Segun ku polushon di plèstik mundial ta sigui intensifiká ., hopi pais i industria ta buskando solushonnan di resiklahe mas efisiente .. Metodonan di reciclahe mecanico tradicional hopi biaha ta lucha cu asuntonan manera degradacion di plastic ., kontaminashon, e kompleksidat di sorteo di materialnan miksto .. E limitashonnan aki ta redusí efisiensia di resiklahe i kalidat di produkto .. Den kontesta ., teknologia di pirolisis a surgi komo un alternativa prometedor .. E método di resiklahe kímiko avansá aki ta pèrmití industrianan pa deskomponé plèstiknan di desperdisio termikamente den un temperatura haltu, ambiente liber di oksígeno. Pa medio di e proceso aki ., kompanianan por kombertí desperdisio di plèstik den produktonan di balor haltu manera fuel oil ., gas kombustibel, e karbon pretu .. Dor di ofresé un manera mas limpi i mas efisiente pa utilidat desperdisio di plèstik ., pirolisis ta duna un solushon sostenibel pa rekuperashon di rekurso i protekshon di medio ambiente ..

Ki tipo di plèstik ta adekuá pa resiklahe di pirolisis .?

Algun plastic ampliamente uza ta ofrece un potencial excelente pa produccion di fuel oil pa medio di pirolisis debi na nan rendimento halto di azeta .. Komprondementu di e karakterístikanan i aplikashonnan típiko di e plèstiknan aki por yuda e resikladónan identifiká materialnan balioso.

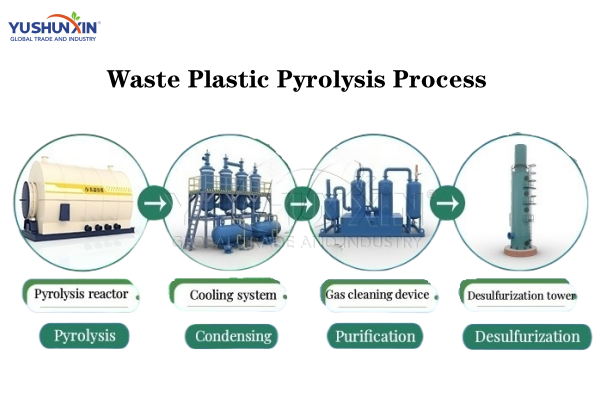

Kiko ta e proseso di pyrolisis di plèstik di desperdisio?

Promé ku e proseso di pirolisis kuminsá, pretratamentu korekto di desperdisio di plèstik ta esensial pa mehorá efisiensia i kalidat di produkto ..

- Klasifikashon i screening .: Operadornan mester sorteá promé plèstik di desperdisio pa tipo .. E paso aki ta kita materialnan manera PVC i PET ku no ta adekuá pa pirolisis i ta yuda redusí e riesgo di emishon òf kontaminashon dañino ..

- Limpiesa i seku: Porkeria, humedat, e impuresanan di superficie mester wordo elimina pa evita reaccionnan kimico indesea durante calefaccion ..

- Aplastamentu i pulverisashon .: Despues ta aplasta plastic den uniform ., tamañonan di partikulo manehabel pa sigurá asta keintamentu i mihó kombershon durante pirolisis ..

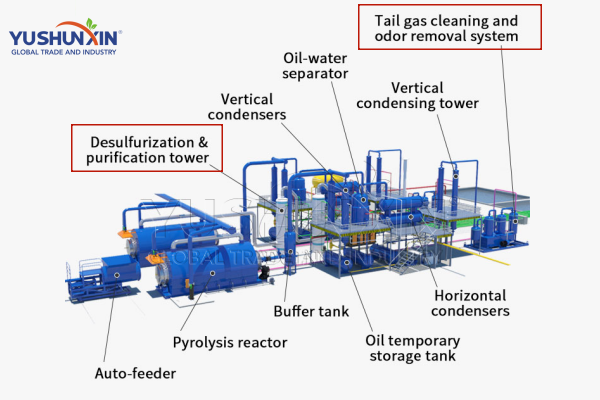

E núkleo di e proseso di resiklahe ta sinta den e deskomposishon termal di polímeronan di plèstik bou di kondishonnan kontrolá.

- deskomposishon di kalentamentu: Den un ambiente liber di oksígeno òf ku tiki oksigeno ., plasticnan pretrata ta wordo calenta gradualmente na temperaturanan entre 300°C y 900°C .. Y esaki ta pone cu e cadenanan di polimer largo ta kibra den moleculenan di hidrocarburo mas chikito ..

- Kontrol di reakshon: Por ahusta e temperatura ., tasa di keintamentu, e tempu di retenshon ., operadónan por optimalisá tantu e kantidat komo kalidat di e produktonan di pirolisis final ., inkluso oil di fuel i pretu di karbon ..

