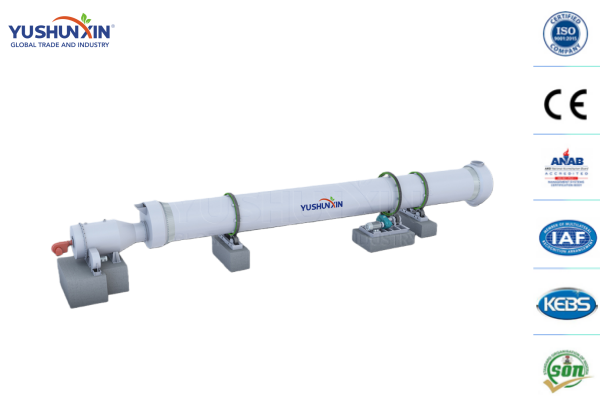

Mohato oa pele o tlosa metsi a mangata ho tsoa ho seretse. Seretse se qala ka ho kena mochineng oa rotary drum dewatering ho tlosa metsi a mangata. Moqomo o ntse o potoloha ha li-skrini tsa ka hare le khatello li arola lintho tse tiileng ho metsi. Ts'ebetso ena e fokotsa mongobo ho tloha 80% ho pota-pota 60%, ho theha phepelo e tsitsitseng bakeng sa mothati o latelang. Hobane mochini o sebetsa o sa khaotse, e sebetsana le meqolo e meholo ntle le tšitiso. Lebelo le ka feto-fetohang la moropa le khatello li lumella basebelisi ho ntlafatsa ts'ebetso ho latela botenya ba seretse. Ho felloa ke metsi 'meleng ka katleho ho theola tšebeliso ea matla nakong ea ho omisa le ho thibela ho putlama ha lintho.

Ka mor'a ho nosetsa, seretse se kena ka har'a mochini o omisang meqomo oa rotary bakeng sa phokotso e tebileng ea mongobo. Se omisang se sebelisa moea o chesang oa 120–150°C ho etsa mouoane oa metsi ha moropa o potolohang o phahamisa., hasanya, mme e futhumatsa thepa ka ho lekana. Nako ea bolulo hangata e tloha metsotso e 20-40, ho itshetlehile ka mongobo. Mokhoa ona o fokotsa maemo a metsi ho tloha 60% ho ea tlase 10%, ho lokisa seretse bakeng sa pyrolysis e sebetsang hantle. Phallo ea moea e tsitsitseng, mocheso o laoloang, le phepo e tsoelang pele e netefatsa ho omisa ho tšoanang, thibela mocheso o feteletseng, le ho boloka boleng ba likarolo tsa tlhaho.

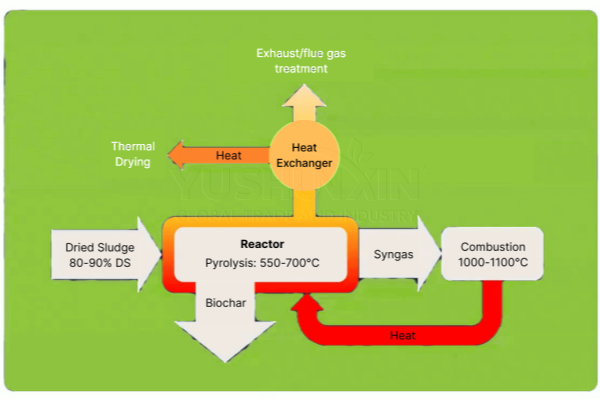

Qetellong, Seretse se omisitsoeng se kena ka har'a sets'oants'o sa pyrolysis se tiisitsoeng 'me se chesa ho fihlela ho 400-600 ° C sebakeng se se nang oksijene.. Ka mocheso ona, metsoako ea lintho tse phelang e robeha kapele ho ba mouoane oa oli, syngas, le carbon e tiileng. Seretse se lula ka har'a reactor bakeng sa metsotso e 30-60, ho dumella ho petsoha ka botlalo le ho tsitsinyeha. Mocheso o sa tobang le li-spiral blades tse ka hare li netefatsa hore mocheso o ajoa. Karolo ea syngas e khutla joalo ka libeso, ho fokotsa tshebediso ya matla, ha khase e setseng le mouoane oa oli li fallela ho condenser bakeng sa ho hlaphoheloa.

