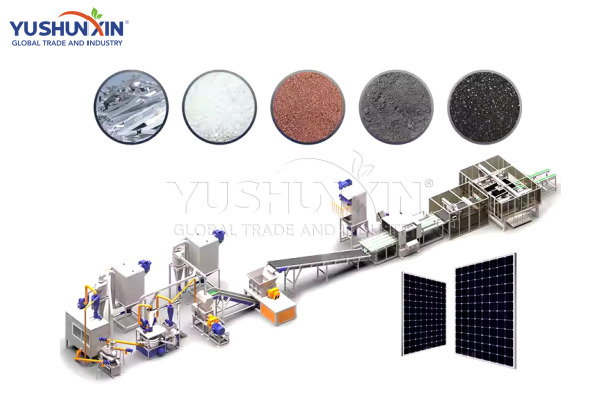

ಮಾರ್ಚ್ 16 ರಂದು 2025, ಭಾರತದ ಗ್ರಾಹಕರೊಬ್ಬರು ವಿಚಾರಿಸಿದರು ಸೌರ ಫಲಕಗಳು ಮರುಬಳಕೆ ಸ್ಥಾವರ ಜೋಡಿಸು. ಅವರು ಸೌರ ಫಲಕಗಳ ಮರುಬಳಕೆ ಘಟಕವನ್ನು ಸ್ಥಾಪಿಸಲು ಯೋಜಿಸುತ್ತಿದ್ದರು ಮತ್ತು ಪ್ರಸ್ತುತ ವಿಶ್ವಾಸಾರ್ಹ ತಂತ್ರಜ್ಞಾನ ಪೂರೈಕೆದಾರರು ಮತ್ತು ಸಲಕರಣೆಗಳ ತಯಾರಕರನ್ನು ಮೌಲ್ಯಮಾಪನ ಮಾಡುವ ಪ್ರಕ್ರಿಯೆಯಲ್ಲಿದ್ದರು. ಮತ್ತು ಸ್ಥಾವರವನ್ನು ಸ್ಥಾಪಿಸಲು ನಾವು ಅವರಿಗೆ ಉತ್ತಮ ಉದ್ಧರಣ ಮತ್ತು ವಿವರವಾದ ಪ್ರಸ್ತಾಪವನ್ನು ಒದಗಿಸಬೇಕೆಂದು ಅವರು ಬಯಸಿದ್ದರು. ಇದಕ್ಕಾಗಿ, ದ್ಯುತಿವಿದ್ಯುಜ್ಜನಕ ಫಲಕಗಳ ವಿಲೇವಾರಿ ರೇಖೆಯನ್ನು ನಾವು ಶಿಫಾರಸು ಮಾಡುತ್ತೇವೆ 1 ಟಿ/ಎಚ್ ಸಾಮರ್ಥ್ಯ. ಈ ಸಂದರ್ಭದಲ್ಲಿ ನಮ್ಮ ಸಂವಹನದ ನಿರ್ದಿಷ್ಟ ವಿವರಗಳು ಈ ಕೆಳಗಿನಂತಿವೆ:

1000 ಕೆಜಿ/ಗಂ ಸೌರ ಫಲಕಗಳ ಮರುಬಳಕೆ ಸಸ್ಯದ ವಿನ್ಯಾಸ ಏನು?

ಭಾರತೀಯ ಸೌರ ಫಲಕಗಳ ಮರುಬಳಕೆಗೆ ಕಡಿಮೆ ವೆಚ್ಚದ ಪರಿಹಾರದ ಅಗತ್ಯವಿದೆ. ಹೀಗೆ, ಸ್ಟ್ಯಾಂಡರ್ಡ್ 1000 ಕೆಜಿ/ಗಂ ಸೌರ ಫಲಕಗಳ ವಿನ್ಯಾಸ ಮರುಬಳಕೆ ಘಟಕವು ಯಾಂತ್ರಿಕ ದ್ಯುತಿವಿದ್ಯುಜ್ಜನಕ ಫಲಕ ಮರುಬಳಕೆ ವ್ಯವಸ್ಥೆಯನ್ನು ಅಳವಡಿಸಿಕೊಳ್ಳುತ್ತದೆ. ಮುಖ್ಯ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಪ್ರಕ್ರಿಯೆಯ ಹರಿವು ಇರುತ್ತದೆ 6 ಭಾಗ. ಸೌರ ಫಲಕಗಳು ಕಿತ್ತುಹಾಕುತ್ತವೆ. ಈ ಸೆಟಪ್ನಲ್ಲಿ,

