Waste Tire Pyrolyse-plant dy't effisjint-banden konverteart, ôffalbanden yn weardefolle produkten lykas Pyrolyse oalje, koalstof swart, stiel draad, en brânbere gas fia it Pirolysis proses. Dizze avansearre recycling-technology behannelet net allinich it groeiende probleem fan bânfersmoarging, mar soarget ek in heul rendabele saaklike kâns. Bestjoer, mei tanimmende wrâldwide fraach nei eco-freonlike oplossingen, Yushunnxin Waste Tire Pyrolyse-apparatuer is in ideale kar wurden foar duorsume bân-recycling. Let’s explore more details about this powerful waste tyre recycling system.

Wat is it wurkproses fan ôffalbanden pyrolyse plant?

Load Waste Tyres into the Tyre Pyrolysis Machine

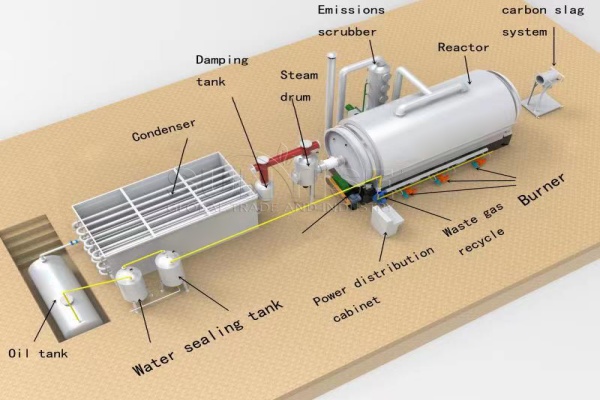

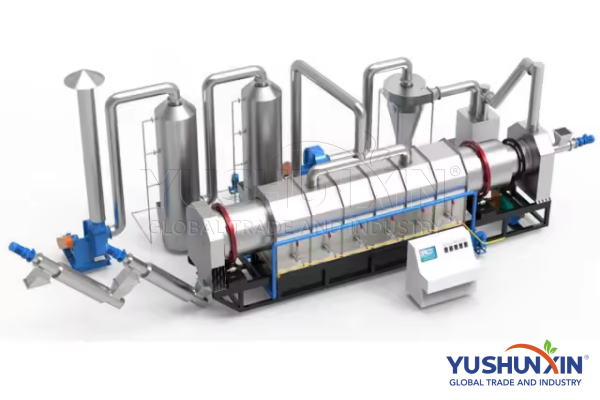

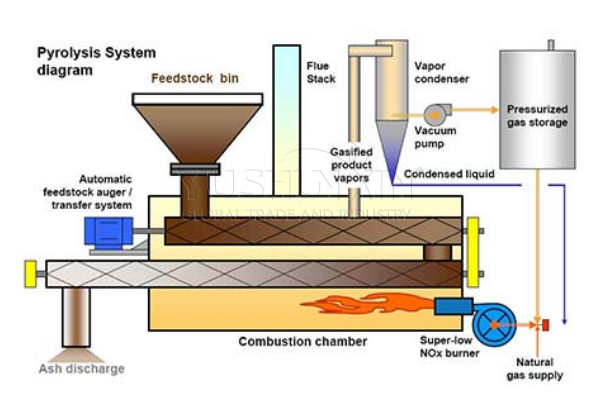

Start by feeding waste tyres into the reactor of the tyre pyrolysis machine through an automatic feeder. Make sure to load only two-thirds of the reactor’s capacity to ensure smooth and efficient rotation during processing. Once the tyres are in, securely close the feeding door to begin the waste tyre to oil conversion process.

Heat the Reactor and Begin Oil-Gas Separation

Heat the reactor using available fuels such as coal, wood, natural gas, or pyrolysis oil from the previous cycle. As the temperature reaches 100°C, oil and gas begin to form. To achieve the highest oil yield, maintain the reactor temperature between 250°C and 280°C. The system separates heavy oil gas in the manifold and channels it into a heavy oil tank after liquefaction. Underwilens, lighter oil vapors pass through the pyrolysis oil condenser, turn into liquid, and are stored. Non-condensable gases are filtered and recycled back to the furnace for heat generation, improving fuel efficiency.

Cool the Reactor and Recover Carbon Black

After completing the oil production, allow the reactor to cool naturally. When the temperature drops by 40°C, the machine will automatically discharge carbon black into a collection system. If processing whole tyres, wait until the temperature falls below 50°C and then use a mechanical hook to extract the steel wires. This step completes the carbon black recovery process.

Reset foar de folgjende pyolysyklus

Foardat jo begjinne mei de folgjende batch, Befêstigje dat alle materialen binne fuorthelle, De reaktor is genôch koele, en alle feiligenskontrôles binne folslein. Dizze tarieding is krúsjaal om de prestaasjes fan 'e lange termyn te behâlden fan' e TIRE Pirolyse-plant en om konsekwint ôffalbân te garandearjen oan oaljekonvering.

Wat is it gebrûk fan definitive produkt fan pyolysis fan ôffalbanden?

