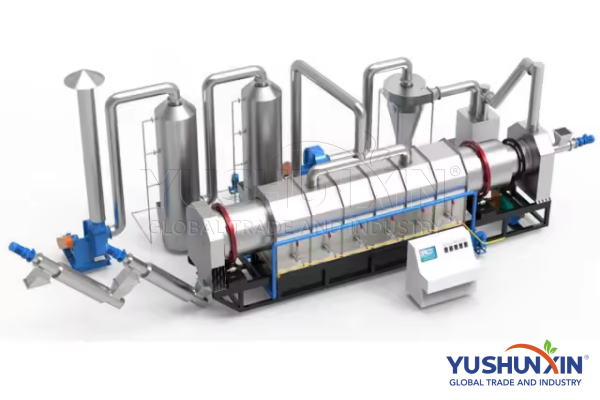

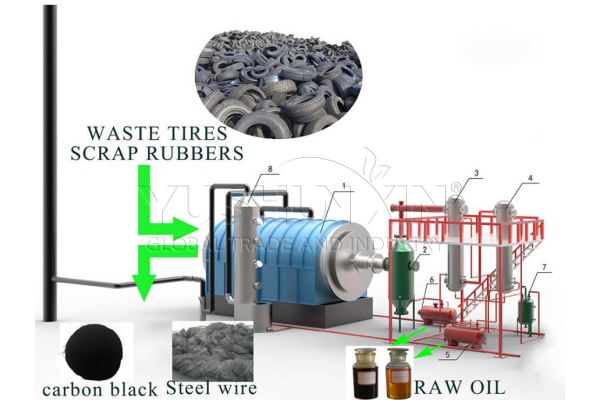

Závod Pyrolýzy v pneumatike odpadu účinne prevádza odpadové pneumatiky na cenné produkty, ako je pyrolýza olej, čierny, oceľový drôt, a horúci plyn prostredníctvom procesu pyrolýzy. Táto pokročilá technológia recyklácie sa zaoberá nielen rastúcim problémom znečistenia pneumatík, ale tiež vytvára vysoko výnosnú obchodnú príležitosť. Navyše, S rastúcim globálnym dopytom po ekologických riešeniach, Yushunxín Zariadenie na pyrolýzu odpadových pneumatík sa stalo ideálnou voľbou pre udržateľnú recykláciu pneumatík. Poďme preskúmať ďalšie podrobnosti o tomto výkonnom systéme recyklácie odpadových pneumatík.

Aký je pracovný proces pyrolýzy pneumatiky odpadu?

Pneumatiky na vkladanie pneumatík do pneumatiky pyrolýzy

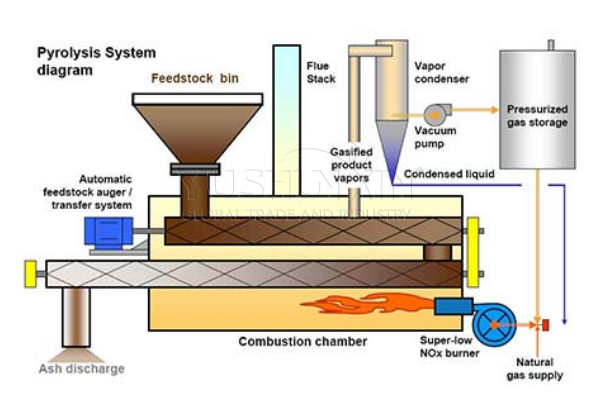

Začnite prípravou pneumatík odpadu do reaktora pneumatického pyrolýzového stroja prostredníctvom automatického podávača. Uistite sa, že naplníte iba dve tretiny kapacity reaktora, aby ste zabezpečili plynulé a efektívne otáčanie počas spracovania. Akonáhle sú pneumatiky v, Bezpečne zatvorte kŕmne dvere, aby ste začali s procesom konverzie oleja na konverziu oleja.