1000 ಕೆಜಿ/ಗಂ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಸ್ಥಾವರ ವೆಚ್ಚ ವಿಶ್ಲೇಷಣೆ ಪ್ರಾರಂಭವಾಗುತ್ತದೆ

ಆಗ, ಈ ಗ್ರಾಹಕರು ಈ ಯಾಂತ್ರಿಕ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಸ್ಥಾವರದ ಬೆಲೆಯ ಬಗ್ಗೆ ಕೇಳಿದರು. ಸ್ಥಾಪಿಸಲಾಗುತ್ತಿದೆ 1000 ಕೆಜಿ/ಎಚ್ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಸೌಲಭ್ಯಕ್ಕೆ ಸಲಕರಣೆಗಳ ಹೂಡಿಕೆ ಮಾತ್ರವಲ್ಲದೆ ಅನುಸ್ಥಾಪನೆಯಂತಹ ವೆಚ್ಚಗಳನ್ನು ಸಹ ಬೆಂಬಲಿಸುತ್ತದೆ, ನಿಯೋಜನೆ, ತರಬೇತಿ, ಮತ್ತು ಕಾರ್ಯಾಚರಣೆಯ ವೆಚ್ಚಗಳು. ಪ್ರಮುಖ ವೆಚ್ಚದ ಘಟಕಗಳ ಸ್ಥಗಿತವನ್ನು ಕೆಳಗೆ ನೀಡಲಾಗಿದೆ.

ಉಪಕರಣಗಳು ಮತ್ತು ಸ್ಥಾಪನಾ ವೆಚ್ಚಗಳು

ಮುಖ್ಯ ಸಲಕರಣೆಗಳ ಪ್ಯಾಕೇಜ್, ಕಿತ್ತುಹಾಕುವುದು ಸೇರಿದಂತೆ, ಪುಡಿಮಾಡುವ, ಬೇರ್ಪಡಿಸುವಿಕೆ, ಮತ್ತು ಧೂಳು ಸಂಗ್ರಹ ವ್ಯವಸ್ಥೆಗಳು, ಸಾಮಾನ್ಯವಾಗಿ ಶ್ರೇಣಿಗಳು $70,000-$250,000 ಯಾಂತ್ರೀಕೃತಗೊಂಡ ಮಟ್ಟ ಮತ್ತು ಚೇತರಿಕೆಯ ದಕ್ಷತೆಯನ್ನು ಅವಲಂಬಿಸಿರುತ್ತದೆ. ಮತ್ತು ಅನುಸ್ಥಾಪನೆಯು ಯಾಂತ್ರಿಕ ಜೋಡಣೆಯನ್ನು ಒಳಗೊಂಡಿರುತ್ತದೆ, ವಿದ್ಯುತ್ ವೈರಿಂಗ್, ಮತ್ತು ಸಿವಿಲ್ ಫೌಂಡೇಶನ್ ಕೆಲಸ. ಭಾರತದಲ್ಲಿ, ಇದು ಸಾಮಾನ್ಯವಾಗಿ 10% –15% ಸಲಕರಣೆಗಳ ವೆಚ್ಚವನ್ನು ಸೇರಿಸುತ್ತದೆ, ಸುಮಾರು $7,000-$37,500. ಆಗ, ಹೆಚ್ಚುವರಿ ವೆಚ್ಚಗಳು ಕನ್ವೇಯರ್ಗಳನ್ನು ಒಳಗೊಂಡಿರಬಹುದು, ಶೇಖರಣಾ ಸಿಲೋಸ್, ಮತ್ತು ಪರಿಸರ ಸಂರಕ್ಷಣಾ ಘಟಕಗಳು (ಧೂಳು ಸಂಗ್ರಹಣೆದಾರರು, ನೀರು ಚಿಕಿತ್ಸೆ). ಇದಕ್ಕೆ ಅಗತ್ಯವಾಗಬಹುದು $10,000-$30,000 ಗ್ರಾಹಕೀಕರಣವನ್ನು ಅವಲಂಬಿಸಿರುತ್ತದೆ.

