Minangka kendharaan energi energi anyar (Nev) pasar terus nggedhekake eksponensial, Jeksa Agung bisa ngetokake kendharaan kendaraan wis muncul minangka aspek penting kanggo pangembangan sing sustainable industri. Dening 2025, Kita ngarepake daur ulang ora mung dadi kabutuhan kanggo perlindungan lingkungan nanging uga sumber daya sumber daya lan ekonomi sing berharga. Kanthi nambah nomer pungkasan-of-of-life, Cara lan prasarana lan infrastruktur sing tepat bakal penting kanggo ngatasi volume kendharaan sing dibuwang.

Sampeyan bisa daur ulang bagean kendharaan energi anyar?

Barang daur ulang ing kendharaan listrik energi anyar (Nev) Lumahing

Gelas jendela Nev bisa disulam lan didaur ulang. Proses iki kalebu bejat gelas dadi potongan cilik, sing banjur bisa dilebur lan diowahi dadi produk kaca anyar, Ngurangi kabutuhan bahan mentah prawan.

Kajaba iku, Plastik Awak Mobil, sing digunakake ing manufaktur kendaraan modern kanggo properti sing entheng lan awet, bisa ulig lan diproses kanggo ngasilake mupangat ekonomi. Plastik daur ulang iki bisa digunakake ing macem-macem industri, kayata produksi pelet plastik kanggo manufaktur komponen plastik anyar utawa ing industri konstruksi kanggo aplikasi non-struktural.

Bahan daur ulang ing mobil listrik energi energi

Batré Lithium ing kendharaan baterei energi baterei energi anyar (BEV) minangka sumber logam sing larang regane. Batré kasebut ngemot unsur kaya lithium, Kobalt, Nikel, lan mangan, sing cocog karo produksi baterei anyar. Liwat teknik daur ulang maju, Metals larang regane iki bisa dibalekake lan digunakake maneh, Ngurangi ketahanan babagan pertambangan lan dampak lingkungan sing gegandhengan.

Batré Lithium ing kendharaan baterei energi baterei energi anyar (BEV) minangka sumber logam sing larang regane. Batré kasebut ngemot unsur kaya lithium, Kobalt, Nikel, lan mangan, sing cocog karo produksi baterei anyar. Liwat teknik daur ulang maju, Metals larang regane iki bisa dibalekake lan digunakake maneh, Ngurangi ketahanan babagan pertambangan lan dampak lingkungan sing gegandhengan.

Mesin apa sing bisa daur ulang bahan sing larang regane ing energi evs energi anyar

Nalika daur ulang cangkang mobil saka energi anyar, Daya abot Mesin Shredding penting. Shredder iki bisa ngatasi struktur logam sing gedhe lan kuwat. Umpamane, Hydraulic Crushers kanthi motor sing kuat bisa meksa tekanan kanggo ngrusak badan mobil dadi potongan sing luwih cilik. Biasane duwe kamar ngremehake gedhe lan rahang sing bisa luwes kanggo nyukupi macem-macem macem-macem bagean. Kekuwatan saka crushers kaya ngono 50 kw ke 150 kw, Ngilangake dheweke kanggo ngolah lembar logam tebal saka cangkang mobil.

Kanggo daur ulang kaca jendhela, Crushers khusus dibutuhake. Crushers iki asring dilengkapi agul-agul sing santai lan sistem feeder kedher. Bledes digawe saka wesi sing berkualitas tinggi kanggo tahan keras saka gelas. Paman bahan kedher njamin langkah-langkah gelas kanggo wilayah sing diganggu. Sawetara dandan kaca majeng bisa entuk ukuran crughing kaya cilik 1 - 5 mm, sing penting kanggo pangolahan lan pemisahan komponen kaca. Konsumsi kekuwatan para remaja iki cukup mudhun dibandhingake karo badan mobil, biasane ing sekitar 10 kw ke 30 kw.

