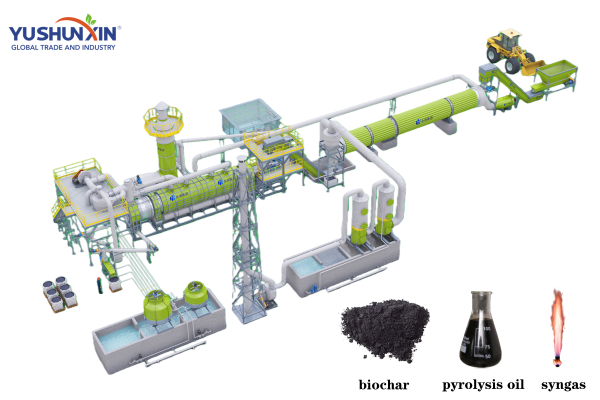

Sludge di desperdicio no ta djis un problema di deshaci mas—e ta un fuente scondi di recursonan valioso. Plantanan di pirolisis moderno por kombertí lodo efisientemente den zeta di balor haltu, gas, e produktonan di karbon ., converti desperdicio den ganashi .. Si ta pa industrial, Munisipal, òf aplikashonnan kímiko ., e plantanan aki ta ofrece no solamente economisacion di gasto y cumplimento regulatorio pero tambe generacion di energia renobabel ., yudando negoshinan maximalisa entrada mientras ta keda eco-friendly .. Pero con pa trata lodo di desperdicio .? Nos por proveé bo algun solushon pa bo eskoho.

Kico Ta e Proceso di Pirolisis di Sludge Desperdicio?

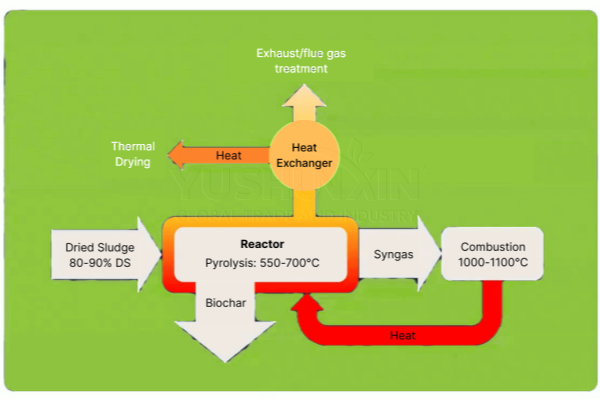

E proseso di pirolisis di lodo di desperdisio ta kombertí lodo di humedat den kombustibel ., produktonan di karbon, e gas limpi .. Proper pre-treatment and precise control of drying and pyrolysis conditions are essential to ensure efficiency and product quality.

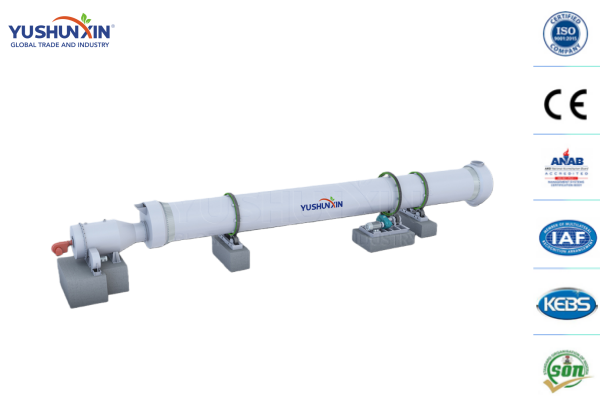

The first step removes excess water from sludge. The sludge first enters a rotary drum dewatering machine to remove excess water. The drum rotates continuously while internal screens and pressure separate solids from liquids. This process reduces moisture from 80% to around 60%, creating a stable feed for the next stage. Because the machine operates continuously, it handles large volumes without interruption. Adjustable drum speed and pressure allow operators to optimize performance based on sludge thickness. Effective dehydration lowers energy consumption in the drying stage and prevents material clumping.

After dewatering, the sludge moves into a rotary drum dryer for deeper moisture reduction. The dryer uses 120–150°C hot air to evaporate water while the rotating drum lifts, scatters, and heats the material evenly. Residence time typically ranges from 20–40 minutes, depending on moisture content. This process reduces water levels from 60% to below 10%, preparing the sludge for efficient pyrolysis. Stable airflow, controlled temperature, and continuous feeding ensure uniform drying, prevent overheating, and maintain the quality of organic components.

Finally, The dried sludge enters a sealed pyrolysis reactor and heats up to 400–600°C in an oxygen-free environment. At this temperature, organic compounds break down quickly into oil vapor, syngas, e karbon sólido .. E lodo ta keda den e reaktor pa 30–60 minüt ., permitiendo full rancamento y volatilisacion .. Keintamentu indirecto i bladenan di spiral interno ta sòru pa asta distribushon di temperatura .. Parti di e syngas ta bolbe como combustibel di kimador ., redusí uso di energia, mientras cu e restante gas y vapor di azeta ta pasa pa e condensador pa recuperacion ..

Loke Produktonan Valioso Bo Por Haña di Pyrolisis di Sludge Desperdisio?

