YSX lithium battery recycling machine production line can be used to recycle cylindrical batteries, prismatic batteries, pouch battery negative plates, positive plates, ወዘተ, which can be directly put into the machine without any processing.

Lithium batteries are mainly composed of shell, positive electrode, negative electrode, electrolyte and diaphragm. The final products are graphite ዱቄት, aluminum particles, copper particles, plastic, steel shell, diaphragm plastic, ወዘተ.

From an environmental protection perspective, our production line is outfitted with top-notch air purification equipment. We’ve installed a water spray system and an activated carbon unit. The water spray system helps to trap and neutralize pollutants, ያገለገለው የካርቦን አሃድ ደስ የማይል ሽታዎችን በማጥፋት ረገድ በጣም ውጤታማ ነው. ከዚያ በላይ, በቦታው ውስጥ የጅምላ አቧራ አቧራ ክምችት ስርዓት አለ. ይህ ስርዓት እንደ ማራኪነት ይሠራል, አጭር, አቧራማ አቧራ አቧራማ ቅንጣቶች ጠንካራ የአየር ጠባቂዎች.

ለሊቲየም ባትሪ ማሻሻያ ማሽኖች ተስማሚ የሆኑ ጥሬ ዕቃዎች

የሊቲየም ባትሪ እንደገና ጥቅም ላይ የዋለው ጥሬ ዕቃዎች የተለያዩ ናቸው. የተንቀሳቃሽ ስልክ li-ion ባትሪዎች, ለስላሳ ጥቅል, 18650, እና አልሙኒኒየም ll ል የሊቲየም ባትሪዎች የተለመዱ ናቸው. የእነሱ አሉታዊ እና አዎንታዊ ሳህኖች, ጠቃሚ ብረትን መያዝ, እንዲሁም ወሳኝ ናቸው. እነዚህ ቁሳቁሶች ሀብቶችን ለማገገም ውጤታማ እንደገና ጥቅም ላይ ለማዋል ቁልፍ ናቸው. እዚህ ያልተዘረዘሩ ሌሎች ዓይነቶች የሊቲየም ባትሪዎች ካሉዎት, ወይም ያገለገሉ ባትሪዎችዎ ከሚያገለግሉ መሳሪያዎች ጋር ተኳሃኝ መሆናቸውን ካልፈቀዱ, ወደኋላ አትበል ወደ YSX INDER ያግኙ. Dept. ለችግሮቻችን ተገቢነትዎን እንገመግማቸዋለን. በተጨማሪም, ለእርስዎ ልዩ መስፈርቶችዎ የሚስማማ ማበጀት አገልግሎቶችን እንሰጣለን.

የሊቲየም-አይት ባትሪዎችን ከመተግበሩ በፊት የሊቲየም ባትሪዎችን መፍታት

በሊቲየም ከፍተኛ ምላሽ ምክንያት, recycling requires extra precautions for safety–battery discharging. ይህ ማለት ነው, አንድ ባትሪ እንደገና ጥቅም ላይ ለማዋል ከመሄድዎ በፊት, የእሳት አደጋ አደጋን ለመቀነስ ሙሉ በሙሉ ሊታወቅ ይገባል. ለአሁን, መፍታት በእነዚህ በርካታ መንገዶች በኩል ይወጣል.

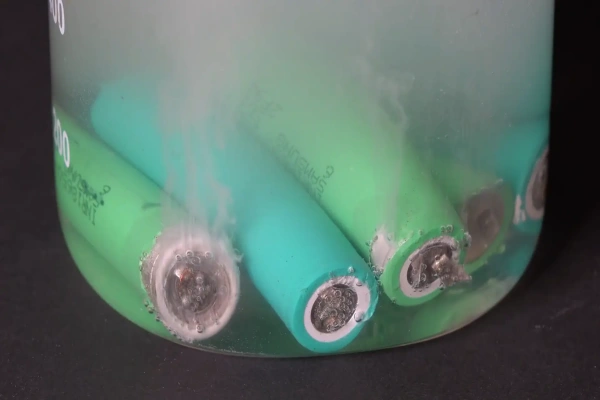

የሊቲየም ባትሪዎች የጨው ውሃ ውሀ ዘዴ

ጥቅሞች:

1. ቀላል እና ቀላል: የጨው የውሃ መውጫ ዘዴ ለማካሄድ ቀላል ነው እና ውስብስብ የሆኑ መሳሪያዎችን ወይም የባለሙያ ቴክኒሻኖችን አይፈልግም.

2. ዝቅተኛ ወጪ: ሁላችንም እንደምናውቀው, የጨው ውሃ ርካሽ እና በቀላሉ የሚገኝ ቁሳቁስ ነው. ስለዚህ, የዚህ ዘዴ አፈፃፀም ዋጋ ዝቅተኛ ነው.

ትኩረት ይስጡ:

1. ዘገምተኛ ፍጥነት: የጨው ውሃ ፈሳሽ ሙሉ በሙሉ ለመፈተሽ ረጅም ጊዜ ሊወስድ ይችላል, ስለ 1-2 ቀናት.

2. ውሃውን በንጹህ ያወጣል: There will have safety hazards if you don’t pay attention on it. Wet batteries may leak, release gas or other dangerous situations.

3. Avoid mixing: Applicable battery types are soft pack, plastic hard shell battery and cylindrical battery. Batteries of other different types or states should not be discharged together to avoid danger.