Papan sirkuit ing energi anyar EVE ngemot logam lan komponen sing larang regane. Crushers dirancang kanggo papan sirkuit kudu luwih tepat lan lembut supaya ora ngrusak bahan sing larang regane. Biasane makarya kombinasi pasukan lan pengaruh mekanik. The Crushers duwe roller sing apik banget lan mekanisme ngremehake sing dikontrol kanggo ngilangi papan sirkuit dadi fragmen cilik nalika njaga integritas logam lan semikonduktor. Kekuwatan The Crushers iki umume ing kisaran 20 kw ke 50 kw.

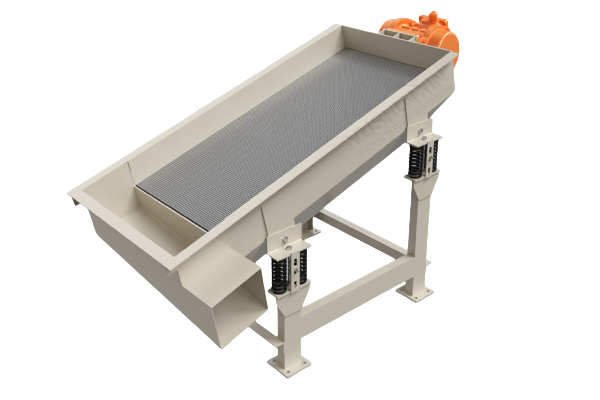

Layar kedhèb Kanthi ukuran bolong sing beda-beda digunakake. Layar kasebut bisa misahake bahan-bahan ulig adhedhasar ukuran partikel. Umpamane, Layar kedher kanthi ukuran bolong saka 2 - 10 mm bisa kanthi efektif partikel aluminium saka lebu non-metalik. Efisiensi screening penting kanggo njamin kesucian unsur logam sing wis pulih. Mesin screening dilengkapi sistem kontrol cerdas kanggo nyetel frekuensi lan amplitudo getar, Ngoptimalake proses pamisahan.

Layar getar magnetik digunakake digunakake kanggo misahake unsur logam. Gambar kasebut nggunakake sifat-sifat magnetik logam kanggo narik kawigaten lan misahake saka bahan non-metalik. Dheweke kalebu dek kedher kanthi magnet sing dibangun lan sistem drive variabel frekuensi. Kekuwatan Magnetik bisa diatur miturut jinis lan ukuran partikel logam sing bakal dibalekake. Umpamane, Kanggo fragmen logam cilik, Kekuwatan lapangan Magnetik saka 2000 - 3000 Gauss cukup, Nalika potongan sing luwih gedhe mbutuhake lapangan sing luwih kuat 4000 - 5000 Gauss. Gerakan kedher mbantu mindhah bahan ing sadawane lumahing layar, allowing the metal particles to be captured by the magnets and diverted to a separate collection chute. Kajaba iku, our screen mesh size can be customized, typically ranging from 0.5 mm to 5 mm, to further refine the separation process and ensure the purity of the recovered metal elements.

Kesimpulan, the recycling of valuable materials in new energy EVs requires a combination of specialized recycling machines, each tailored to the specific characteristics of the materials being recycled. If you are an enterprise or individual interested in delving deeper into the field of new energy vehicle parts recycling, or if you have any questions regarding the selection of recycling equipment, contact us please. Our team is here to assist you.

Cara njamin proses daur ulang mobil sampah minangka polusi gratis

By implementing these pollution prevention measures, you can ensure that the waste car recycling process is environmentally friendly. We specialize in providing top-notch e-waste recycling solutions including dust removal. You can reach out to us via our contact form. We look forward to helping you enhance the environmental performance of your e-waste recycling business through our high-quality dust removal equipment.

Kepiye cara daur ulang bagean kendharaan energi anyar nggawa bathi sampeyan?

In 2025, the recycling of new energy electric vehicle parts offers great economic promise. Advanced recycling technologies help unlock the value of discarded vehicles.

We manufacture professional recycling equipment with CE lan ISO certifications. Our offerings include lithium – battery recycling machines, solar panel recycling equipment, circuit – board recycling lines, lan tire pyrolysis production line equipment.

If you’re interested in the new energy EV recycling business and unsure about equipment choices, contact us without hesitation.

Hubungi kita