Dul saaran 24 Oktoobar, Waxaan helnay baaritaan ka soo baxa macmiilka Jarmalka ee ku saabsan Qashinka TIRE Pyrolysis warshad dib-u-warshadaynta Jarmalka. Macmiilku wuxuu doonayaa inuu waxbadan ka ogaado taayirrada qashinka ysx Mashiinnada Pyrolysis. Sababtoo ah Jarmalka ayaa bixiya kabitaan dhaqaale iyo dhiirrigelinta dib-u-warshadaynta, Oo Jarmalku wuxuu soo saaraa malaayiin taayirro sanadkii, sidaa darteed waxay leeyihiin dhibaato maaraynta qashinka ee wasakhda ah. Pyrolysis, nooc ka mid ah Wte, jawaabtu waa. Macmiilku wuxuu doonayaa inuu ogaado haddii tikniyoolajiyadda Pyrolysos loo isticmaali karo soo kabashada taayirrada iyo sida. Waxyaabaha soo socdaa waa waxa aan ka wada hadalnay macmiilka Jarmalka.

Sida loo dhiso xarun jilicsan oo taayir ah oo ku taal Jarmalka gudaha 3 Talaabooro?

Suuqa taayirrada ee Jarmalka waa mid aad u weyn oo la filayo inuu ku koraan suuliga 3.80% muddo 2024-2032. Oo leh sahay ku filan oo taayirrada xaashiyaha ah sida qalabka ceyriinka ah, Macaamiishayada Jarmalka ayaa xiiseynaya dejinta warshad taayirrada taayirrada ah. Waxay wax ka weydiiyeen faahfaahinta dejinta geedka si ay u bilaabaan meheradda maaddaama ay ka fiirsanayaan iyagoo adeegsanaya maareynta taayirrada taayirrada ah iyo mashaariicda dib-u-warshadaynta. Si looga jawaabo su'aalahooda ku saabsan Pyrolysis, Aynu ku bilowno seddex talaabo.

Diyaargarowga dhirta taayirrada taayirrada

Tallaabo qaadid 2 Si loo dhiso warshad taayirrada taayirrada ee Jarmalka

Tallaabo qaadid 3 Si loo dhiso xarun taayir ah oo taayir ah oo ku taal Jarmalka

Waa maxay wax soo saarka taayirrada taayirrada?

Sida loo doorto foornooyinka Pyrolysis ee loogu talagalay taayir pyrysis dhirta dhirta?

Kadib waxaan sii wadnaa inaan ka wada hadalno macmiilka Jarmalka. The client wants to set up a pyrolysis plant to recycle tyres and other rubber waste. They inquire which pyrolysis furnaces are best for their recycling plant.

Actually when choosing a tire pyrolysis furnace, it’s essential to consider different operating modes such as Dhuf-firid, Koob – continuous, iyo Fully continuous.

