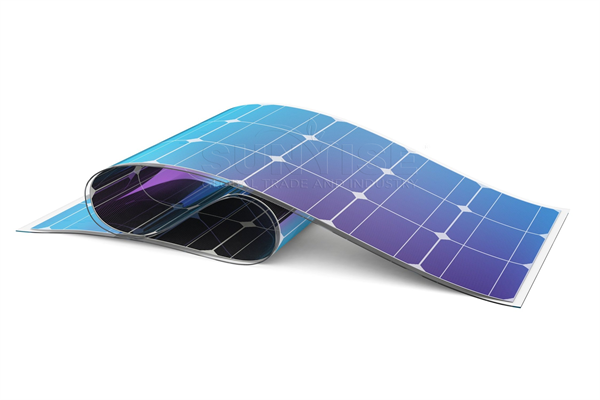

Glavne komponente fotonaponske (PV) Solarni panel sastoji se od visokokvalitetnog stakla, Aluminijski okviri, polimeri, silicijum, bakar, i srebrna pasta. Našim mašinom za recikliranje solarnih panela (rješenja), Možete uspješno reciklirati svaki od ovih materijala, s cijenama za oporavak koji dopiru do 95%.

Kakve solarne ploče se mogu reciklirati?

Ako ne pronađete svoj predmet e-otpada(s) gore navedeno, molim te stupi u kontakt sa nama. Ysx će vam pomoći.

POV ploča okvir za uklanjanje demontaže

Solarna mašina za odbranu fotonaponske ploče pogodna je za demontažu i recikliranje otpadnih solarnih ploča od aluminijskih okvira različitih veličina i vrsta. Prvo, Može precizno ciljati i započeti proces odvajanja aluminijumskog okvira. Naknadno, Tokom ove operacije, uspijeva konačno ukloniti 80%-95% stakla.

SOLARNI PANELS STAKSKI STROJ

Uklanjanje većine stakla sa površine. Širina obrade 1250mm.

Solarni paneli drobilica sa dva osovina

Shredder mogu u početku obrađivati velike količine solarnih panela. Prvo, Brzo ih prekrši u male komade, thereby improving the efficiency of the entire recycling processing line. Naknadno, the smaller material size makes the subsequent equipment (such as sorters, crushers, itd.) work more efficiently.

Crusher (Hammer Mill) for Photovoltaic Panels

Nakon drobijanja, the fragmented materials are passed through a crusher. This machine is designed to further break down materials like glass, silicon wafers, and other components into even smaller particles. Crushing is a critical step in the recycling process as it prepares the materials for separation techniques that will isolate valuable metals and silicon.

What Solar Panel Recycling Machine Sorts Those Materials?

Magnetic Separator

Used to separate iron and other magnetic metals from mixed materials. Magnetic separator uses the attraction of a magnetic field to separate magnetic metals from non-magnetic materials, thereby improving the purity of the material.

Cyclone separator

Cyclone separator is a highly efficient device that employs centrifugal force to effectively separate lighter materials from heavier ones within a mixture. As the mixture is introduced into the cyclone separator, it undergoes rapid spinning, which generates a powerful vortex inside the chamber. This vortex action causes the heavier particles to be flung outward towards the outer edges of the separator. Naknadno, the lighter materials are allowed to stay near the center. As a result, a clear and efficient separation process is facilitated.

High-voltage electrostatic separator

The remaining copper and EVA glue that are not completely separated enter the high-voltage electrostatic separator, which separates the copper based on conductivity.

Gravity Separator

Gravity separator is the innovative device that effectively separates copper and EVA glue based on the varying densities of their particles. By utilizing the principle of gravity, this separator distinguishes materials with different densities. Prvo, it carefully separates the various components of waste solar panels. Through this process, impurities are significantly reduced. Drugo, this enhancement in purity leads to a notable improvement in both the efficiency and precision of the recycling process. As a result, the reuse rate of waste solar panels is substantially increased. Samim tim, it contributes to more sustainable and eco – Prijateljske prakse u upravljanju i recikliranju materijala za solarni panel.