Zohrejte reaktor a začnite separáciu ropného plynu

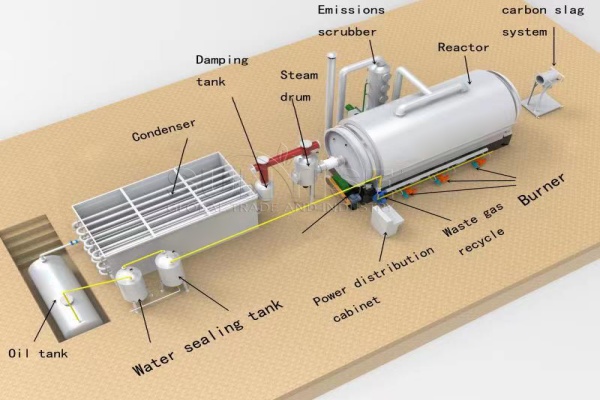

Zohrejte reaktor pomocou dostupných palív, ako je uhlie, drevo, zemný plyn, alebo pyrolýza oleja z predchádzajúceho cyklu. Keď teplota dosiahne 100 ° C, Začína sa tvoriť ropa a plyn. Na dosiahnutie najvyššieho výnosu oleja, Udržujte teplotu reaktora medzi 250 ° C a 280 ° C. Systém rozdeľuje v potrubí ťažký olejový plyn a po skvapalnení ho nasmeruje do ťažkej ropnej nádrže. Medzitým, cez kondenzátor pyrolýzy oleja prechádzajú ľahšie oleja, premeňte na tekutinu, a sú uložené. Nepraviteľné plyny sa filtrujú a recyklujú sa späť do pece na výrobu tepla, Zlepšenie palivovej účinnosti.

Ochladzujte reaktor a obnovte

Po dokončení výroby ropy, Nechajte reaktor prirodzene vychladnúť. Keď teplota klesne o 40 ° C, Stroj automaticky vypustí uhlíkovú čiernu do zberného systému. Ak spracováva celé pneumatiky, Počkajte, kým teplota klesne pod 50 ° C a potom pomocou mechanického háku na extrahovanie oceľových vodičov. Tento krok dokončí proces regenerácie uhlíka.

Resetujte na ďalší cyklus pyrolýzy

Pred spustením ďalšej dávky, potvrdiť, že všetky materiály boli odstránené, reaktor sa dostatočne ochladil, a všetky bezpečnostné kontroly sú dokončené. Táto príprava je kľúčová na udržanie dlhodobého výkonu zariadenia na pyrolýzu pneumatík a na zabezpečenie konzistentnej konverzie odpadovej pneumatiky na olej.

Aké je využitie finálneho produktu pyrolýzneho zariadenia na odpadové pneumatiky?

Závod na pyrolýzu odpadových pneumatík sa stal ziskovým a ekologickým riešenie pre recykláciu pneumatík. Tento proces nielen znižuje znečistenie životného prostredia, ale vytvára aj množstvo cenných konečných produktov, ktoré možno široko použiť v rôznych odvetviach. Tu je rozpis štyroch hlavných produktov vytvorených počas procesu pyrolýzy a ich príslušných trhových aplikácií:

Proces pyrolýzy extrahuje pyrolýzny olej, ktorý obsahuje užitočné zlúčeniny ako napr benzén, toluén, xylén, styrén, dimér pentén, trimetylbenzén, a tetrametylbenzén. Tieto látky sa bežne používajú ako chemické suroviny v rôznych priemyselných odvetviach.

Navyše, tento olej slúži ako náhrada nafty v oceliarňach, cementárne, kotlové systémy, a generátory ťažkého oleja. S ďalšou destiláciou, pyrolýzny olej možno rafinovať na motorovú naftu, čo z neho robí vysoko dopytovaný energetický produkt v priemyselnom aj dopravnom sektore.

Proces tiež produkuje sadze, ktorý sa primárne používa ako spevňujúce plnivo pri výrobe nízkokvalitnej gumy, vrátane výroby pneumatík a gumených podrážok. Navyše, sadze pôsobia ako pigment pre atramenty a farby.

Vo svojej surovej podobe, možno ho priamo použiť ako tuhé palivo. Však, s ďalším mletím a rafináciou, dá sa upgradovať na aktívne uhlie, otváranie možností vo filtrácii, čistenie, a trhy s chemickou adsorpciou, kde dopyt stále rastie.

Odpadové pneumatiky obsahujú drôt z pružinovej ocele, ktorý zostáva nedotknutý počas pyrolýzy v dôsledku nízkej teploty, prostredie bez kyslíka. To zaisťuje zachovanie mechanických vlastností ocele.