Waxqabadka Flonce iyo hufnaanta

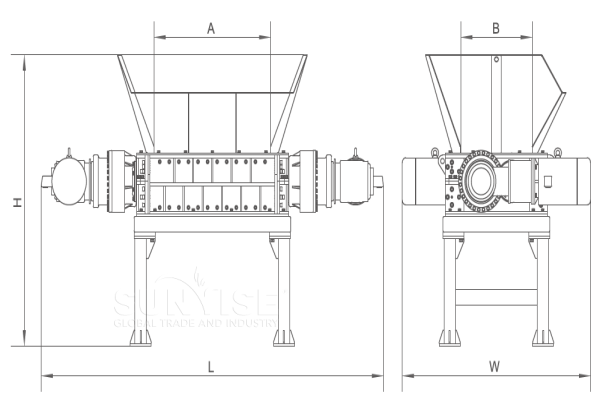

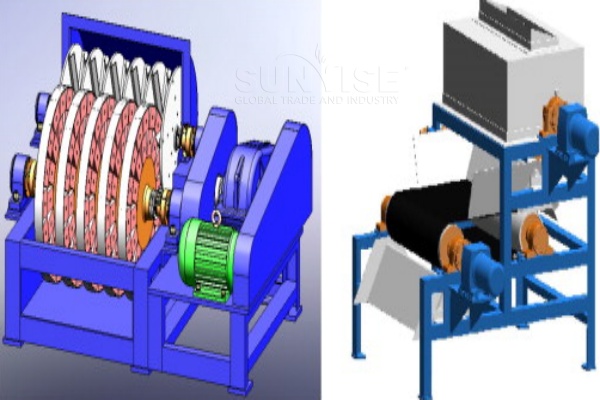

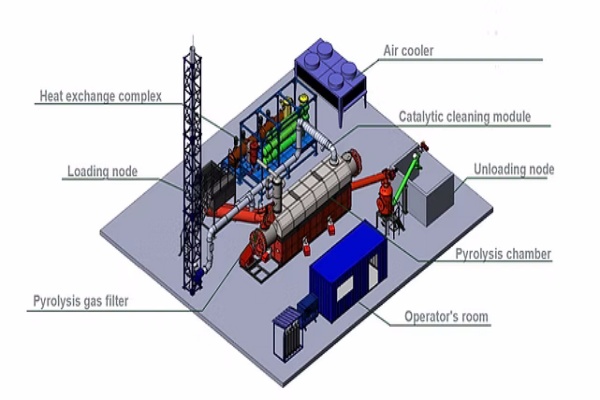

Qalabka dhirta dhirta ee Pyrolyssis

Mashiinka taayirrada

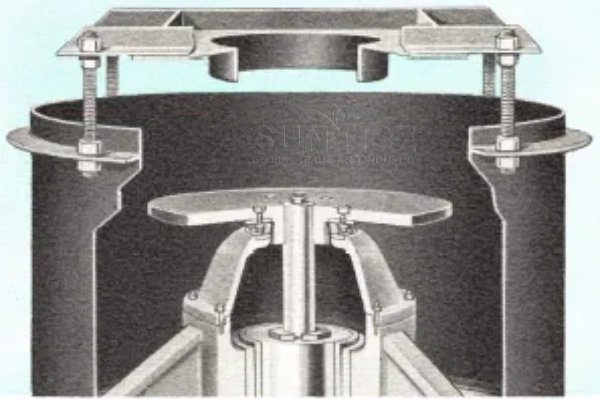

Cayayaanka ee Yushaunxin Pyrolus Prorysis foornada

| Item | Waste pyrolysis unit | ||

| Equipment type | Dhuf-firid | Semi-continuous | Fully continuous |

| Raw materials | Rubber tyres, barid-badee, oil sludge, coal tar, aluminium plastics, itc. | ||

| Structure form | Horizontal rotation | ||

| 24-hour capacity | 100 kg-20 tonnes | 10-20 tonnes | 15-50 tonnes |

| Oil yield From | 30-70 per cent | ||

| Operating pressure | Normal | ||

| Pyrolysis reactor material | Q245/345R, boiler plate, stainless steel | ||

| Thickness of pyrolysis reactor | 14, 16, 18, 20 mm | ||

| Speed of pyrolysis reactor | 0.4 rpm | ||

| Total power | ≤ 30KW | ||

| Cooling mode | Circulating water cooling | ||

| Condenser cooling area | 100 square metres | ||

| Type of transmission | Internal gearing | ||

| Culeys | Depending on size | ||

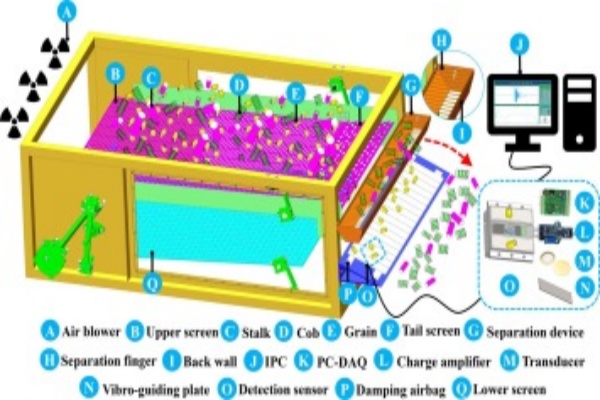

Celcelis ahaan dhalidda saliida ee qashinka qashinka qashinka ee ku saabsan dhirta lagu muujiyey quudinta

Intee in le'eg oo macaash ah ayaad ka sameyn kartaa taayir pyrysis dib u warshadaynta?