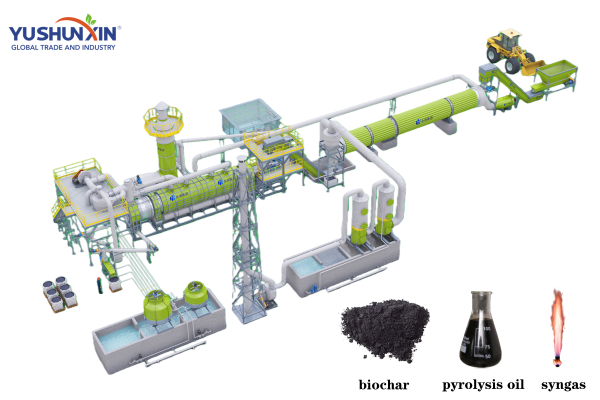

Koja mašina za reciklažu solarne ploče nalazi se u procesu toplotnog obrade?

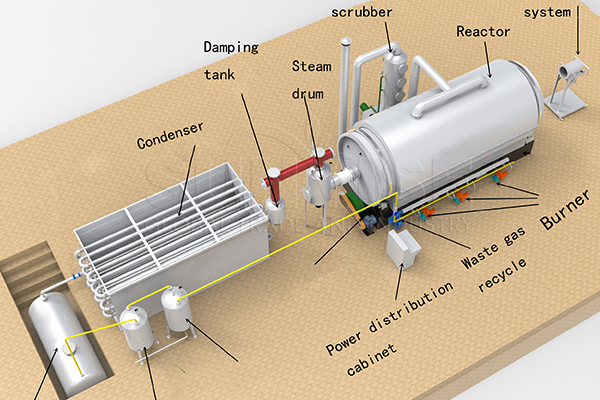

The Perolizna peć stvara visoko – temp, kiseonik – slobodan prostor. Solarni paneli se zagrijavaju 600° C, izazivajući materijale za raspad. Neki se okreću benzini, Odlazak od šljake s teškim metalima koji je potreban dodatni tretman. The Kondenzatna cev pretvara plin u tečnost. The Paket za odvajanje plina pročišćava plin – Tečne smjese. The prskati toranj Čisti ispušni gasovi, Smanjivanje standarda zagađenja i sastanka.