ನಿಯೋಜನೆ ಮತ್ತು ತರಬೇತಿ

ಕಾರ್ಯವು ಸ್ಥಿರ output ಟ್ಪುಟ್ ಗುಣಮಟ್ಟದೊಂದಿಗೆ ಪೂರ್ಣ ಸಾಮರ್ಥ್ಯದಲ್ಲಿ ಕಾರ್ಯನಿರ್ವಹಿಸುತ್ತದೆ ಎಂದು ಖಚಿತಪಡಿಸುತ್ತದೆ. ಈ ಹಂತವು ಸಾಮಾನ್ಯವಾಗಿ ವೆಚ್ಚವಾಗುತ್ತದೆ $5,000-$10,000, ಪರೀಕ್ಷಾ ರನ್ಗಳನ್ನು ಒಳಗೊಂಡಿರುತ್ತದೆ, ಮಾಪನಾಂಕ ನಿರ್ಣಯ, ಮತ್ತು ಕಾರ್ಯಕ್ಷಮತೆ ಆಪ್ಟಿಮೈಸೇಶನ್. ಮತ್ತು ಸುರಕ್ಷಿತ ಮತ್ತು ಪರಿಣಾಮಕಾರಿ ಕಾರ್ಯಾಚರಣೆಯನ್ನು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಸಿಬ್ಬಂದಿ ತರಬೇತಿ ನಿರ್ಣಾಯಕವಾಗಿದೆ. ಸಲಕರಣೆಗಳ ಪೂರೈಕೆದಾರರು ಒದಗಿಸುವ ತರಬೇತಿ ಕಾರ್ಯಕ್ರಮಗಳು ವೆಚ್ಚವಾಗಬಹುದು $3,000-$6,000, ಕೈಪಿಡಿಗಳು ಸೇರಿದಂತೆ, ಆನ್-ಸೈಟ್ ಅವಧಿಗಳು, ಮತ್ತು ಸುರಕ್ಷತಾ ಕಾರ್ಯಾಗಾರಗಳು.

ಕಾರ್ಯಾಚರಣೆ ಮತ್ತು ಸೌಲಭ್ಯ ವೆಚ್ಚಗಳು

ಭಾರತೀಯ ಕೈಗಾರಿಕಾ ವಲಯದಲ್ಲಿ ಸುಮಾರು 500–800 m² ಮಧ್ಯಮ ಗಾತ್ರದ ಕೈಗಾರಿಕಾ ಸೌಲಭ್ಯಕ್ಕಾಗಿ, ಮಾಸಿಕ ಬಾಡಿಗೆ ಸಾಮಾನ್ಯವಾಗಿ $1,500-$3,000, ನಗರದಿಂದ ಬದಲಾಗುತ್ತಿದೆ (ಮುಂಬೈ ಅಥವಾ ದೆಹಲಿಯಲ್ಲಿ ಹೆಚ್ಚು, ಶ್ರೇಣಿ -2 ನಗರಗಳಲ್ಲಿ ಕಡಿಮೆ). ಮತ್ತು ಒಂದು ಸಣ್ಣ ಸಸ್ಯದ ಅಗತ್ಯವಿರುತ್ತದೆ 8-12 ಕೆಲಸಗಾರ, ಸುತ್ತಲಿನ ಪ್ರತಿ ವ್ಯಕ್ತಿಗೆ ಮಾಸಿಕ ವೇತನದೊಂದಿಗೆ $250-$400. ವಾಡಿಕೆಯ ನಿರ್ವಹಣಾ ವೆಚ್ಚಗಳು ಸಾಮಾನ್ಯವಾಗಿ ವಾರ್ಷಿಕವಾಗಿ 3% –5% ಸಲಕರಣೆಗಳ ವೆಚ್ಚಕ್ಕೆ ಸಮಾನವಾಗಿವೆ. ಹೆಚ್ಚುವರಿಯಾಗಿ, ಚೂರುಚೂರು ಮಾಡಲು ವಿದ್ಯುತ್ ಬಳಕೆ, ಪುಡಿಮಾಡುವ, ಮತ್ತು ಪ್ರತ್ಯೇಕತೆಯು ಪ್ರತಿ ಟನ್ ಫಲಕಗಳಿಗೆ 150-200 ಕಿ.ವಾ.ಗೆ ತಲುಪಬಹುದು. ಭಾರತೀಯ ಸರಾಸರಿ ವಿದ್ಯುತ್ ದರದಲ್ಲಿ $0.10 ಪ್ರತಿ kwh, ಶಕ್ತಿಯ ವೆಚ್ಚಗಳು ಇರಬಹುದು $15-$20 ಪ್ರತಿ ಸ್ವರಕ್ಕೆ.

