Sicut novi industria electrica vehiculum (Nev) Market continues ad expand exponentially, Et exitus de vehiculum redivivus emersit quasi crucial aspect ad sustineri progressionem de industria. A 2025, Nos anticipate quod redivivus non solum esse necessitate environmental tutela sed etiam potentiale fons valuable opibus et oeconomica occasiones. Cum augendae numerus finem-of-vitae NEVS, Rerum RECYCLING modi et infrastructure erit essentialis tractamus growing volumine abdicavit vehicles.

Vos can redivivus quod partes novae industria vehicles?

Recyclable items in novam industria electrica vehiculum (Nev) superficies

Fenestram speculum NEVIS potest non aluminis et recycled. Hoc processum involvit solveret speculum in parvis pieces, quae potest igitur et liquefactum et reformat in novum speculum products, reducing opus virginem rudis materiae.

Insuper, et car corpus plastics, quae late usus est in modern vehiculum vestibulum pro suae radicem et durabile proprietatibus, potest oppressi et processionaliter ad cedere oeconomica beneficia. Hi REDIVIVUS plastics potest esse in variis industries, Ut productio plastic pellets ad vestibulum novum plastic components vel in constructione industria non-structural applications.

Recyclable materiae intra industria electrica automobiles

Lithium batteries in nova industria altilium electrica vehicles (BEV) sunt a significant fontem gemmas metalla. Haec gravida quae elementa sicut Lithium, cobalt, nickel, et manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Lithium batteries in nova industria altilium electrica vehicles (BEV) sunt a significant fontem gemmas metalla. Haec gravida quae elementa sicut Lithium, cobalt, nickel, et manganese, which are in high demand for the production of new batteries. Through advanced recycling techniques, these precious metals can be recovered and reused, reducing the reliance on mining and the associated environmental impacts.

Quod machinis potest redivivus valuable materiae in novam industria Medici

When it comes to recycling the car shells of new energy EVs, heavy-duty shredding machines are essential. These shredders can handle the large and sturdy metal structures. Pro exemplo, hydraulic crushers with a powerful motor can exert high pressure to break down the car bodies into smaller pieces. They usually have a large crushing chamber and adjustable jaws to accommodate different sizes of car parts. The power of such crushers can range from 50 kW to 150 KW, enabling them to efficiently process the thick metal sheets of the car shells.

For the recycling of window glass, specialized crushers are required. These crushers are often equipped with toughened blades and a vibrating feeder system. The blades are made of high-quality alloy to withstand the hardness of the glass. The vibrating feeder ensures a continuous and even supply of glass pieces to the crushing area. Some advanced glass crushers can achieve a crushing size as small as 1 - 5 mm, which is crucial for further processing and separation of the glass components. The power consumption of these crushers is relatively lower compared to those for car bodies, typically around 10 kW to 30 KW.

Circuit boards in new energy EVs contain valuable metals and components. Crushers designed for circuit boards need to be more precise and gentle to avoid damaging the precious materials. Solent uti compositum mechanica tondentes et impulsum copiis. Et dentes et dentibus scutulis et controversiam et controversiam et contraciendo in circuitu tabulas in parva fragmenta in conservando integritatem metalla et semiconductors. Power horum vulgo in range 20 kW to 50 KW.

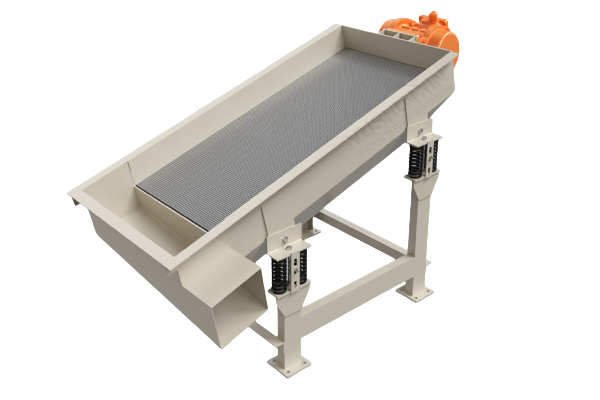

Tristis screens Cum alia Mesh magnitudinum sunt communiter usus. Haec screens potest separare contrita materiae secundum particula magnitudine. Pro exemplo, A pulsum screen cum mesh magnitudinem 2 - 10 mm potest efficaciter excutere de aluminium particulas ex non-metallic obruta. In protegendo efficientiam est crucial ut puritatem recuperavit metallum elementa. Nostri protegendo machinis instructa cum intelligentes imperium systems ad adjust in vibrationem frequency et amplitudine, optimizing the separation process.

Magnetic vibrating screens are widely used for separating metal elements. These screens utilize the magnetic properties of metals to attract and separate them from the non-metallic materials. They consist of a vibrating deck with built-in magnets and a variable-frequency drive system. The magnetic field strength can be adjusted according to the type and size of the metal particles to be recovered. Pro exemplo, for small metal fragments, a magnetic field strength of 2000 - 3000 Gauss is sufficient, while larger pieces may require a stronger field of 4000 - 5000 Gauss. The vibrating motion helps to move the materials along the screen surface, allowing the metal particles to be captured by the magnets and diverted to a separate collection chute. Insuper, our screen mesh size can be customized, typically vndique a 0.5 mm to 5 mm, to further refine the separation process and ensure the purity of the recovered metal elements.

Conclusio, the recycling of valuable materials in new energy EVs requires a combination of specialized recycling machines, each tailored to the specific characteristics of the materials being recycled. If you are an enterprise or individual interested in delving deeper into the field of new energy vehicle parts recycling, or if you have any questions regarding the selection of recycling equipment, contact us please. Our team is here to assist you.

Quam ut ut in solitudinem currus redivivus processus est pollutio, liberum

By implementing these pollution prevention measures, you can ensure that the waste car recycling process is environmentally friendly. We specialize in providing top-notch e-waste recycling solutions including dust removal. You can reach out to us via our contact form. We look forward to helping you enhance the environmental performance of your e-waste recycling business through our high-quality dust removal equipment.

Quomodo Recycling Novum Energy vehiculum partibus adducam vobis prodest?

In 2025, the recycling of new energy electric vehicle parts offers great economic promise. Advanced recycling technologies help unlock the value of discarded vehicles.

We manufacture professional recycling equipment with Ce et Iso certificaciones. Our offerings include lithium – battery recycling machines, solar panel recycling equipment, circuit – board recycling lines, et tire pyrolysis production line equipment.

If you’re interested in the new energy EV recycling business and unsure about equipment choices, contact us without hesitation.

Contact Us