SU 24 ottobre, Abbiamo ricevuto un'indagine da un cliente tedesco su impianto di riciclaggio della pirolisi dei pneumatici per rifiuti in Germania. Il cliente vuole saperne di più su YSX Waste Tire macchine per pirolisi. Perché la Germania offre sussidi finanziari e incentivi per il riciclaggio, e la Germania produce milioni di pneumatici all'anno, Quindi hanno un grosso problema di gestione dei pneumatici per rifiuti. Pirolisi, una forma di Wte, Potrebbe essere la risposta. Il cliente vuole sapere se la tecnologia di pirolisi può essere utilizzata per il recupero dei pneumatici e come. Quello che segue è ciò di cui abbiamo parlato con il cliente tedesco.

Come costruire una struttura di pirolisi dei pneumatici in Germania in 3 Passi?

Il mercato tedesco dei pneumatici è enorme e dovrebbe crescere in un CAGR di 3.80% durante 2024-2032. Con sufficiente rifornimento di gomme di scarto come materie prime, I nostri clienti tedeschi sono interessati a creare un impianto di pirolisi dei pneumatici. Hanno chiesto informazioni sui dettagli della creazione di un impianto per avviare l'attività in quanto stanno prendendo in considerazione l'utilizzo per i progetti di gestione e riciclaggio dei pneumatici di scarto. Per rispondere alle loro domande sulla pirolisi dei pneumatici di scarto, Cominciamo con tre passaggi.

Preparati per la pianta di pirolisi dei pneumatici

Fare un passo 2 Costruire un impianto di pirolisi dei pneumatici in Germania

Fare un passo 3 Per costruire una struttura di pirolisi dei pneumatici in Germania

Quali sono i prodotti della pirolisi dei pneumatici?

Come scegliere forni di pirolisi per la pianta di pirolisi dei pneumatici?

Then we keep discussing with the German client. The client wants to set up a pyrolysis plant to recycle tyres and other rubber waste. They inquire which pyrolysis furnaces are best for their recycling plant.

Actually when choosing a tire pyrolysis furnace, it’s essential to consider different operating modes such as Lotto, Semi – continuous, E Fully continuous.

Performance ed efficienza del forno

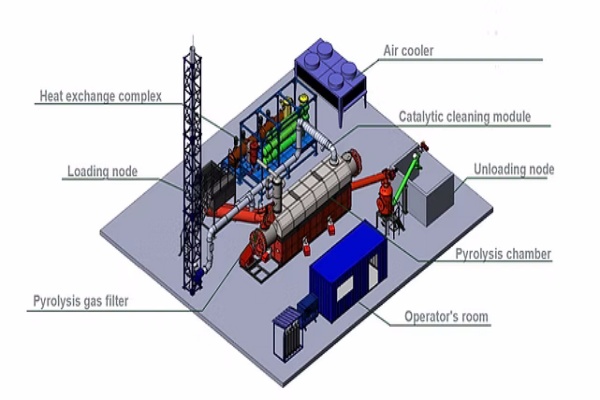

Installazione dell'impianto di pirolisi

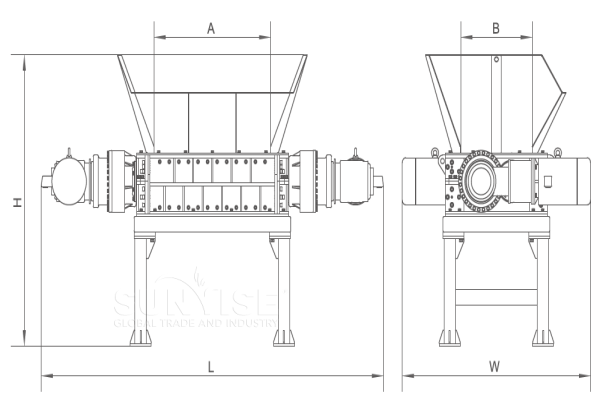

Macchina di pirolisi del pneumatico

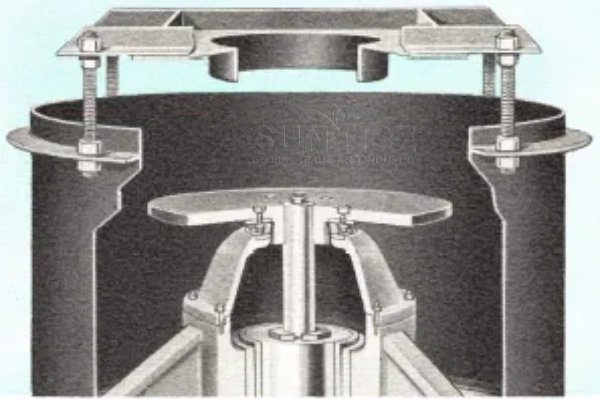

Parametri della fornace di pirolisi di Yushunxin

| Item | Waste pyrolysis unit | ||

| Equipment type | Lotto | Semi-continuous | Fully continuous |

| Raw materials | Rubber tyres, plastics, oil sludge, coal tar, aluminium plastics, ecc. | ||