Pirolisis di sludge di desperdisio ta krea vários produkto komersial. Cada produccion tin balor economico cla ., permitiendo negoshinan recupera gastonan y genera ganashi mientras ta mantene cumplimento ambiental ..

How Quickly Can You Recover Your Investment from a Waste Sludge Pyrolysis Plant?

The payback period of a waste sludge pyrolysis plant depends on plant capacity, product value, and daily operating costs. With stable sludge supply and consistent product sales, hopi invershonista ta rekuperá nan kapital inisial mas lihé ku solushonnan tradishonal di tratamentu di desperdisio ..

Den total, operadornan por gana $300–900 pa ton di lodo trata ., dependiendo di mercadonan local .. Redusí disposishon i gastunan di energia ta aselerá ROI i hasi pirolisis un invershon a largu plaso rentabel.

Kon un Desperdisio di Pirolisis di Pirolisis ta kumpli ku Normanan di Emishon?

Kumplimentu di regulashon ta krítiko pa pirolisis di lodo. Mashinnan moderno ta adoptá sistemanan di limpiesa i kòntròl di gas pa redusí kontaminantenan ., sigurá ku e normanan di emishon ta wòrdu kumplí sin efisiensia di proseso di komprometé.

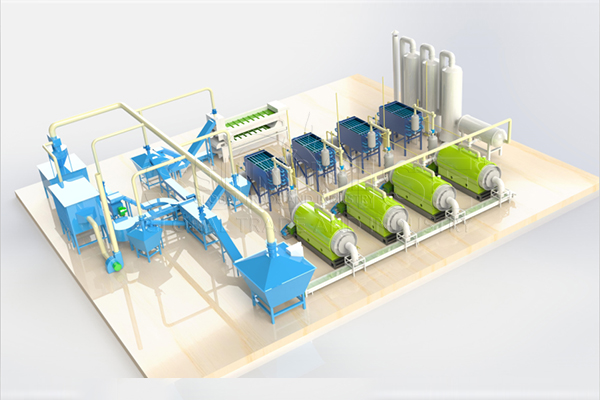

Waste Sludge Treatment Solutions for Manufacturing, Mining & Camponan di Zeta

Different industries produce sludge with varying compositions. Pyrolysis technology adapts to these variations, providing effective solutions for manufacturing, mining, e operacionnan di veld di petroleo mientras ta converti desperdicio den recursonan valioso ..

Plantanan di fabricacion ta genera lodo di procesamento kimico ., tintahe di tekstil, produkshon di papel, e prosesamentu di kuminda .. E lodo aki hopi biaha ta contene organiconan ., fibranan, zetanan, e residuonan kímiko .. Pirolisis ta stabilisá e materialnan aki i ta kombertí nan den energia usabel .. E proseso ta redusí e volúmen di desperdisio ku mas ku 60–70% ., ku ta baha e gastunan di deshasimentu signifikantemente .. Fabrikanan por reusá zeta di pirolisis den boiler òf bende esaki komo un kombustibel industrial .. Mientras, char por sirbi komo un kombustibel sólido òf wòrdu agregá na materialnan di konstrukshon .. Esaki ta crea un sistema di maneho di desperdicio circular y sostenibel ..

Operashonnan di mineria ta produsí lodo ku ta kontené mineralnan fini ., residuonan orgániko, metalnan pisá, e kimiconan di flotacion .. E metodonan di deshacimento tradicional ta costa hopi y ta crea riesgonan ambiental a largo plaso .. Pirolisis ta ofresé un alternativa mas limpi dor di kibra komposishonnan orgániko i redusí toksisidat di lodo. E proseso ta generá singas pa keintamentu riba e sitio i char pa uso metalúrgiko .. Char pirolisa tambe por asisti den remediacion di tera rond di sitionan di mineria pasobra e ta stabilisa metalnan pisa .. Ku redusí volúmen di desperdisio i energia rekuperá ., kompanianan di mineria ta mehorá tantu kumplimentu ambiental komo efisiensia operashonal ..

Sludge di zeta di zeta ta kontené hidrokarburonan ., fluidonan di boramentu, parafina, e partikulonan sólido .. E tipo di lodo aki ta representa riesgonan ambiental y maneho halto .. Pirolisis ta recupera 15–25% di azeta manera crudo ., ku por wòrdu reusá den operashonnan di boramentu òf refiná pa kombustibel industrial .. Syngas ta sostené e sistema di keintamentu di e mata, redusí konsumo di energia. E restante karbon sólido ta bira un safe ., produkto di toksisidat abou adekuá pa konstrukshon òf meskla di kombustibel .. Debí ku pirolisis ta eliminá hidrokarburonan dañino i ta minimalisá masa di desperdisio ., kompanianan di petroli ta logra kumplimentu regulatorio i baha gastunan di tratamentu miéntras ta rekuperá rekursonan di energia balioso ..

Ademas di, solucion di pirolisis di desperdicio, tambe nos por proveé bo ku hopi otro sistema di deshací. Manera planta di pirolisis, liña di pyrolisis di plèstik di desperdisio, etc. Bon bini pa tuma kontakto ku nos pa bo mes plan di resiklahe di e-waste.

Tuma kontakto ku Nos