ಉಪಕರಣಗಳನ್ನು ಸಂಯೋಜಿಸುವಾಗ, ಸ್ಥಾಪನೆ, ನಿಯೋಜನೆ, ತರಬೇತಿ, ಮತ್ತು ಬಾಡಿಗೆ ಮತ್ತು ಕಾರ್ಯಾಚರಣೆಯ ಮೊದಲ ವರ್ಷ, ಎ 1000 ಭಾರತದಲ್ಲಿ ಕೆಜಿ/ಎಚ್ ಸ್ಥಾವರ ನಡುವೆ ಬೀಳುವ ನಿರೀಕ್ಷೆಯಿದೆ $120,000-$350,000. ಈ ಶ್ರೇಣಿ ತಂತ್ರಜ್ಞಾನ ಮಟ್ಟವನ್ನು ಅವಲಂಬಿಸಿರುತ್ತದೆ, ಸ್ಥಳ, ಮತ್ತು ಪರಿಸರ ಅನುಸರಣೆ ಅವಶ್ಯಕತೆಗಳು.

ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಪ್ಲಾಂಟ್ ಸೆಟಪ್ಗಾಗಿ ನಾವು ಎಷ್ಟು ಸಮಯದವರೆಗೆ ಯಂತ್ರಗಳನ್ನು ಸ್ವೀಕರಿಸಬಹುದು?

ಅಂತಿಮವಾಗಿ, ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಸಲಕರಣೆಗಳ ಬಗ್ಗೆ ಗ್ರಾಹಕರು ಕೇಳಿದರು., ಮುಂಬೈ. ಇದಕ್ಕಾಗಿ, 1000 ಕೆಜಿ/ಗಂ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಯಂತ್ರಗಳ ಉತ್ಪಾದನೆಯಿಂದಾಗಿ, ಇದಕ್ಕೆ ಸಾಮಾನ್ಯವಾಗಿ ಅಗತ್ಯವಿರುತ್ತದೆ 35-50 ದೆವ್ವ. ಇಲ್ಲಿ,ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಉಪಕರಣಗಳು ಮುಗಿದ ನಂತರ ಮತ್ತು ನೈಜತೆಯನ್ನು ಒದಗಿಸಿದಾಗ ನಾವು ನಿಮಗೆ ತಿಳಿಸಬಹುದು- ಸಮಯ ಸಾಗಣೆ ಮಾಹಿತಿ.

ಮೇಲಿನವು ಗ್ರಾಹಕರೊಂದಿಗಿನ ನಮ್ಮ ಸಂವಹನದ ಬಗ್ಗೆ ವಿವರಗಳು ಸುಮಾರು 1000 ಕೆಜಿ/ಗಂ ಸೌರ ಫಲಕ ಮರುಬಳಕೆ ಸ್ಥಾವರ ಭಾರತದಲ್ಲಿ ಪ್ರಾರಂಭವಾಗುತ್ತದೆ. ಹೆಚ್ಚುವರಿಯಾಗಿ, ನಾವು ನಿಮಗೆ ಅನೇಕ ಇತರ ಇ-ತ್ಯಾಜ್ಯ ಮರುಬಳಕೆ ಯೋಜನೆಗಳನ್ನು ಸಹ ಒದಗಿಸಬಹುದು. ಉದಾಹರಣೆಗೆ ಲಿಥಿಯಂ ಬ್ಯಾಟರಿ ಮರುಬಳಕೆ ಪ್ರಕ್ರಿಯೆ, ತ್ಯಾಜ್ಯ ಟೈರ್ ಮರುಬಳಕೆ ಯೋಜನೆ, ಪ್ಲಾಸ್ಟಿಕ್ ಪೈರೋಲಿಸಿಸ್ ಸಸ್ಯ, ಇತ್ಯಾದಿ. ನಿಮ್ಮ ಇ-ತ್ಯಾಜ್ಯ ಮರುಬಳಕೆ ಸಸ್ಯಗಳಿಗೆ ಉತ್ತಮ ಪರಿಹಾರಕ್ಕಾಗಿ ನಮ್ಮನ್ನು ಸಂಪರ್ಕಿಸಲು ಸ್ವಾಗತ!

ನಮ್ಮನ್ನು ಸಂಪರ್ಕಿಸಿ