| Structure form | Horizontal rotation | ||

| 24-hour capacity | 100 kg-20 tonnes | 10-20 tonnes | 15-50 tonnes |

| Oil yield From | 30-70 per cent | ||

| Operating pressure | Normal | ||

| Pyrolysis reactor material | Q245/345R, boiler plate, stainless steel | ||

| Thickness of pyrolysis reactor | 14, 16, 18, 20 mm | ||

| Speed of pyrolysis reactor | 0.4 rpm | ||

| Total power | ≤ 30KW | ||

| Cooling mode | Circulating water cooling | ||

| Condenser cooling area | 100 square metres | ||

| Type of transmission | Internal gearing | ||

| Peso | Depending on size | ||

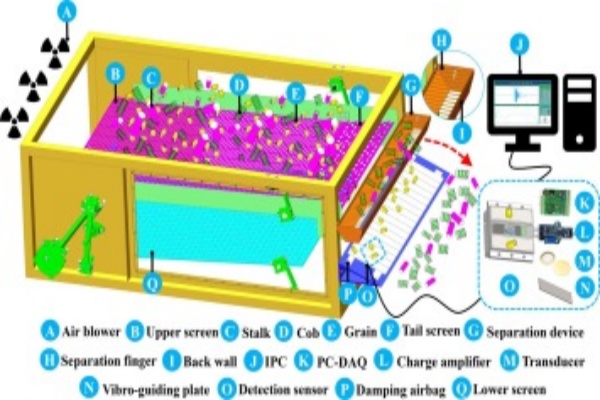

Resa media dell'olio nell'impianto di pirolisi dei pneumatici per i rifiuti con l'auto-alimentatori

Quanto profitto puoi realizzare dal riciclaggio della pirolisi dei pneumatici?

The client wants to invest in a tyre-recycling plant now. Perciò, they asked about the profit from tyre pyrolysis recycling. “We wanted to know how much money this recycling production line could make.” This is also a question that most customers are very concerned about. Actually this depends on many things.

Scala della tua pianta di pirolisi

Prezzi del prodotto di pirolisi e domanda di mercato

C'è qualche riferimento personalizzato per la soluzione di pirolisi del pneumatico di scarto?

oLet’s differentiate based on processing capacity. The following we’ll provide you with German waste tire pyrolysis recycling production line of different scales for reference. Customers can make adjustments as needed:

Piccolo PROPOSIZIONE DEL PIROLISI PIROLISI PROPOSIZIONE (Adatto per start-up o produzione sperimentale)

The daily processing volume of waste tires is about 1-2 tons, mainly producing rubber particles, some fili di acciaio, E olio di pirolisi.

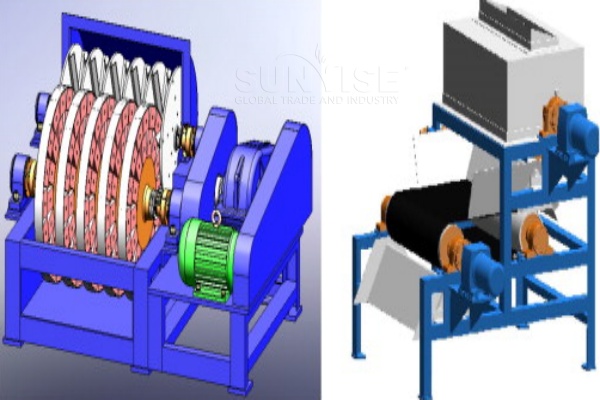

Prima della pirolisi

Macchina di pirolisi(opzionale)

Altri aspetti della soluzione di pirolisi

Medio Soluzione della linea di produzione di riciclaggio dei pneumatici (mercato regionale)

The daily processing volume of waste tires is 5-10 tons, and high-quality rubber particles and high-quality carbon black are produced for tire retreading or high-end rubber production, and recycled steel wire is sold. The pyrolysis oil meets the industrial fuel standard and is partly used for self-use and partly sold.

Prima della pirolisi

Macchina di pirolisi(opzionale)

Continuous tire pyrolysis furnace: It produces 1-2 tons of pyrolysis oil and 0.8-1.2 tons of carbon black per day, uses natural gas or biomass particles as fuel, has a thermal efficiency of more than 70%, and is equipped with waste heat recovery for drying and other links.

Altri aspetti della soluzione di pirolisi

Su larga scala Piano di linea di produzione di riciclaggio dei pneumatici (Cluster industriale)

Daily processing of 20 tons or more of waste tires, large-scale production of high-quality rubber product raw materials, Black di carbonio, and steel wire, and pyrolysis oil for park energy or external sales.

Layout dell'attrezzatura prima della pirolisi

Pirolisi e cluster di utilizzo profondo

High-efficiency large-scale pyrolysis furnace group: multiple continuous pyrolysis furnaces in parallel, daily output of 5-8 tons of pyrolysis oil and 3-5 tons of carbon black, advanced heat recovery and automatic control to ensure stable operation.

Carbon black modification and granulation production line: Deep modification and granulation of carbon black to meet the needs of tires and high-end rubber, with strong product competitiveness; pyrolysis oil refining device purification reaches the high-quality standard of fuel oil.

Altri aspetti della soluzione di pirolisi

Perché scegliere YSX come fornitore di fornace di pirolisi?

Che cosa Qualifiche Abbiamo?

At SUNRISE, CE E Iso 9001 certifications are just part of our offerings in this regard. We’ve got a whole slew of other certifications up our sleeve to meet diverse compliance and quality benchmarks as well.

Cliente Immagini di feedback di pianta di pirolisi

Finalmente, our German customers want to know how pyrolysis works in specific production case studies. This can help them decide if this technology is right for them. Let’s take a look at some great examples. Click here to know more.

YSX team can provide you not only the tire reycling solutions, but also e-waste disposal plan like batteries recycling solutions, circuit board recycling solutions, E solar panel reycling solutions. Feel free to contact us if you wanna start recycling business.

Contattaci