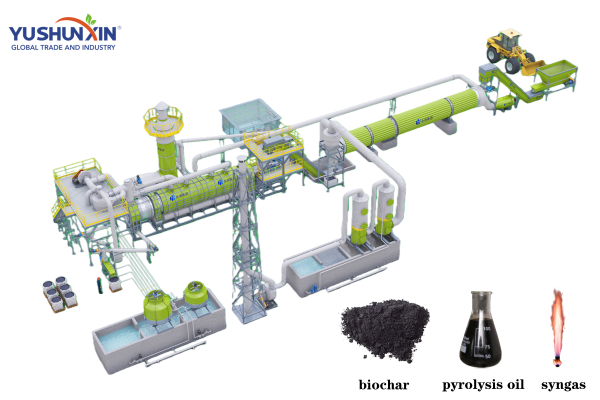

After decomposition, the pyrolysis system shifts focus to condensing and separating useful products from the gas stream.

- Gas condensation: The hot vapor is cooled using a condensation system to recover high-value liquid fuel oil.

- Carbon black collection: Solid residues from the reaction are mainly carbon black, which can be repurposed in the manufacturing of rubber, plèstik, pigment, or ink.

- Combustible gas utilization: The remaining uncondensed gas is flammable and can be recycled back into the heating system to reduce external energy usage.

Sustainability is a priority, and effective environmental controls are integrated throughout the pyrolysis system.

- Gas purification: Harmful components in the exhaust gases are filtered through deacidification, dust removal, and adsorption units to meet environmental emission standards.

- Wastewater treatment: Any wastewater generated is properly treated using filtration or chemical processes before discharge, preventing soil or water pollution.

Technical parameters of plastic pyrolysis plant

| Models | Batch Type | Semi-Continuous Type | Continuous Type |

| Unit Capacity | 5-20 Tons/day | 15-25 Tons/day | 20-70 Tons/day |

| Feedstock Size | ≤1600mm | ≤100mm | ≤80mm |

| Feedstock Pretreatment | Need to be pre-processed by shredder or grinder to the appropriate size | Need to be pre-processed by shredder or grinder to the appropriate size | |

| PLC | Optional | Optional | Equipped with |

| Reactor Cooling Time | 3-12 hours | 3-5 hours | 0 |

| Poder | 12-25 kW/h | 15-30 kW/h | 50 kW/h |

| Maintenance Period | 1 day | 7-10 dianan | 45-60 dianan |

What is the waste plastic pyrolysis plant price?

Generally, the price of the system of recycling waste plastic is not fixed. Because it depends on your capacity, equipment types, project design, etc. The plastic pyrolysis system costs range from $80,000 pa $400,000.

$80,000-$250,000 basic plastic pyrolysis system

For $80,000-$250,000 budget, you can choose to only buy a basic plastic pyrolysis system, which consists of feedstock pretreatment system (mas skerfé, dryer), reaktor di pirolisis (batch type), condensation system (cooling tower, oil-water separator), oil storage tank, gas recycling and purification system, basic emission treatment (dust collector, water spray) and control cabinet (semi-automatic).

$180,000-$300,000 upgrading design of plastic pyrolysis plant

With $180,000-$300,000, we can offer you an upgrading design of automatic feeding system, continuous pyrolysis reactor, multi-stage condensing system, oil-gas separator & storage units, dedusting system (spray tower + activated carbon), cooling tower, full control system (PLC, sensors, remote control), with an output of 15-25 t/d.

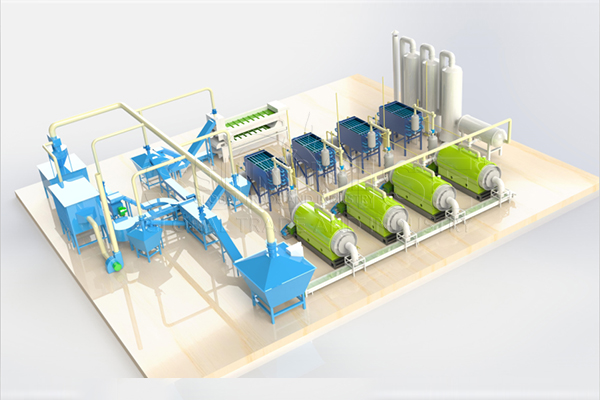

$300,000 pa $400,000 continuous waste plastic pyrolysis plant

With cost of $300,000 pa $400,000 or more, you can setup a waste plastic pyrolysis plant with the whole process. Including fully continuous feeding & discharging system, high-efficiency pyrolysis reactor with insulation, advanced oil-gas condensation & separation unit, gas purification and full recycling system, complete flue gas treatment system (spray tower, neutralizer, activated carbon), heat recovery system, intelligent control room (SCADA/PLC). The largest capacity can reach recycle 20-70 tons of waste plastic per day.

Can we recycle something from other waste? The answer is yes. As a professional e-waste bussiness provider, there are also many other waste recycling systems for you. Manera waste tyre recycling plan, planta di pirolisis, solar panel disposal line, etc. If you have any other requirements, welcome to contact us for your own e-waste recycling line now!

Tuma kontakto ku Nos