U ka Fumana Lihlahisoa life tsa Bohlokoa ho tsoa ho Waste Sludge Pyrolysis?

Waste sludge pyrolysis e etsa lihlahisoa tse ngata tsa khoebo. Sehlahisoa se seng le se seng se na le boleng bo hlakileng ba moruo, ho lumella likhoebo ho khutlisa litšenyehelo le ho hlahisa phaello ha li ntse li boloka tumellano ea tikoloho.

U ka Fumana Ka Potlako Hakae Hore U Tsoele Letsete la Hao ho Semela sa Waste Sludge Pyrolysis?

Nako ea ho lefa ea semela sa sludge pyrolysis e itšetlehile ka matla a semela, boleng ba sehlahisoa, le litšenyehelo tsa letsatsi le letsatsi tsa ts'ebetso. Ka phepelo ea seretse e tsitsitseng le thekiso e tsitsitseng ea lihlahisoa, batsetedi ba bangata ba hlaphoheloa motse-moholo oa bona oa pele ka potlako ho feta litharollo tsa setso pheko ea litšila.

In total, operators can earn $300–900 per ton of treated sludge, depending on local markets. Reduced disposal and energy costs accelerate ROI and make pyrolysis a profitable long-term investment.

How Does a Waste Sludge Pyrolysis Machine Meet Emission Standards?

Regulatory compliance is critical for sludge pyrolysis. Modern machines adopt gas cleaning and control systems to reduce pollutants, ensuring emission standards are met without compromising process efficiency.

Waste Sludge Treatment Solutions for Manufacturing, Mining & Oil Fields

Different industries produce sludge with varying compositions. Pyrolysis technology adapts to these variations, providing effective solutions for manufacturing, mining, and oil field operations while turning waste into valuable resources.

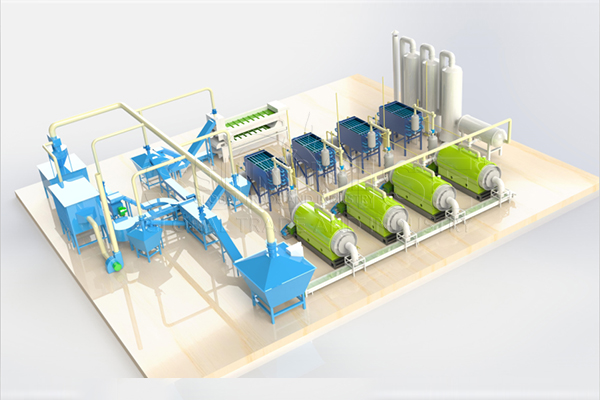

Manufacturing plants generate sludge from chemical processing, textile dyeing, paper production, and food processing. This sludge often contains organics, likhoele, oils, and chemical residues. Pyrolysis stabilizes these materials and converts them into usable energy. The process reduces waste volume by more than 60–70%, which significantly lowers disposal costs. Factories can reuse pyrolysis oil in boilers or sell it as an industrial fuel. Khabareng, char can serve as a solid fuel or be added to construction materials. This creates a circular and sustainable waste management system.

Mining operations produce sludge containing fine minerals, organic residues, heavy metals, and flotation chemicals. Traditional disposal methods cost a lot and create long-term environmental risks. Pyrolysis offers a cleaner alternative by breaking down organic compounds and reducing sludge toxicity. The process generates syngas for on-site heating and char for metallurgical use. Pyrolyzed char can also assist in soil remediation around mining sites because it stabilizes heavy metals. With reduced waste volume and regained energy, mining companies improve both environmental compliance and operational efficiency.

Oil-field sludge contains hydrocarbons, drilling fluids, paraffin, and solid particles. This type of sludge poses high environmental and handling risks. Pyrolysis recovers 15–25% crude-like oil, which can be reused in drilling operations or refined for industrial fuel. Syngas supports the plant’s heating system, reducing energy consumption. The remaining solid carbon becomes a safe, low-toxicity product suitable for construction or fuel blending. Because pyrolysis eliminates harmful hydrocarbons and minimizes waste mass, oil companies achieve regulatory compliance and lower treatment costs while recovering valuable energy resources.

Besides, waste sludge pyrolysis solution, we also can provide you with many other waste disposal systems. Joalo ka waste tire pyrolysis plant, waste plastic pyrolysis line, Etc. Welcome to contact us for your own e-waste recycling plan immediately.

Iteanye le rona