Po rozchode, túto vysokokvalitnú oceľ možno ďalej predať spracovateľskému priemyslu alebo priemyslu pretavovania, ponúka lukratívny výnos a podporuje obehové hospodárstvo v oblasti hutníctva.

Počas pyrolýzy, vzniká značné množstvo horľavého plynu. Skôr ako vypustiť, závod tento plyn recykluje ako vnútorný zdroj paliva na vykurovanie samotného reaktora. Tento uzavretý systém znižuje prevádzkové náklady a minimalizuje škodlivé emisie, zlepšenie energetickej účinnosti a environmentálneho správania.

Cenové riešenie závodu na pyrolýzu odpadových pneumatík

Hľadáte cenovo dostupné a efektívne zariadenie na pyrolýzu odpadových pneumatík? Či už ste malý recyklátor alebo veľký investor, výber správnej kapacity a cenového rozpätia je rozhodujúci pre návratnosť investícií a dlhodobú stabilitu.

| Kapacita (Tony/deň) | Typ | Odhadovaná cena (USD) | Odporúčané pre |

| 1-3 TPD | Dávka | $30,000 - $60,000 | Malé startupy |

| 5-10 TPD | Polokontinuálne | $65,000 - $120,000 | Stredne veľké rastliny, flexibilné ops |

| 12-20+ TPD | Plne súvislá čiara | $130,000 - $300,000+ | Priemyselná kvalita, vo veľkom meradle |

Tip: Dajte si pozor na príliš lacné ponuky, ktorým chýbajú certifikácie CE/ISO alebo správne systémy kontroly emisií.

Aby sme vám ešte viac pomohli poznať zisk zariadenia na pyrolýzu odpadových pneumatík, môžeme vám poskytnúť analýzu zisku závodu na pyrolýzu odpadových pneumatík 12T/D.

| Prevádzkové náklady / deň | |

| Odpadové pneumatiky | 12T*73USD/T=876USD |

| Vykurovacie palivo (Stačí si vybrať jednu z možností) |

1)Uhlie: 0.4T*58USD/T=23USD 2)Vykurovací olej: 0.4T*364USD/T=146USD 3) Diesel: 0.3T*582USD/T=175USD 4)Zemný plyn: 150M3*0,33USD/M3=4,9USD |

| Spotreba energie | 15Kw/h |

| Spotreba vody | Voda je určená na cirkuláciu, žiadna spotreba |

| Požadovaní pracovníci | 3 pracovníkov za zmenu * 22USD = 65 USD |

| príjem / deň | |

| Palivový olej | 4.5T*364USD/T=1637USD |

| Sadze | 1) priamy predaj, 3T*73USD/T=218USD 2)brúsenie, 3T*291USD/T=873USD |

| Oceľový drôt | 1.5T*116USD/T=175USD |

| Denný zisk (Používajte vykurovací olej na vykurovanie a predávajte sadze priamo) |

1302USD/deň |

Čo viac chcú výrobcovia vedieť o zariadení na pyrolýzu odpadových pneumatík?

O pyrolýze odpadových pneumatík, možno by ste chceli vedieť veľa ďalších vecí. Od našich zákazníkov sa bežne žiadajú niektoré položky- recyklátorov odpadových pneumatík pre vašu referenciu. Ak potrebujete viac informácií o pyrolýze pneumatík a strojoch, vitajte, aby ste nás okamžite požiadali.

Ako výrobca zariadenia na pyrolýzu odpadových pneumatík s 10 roky bohatých skúseností, YUSHUNXIN môže nielen poskytnúť vysokokvalitné zariadenie na pyrolýzu odpadových pneumatík, ale tiež môžete nakonfigurovať zariadenie na pyrolýzu odpadových pneumatík podľa vašej konkrétnej situácie, aby vám pomohlo zariadiť harmonogram projektu. A ak potrebujete linku na drvenie a separáciu odpadových pneumatík, môžeme ponúknuť aj pre vás. Kontaktujte nás teraz a získajte bezplatnú cenovú ponuku na zariadenie na pyrolýzu odpadových pneumatík.

Kontaktujte nás