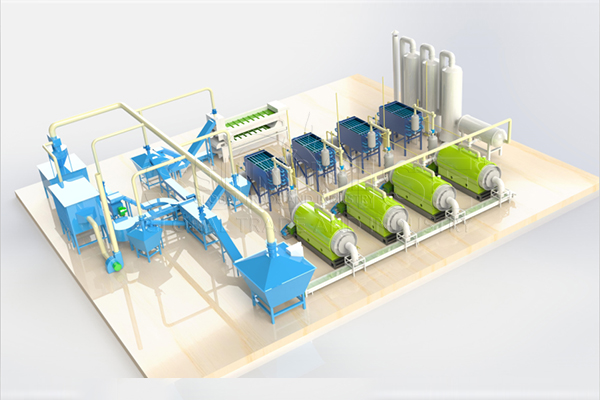

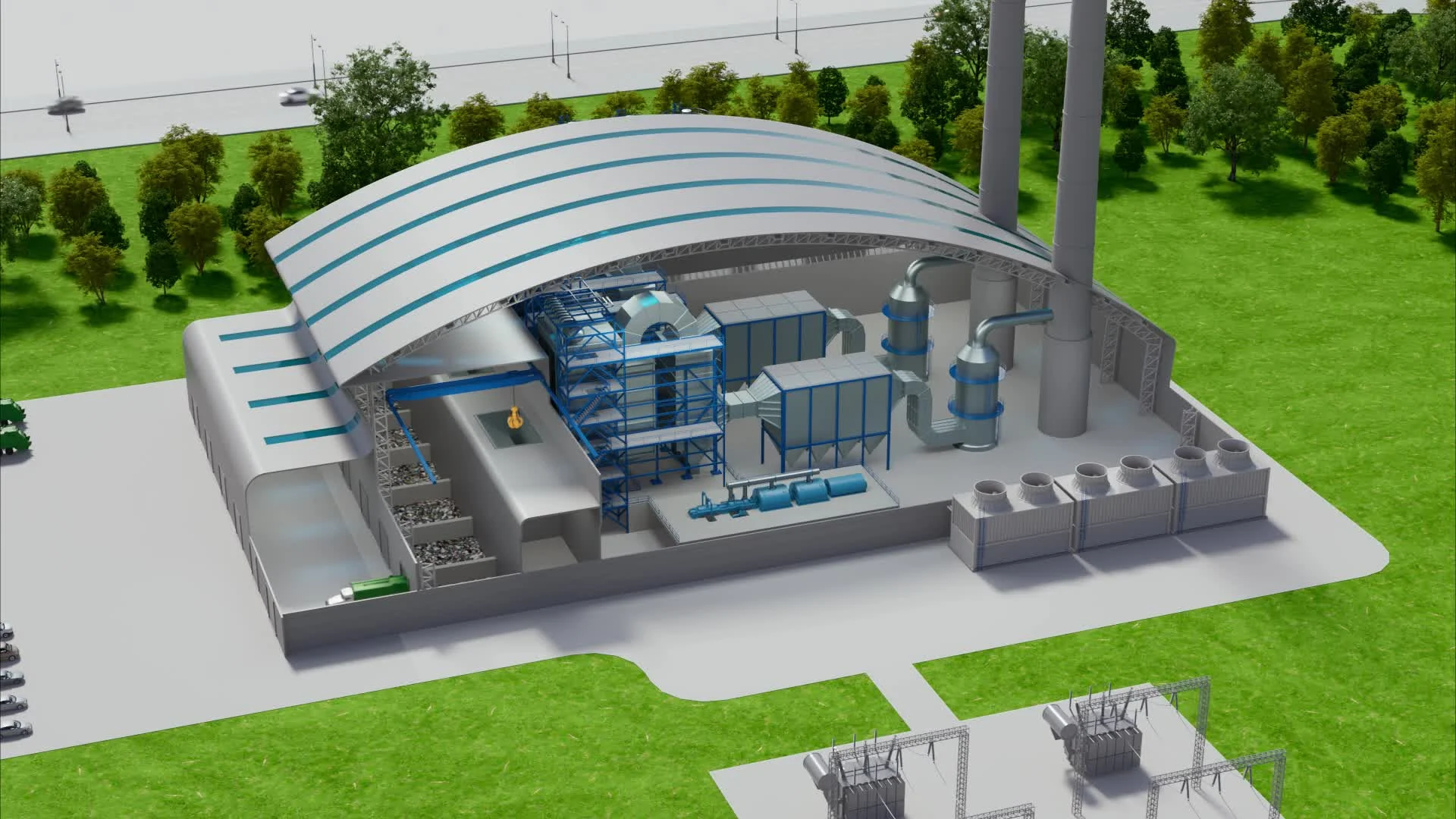

Kako dizajnirati fabriku recikliranja solarnog panela?

What do People Recycle Solar Panels for?

Why Choose YUSHUNXIN as Your Supplier of Solar Panel Recycling Machines?

The Advantages of YSX Solar Panel Recycling Machines

Parametri opreme za recikliranje solarne ploče za vašu referencu

| Model | YSX-300 | YSX-500 | YSX-1000 |

| Kapacitet | 300 Kg / h | 500 Kg / h | 1000 Kg / h |

| Snaga | 102 Kw | 134 Kw | 194 Kw |

| Težina | 15 Tona | 20 Tona | 30 Tona |

| Dimenzija (m) | 20*5*5 | 25*6*5 | 30*6*5 |

Koja je opća cijena reciklažne linije za recikliranje solarne ploče?

Otprilike $50,000 – $70,000. Male linije su pogodne za male do srednje preduzeća ili startupe, Relativno jednostavni i jeftini.

Otprilike $80,000 – $150,000. Pored opreme u malim linijama, Srednje linije zahtijevaju opremu veće specifikacije. Srednje linije zahtijevaju efikasniju opremu i automatizacijski sustavi za rukovanje potrebama srednje prerade.

Otprilike $160,000 – $200,000 ili više. Velike linije trebaju najnaprednija oprema i sustavi za maksimiziranje efikasnosti recikliranja i usklađenosti na okoliš.

Kontaktirajte nas