The client wants to invest in a tyre-recycling plant now. Sidaas darteed, they asked about the profit from tyre pyrolysis recycling. “We wanted to know how much money this recycling production line could make.” This is also a question that most customers are very concerned about. Actually this depends on many things.

Qiyaasta dhirtaada pyrolysis-ka

Qiimaha badeecada Pyrolysis iyo baahida suuqa

Ma jiraa wax tixraaca xalka ah ee taayirrada ee loo habeeyay?

oLet’s differentiate based on processing capacity. The following we’ll provide you with German waste tire pyrolysis recycling production line of different scales for reference. Customers can make adjustments as needed:

Yar TIRE Pyrolysis dib-u-warshadeynta khadka wax soo saarka (ku habboon bilaabida bilowga ama wax soo saarka tijaabada ah)

The daily processing volume of waste tires is about 1-2 tons, mainly producing rubber particles, some steel wires, iyo saliida pyrolysis.

Kahor Pyrolysis

Mashiinka Pyrolysis(ikhtiyaar ah)

Dhinacyada kale ee xalka Pyrolussis

Heer dhexe ah xalka wax soo saarka dib-u-warshadaynta (suuq goboleed)

The daily processing volume of waste tires is 5-10 tons, and high-quality rubber particles and high-quality carbon black are produced for tire retreading or high-end rubber production, and recycled steel wire is sold. The pyrolysis oil meets the industrial fuel standard and is partly used for self-use and partly sold.

Kahor Pyrolysis

Mashiinka Pyrolysis(ikhtiyaar ah)

Continuous tire pyrolysis furnace: It produces 1-2 tons of pyrolysis oil and 0.8-1.2 tons of carbon black per day, uses natural gas or biomass particles as fuel, has a thermal efficiency of more than 70%, and is equipped with waste heat recovery for drying and other links.

Dhinacyada kale ee xalka Pyrolussis

Qiyaasta ballaaran Qorshaha Waxsoosaarka Dib-u-warshadaynta ee Taayirrada (Kooxda warshadaha)

Daily processing of 20 tons or more of waste tires, large-scale production of high-quality rubber product raw materials, kaarboonka madow, and steel wire, and pyrolysis oil for park energy or external sales.

Qaadashada Qalabka kahor Pyrolysis

Pyrolysis iyo kuleylka kuleylka qoto dheer

High-efficiency large-scale pyrolysis furnace group: multiple continuous pyrolysis furnaces in parallel, daily output of 5-8 tons of pyrolysis oil and 3-5 tons of carbon black, advanced heat recovery and automatic control to ensure stable operation.

Carbon black modification and granulation production line: Deep modification and granulation of carbon black to meet the needs of tires and high-end rubber, with strong product competitiveness; pyrolysis oil refining device purification reaches the high-quality standard of fuel oil.

Dhinacyada kale ee xalka Pyrolussis

Maxaad u doorataa ysx sidii pyrolysis-kaaga pyrolysis-ka?

Maxay Aqoonsiyada Ma haysannaa?

At SUNRISE, CE iyo ISO 9001 certifications are just part of our offerings in this regard. We’ve got a whole slew of other certifications up our sleeve to meet diverse compliance and quality benchmarks as well.

Macmiilad Sawirro jawaab celin ah ee dhirta pyrolysis

Ugu dhambayntii, our German customers want to know how pyrolysis works in specific production case studies. This can help them decide if this technology is right for them. Let’s take a look at some great examples. Click here to know more.

YSX team can provide you not only the tire reycling solutions, but also e-waste disposal plan like batteries recycling solutions, circuit board recycling solutions, iyo solar panel reycling solutions. Feel free to contact us if you wanna start recycling business.

Nala soo xiriir