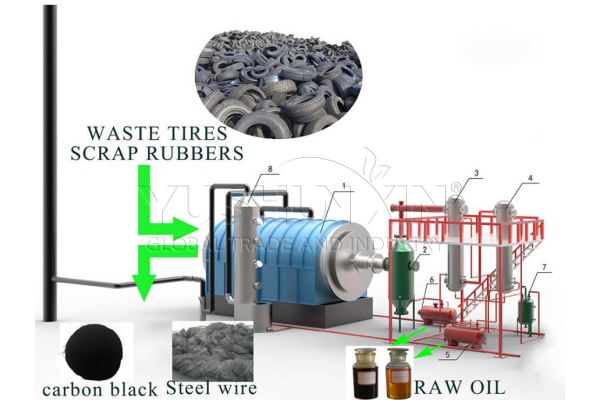

De plant fan 'e ôffalbanden is in rendabel en eko-freonlik wurden Oplossing foar Tyre Recycling. Dit proses fermindert net allinich omjouwende fersmoarging allinich, mar genereart ek meardere weardefolle einprodukten dy't breed kinne wurde tapast oer industries. Here is a breakdown of the four main products generated during the pyrolysis process and their respective market applications:

The pyrolysis process extracts pyrolysis oil, which contains useful compounds such as benzene, toluene, xylene, styrene, dimer pentene, trimethylbenzene, and tetramethylbenzene. These substances are commonly used as chemical raw materials in various industries.

Bestjoer, this oil serves as a substitute for diesel in steel plants, cement factories, boiler systems, and heavy oil generators. With further distillation, pyrolysis oil can be refined into diesel fuel, making it a high-demand energy product in both industrial and transportation sectors.

The process also produces carbon black, which is primarily used as a reinforcing filler in low-grade rubber manufacturing, including tire production and rubber soles. Oanfoljend, carbon black acts as a pigment for inks and paints.

In its raw form, it can be directly used as solid fuel. However, with further milling and refining, it can be upgraded into activated carbon, opening up opportunities in filtration, purification, and chemical adsorption markets, where demand continues to grow.

Waste tyres contain embedded spring steel wire, which remains intact during pyrolysis due to the low-temperature, oxygen-free environment. This ensures that the mechanical properties of the steel are preserved.

After separation, this high-quality steel can be resold to metal processing or remelting industries, offering a lucrative return and supporting the circular economy in the metallurgical field.

During pyrolysis, a significant amount of combustible gas is generated. Rather than releasing it, the plant recycles this gas as an internal fuel source for heating the reactor itself. This closed-loop system reduces operational costs and minimizes harmful emissions, improving both energy efficiency and environmental performance.

Waste tire pyrolysis plant price solution

Looking for an affordable and efficient waste tire pyrolysis plant? Whether you’re a small recycler or a large-scale investor, It kiezen fan it juste kapasiteit en priisberik is krúsjaal foar ROI EN LAND-termyn stabiliteit.

| Kapasiteit (TONS / DAG) | Type | Ynskatte priis (USD) | Oanrikkemandearre foar |

| 1-3 TPD | Batch | $30,000 - $60,000 | Lytse opstart |

| 5-10 TPD | Semi-kontinu | $65,000 - $120,000 | Planten fan middelgrutte, fleksibele ops |

| 12-20+ TPD | Folslein trochgeande line | $130,000 - $300,000+ | Yndustriële-klasse, grutskalige |

Foai: Pas op om te goedkeapoan oanbiedingen sûnder CE / ISO-sertifikaasjes as juste emissionsbewegers.

Om fierder te helpen jo te helpen de winst te kennen fan 'e plant fan ôffalbanden, Wy kinne jo leverje mei winstanalyse fan 12T / D / D ôffalbân Pirolyse plant.

| Rinnende kosten / dei | |

| Ôffalbanden | 12T * 73USD / T = 876USD |

| Ferwaarme brânstof (Kies gewoan ien fan 'e opsjes) |

1) Stienkoal: 0.4T * 58USD / T = 23USD 2) Brânstof oalje: 0.4T * 364USD / T = 146USD 3) Diesel: 0.3T * 582USD / T = 175USD 4) Ierdgas: 150M3 * 0.33USD / M3 = 4.9USD |

| Krêft konsumpsje | 15Kw / h |

| Wetterferfal | Wetter is foar sirkulearjend gebrûk, Gjin konsumpsje |

| Fereaske arbeiders | 3 arbeiders per ferskowing * 22USD = 65USD |

| Ynkommen / Dei | |

| Fuel oalje | 4.5T * 364USD / T = 1637usd |

| Koalstof swart | 1) Ferkeapje direkt, 3T * 73USD / T = 218USD 2) Slining, 3T * 291USD / T = 873USD |

| Stiel draad | 1.5T * 116USD / T = 175USD |

| Deistige winst (Brûk brânstof oalje foar it ferwaarmjen fan en ferkeapje koalstof swart) |

1302USD / dei |

Wat mear fabrikanten wolle witte oer it plant fan ôffalbiere Pirolyse?

Oer Tyrolys fan ôffalbân, Jo kinne miskien in protte oare dingen wolle witte. D'r binne guon items faak frege fan ús klanten- ôffalbân recycleer foar jo referinsje. As jo mear ynformaasje nedich binne fan banden pyrolyse en masines, Wolkom om ús fuortendaliks te freegjen.

As in ôffalbase Pyrolyse plantfabrikant mei 10 jierren fan rike ûnderfining, Yushunnxin kin net allinich kinne leverje oan plant fan hege kwaliteit, but also can configure waste tyre pyrolysis plant according to your specific situation to help you arrange the project schedule. And if you need waste tire crushing and separating line, we can also offer for you. Contact us now for a free quote on waste tyre pyrolysis plant.

Kontakt mei ús opnimme