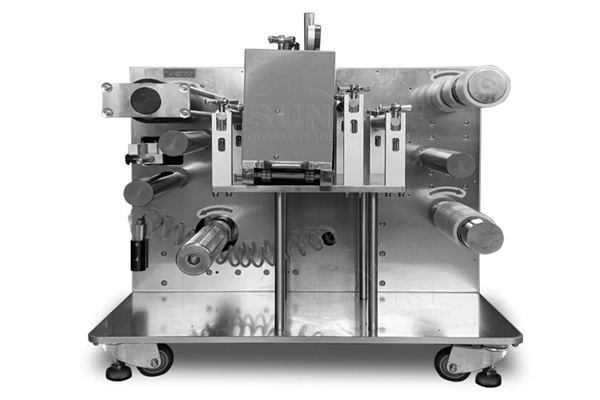

Working Principle:

The charged lithium battery is fed into the gap between the needle roller and the groove roller through the feeder. Through rotation and extrusion, the steel needle attached to the needle roller pierces the inside of the battery, causing a short circuit between the positive and negative electrodes, thereby releasing energy and achieving the purpose of discharge. በተጨማሪ, by adjusting the gap between the two rollers, the discharge requirements of different types of lithium-ion batteries can be met.

Attention:

It is mainly for 3C product batteries such as soft packs and plastic hard shells.

ለሊቲየም ባትሪ የመርከብ መፍሰስ ዘዴ

ለሊቲየም ባትሪዎች ውስጥ ጥቅል ጥቅል መቆረጥ

Working Principle:

Lithium-ion battery roll-cutting discharge equipment works simply. አንደኛ, the rolling part rotates the battery. ከዚያ, a cutter slices open the battery case. Once opened, the positive and negative electrodes inside touch, causing a short – circuit. This short – circuit makes the battery discharge its electricity fast. The equipment also has safety checks, like sensors to monitor heat and smoke.

Attention:

The applicable battery is a cylindrical lithium-ion battery.

የሊቲየም ባትሪዎች እንደገና ጥቅም ላይ የዋሉ?

ባትሪዎቹን ማቀናበር

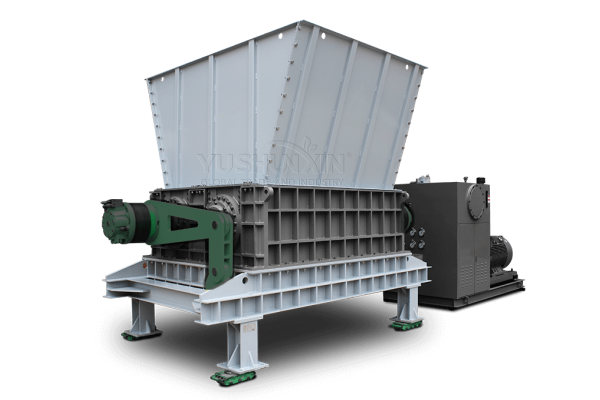

Batteries are fed into a ሽፋሪ to break them into smaller pieces. One shred is 10ሴሜ long and 4ሴሜ wide and the second crushing is 3-4ሴሜ long and 2ሴሜ wide.

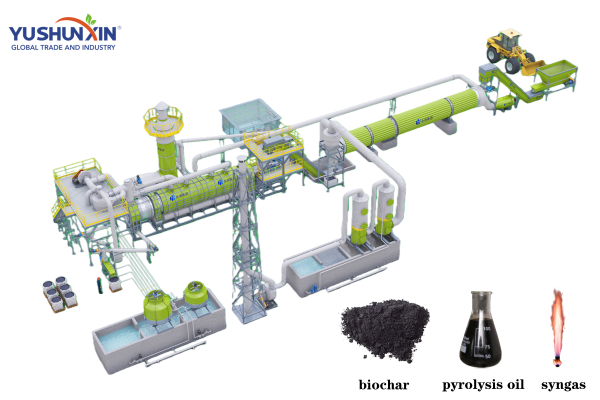

የባትሪ ባትሪዎች ፒሮሊቲስ

Utilizing high temperature to make the internal components of the battery undergo ፓይሮሊሲስ reaction, it takes one and a half hours and can improve the purity of black powder by 4-5%.

High-temperature cracking technology not only better retains the valuable metal elements inside the battery, እንደ Cobal, ኒኬል, ሊቲየም, ወዘተ, and improves the efficiency of battery recycling, but also greatly reduces the emission of hazardous substances that may be produced during the recycling process, and reduces the pollution of the environment.

የሊቲየም ባትሪነት መለያየት እንደገና ጥቅም ላይ የዋለ ቁሳቁሶች

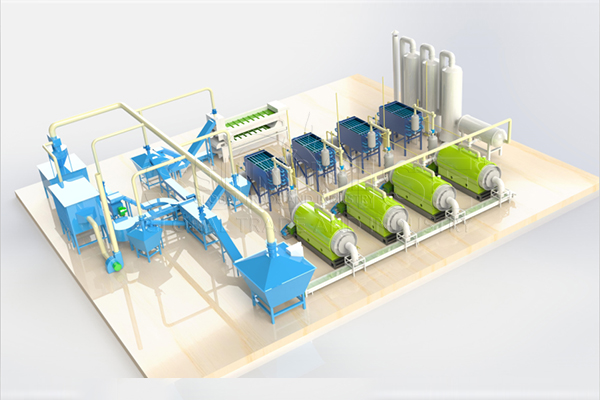

Advanced mechanical and physical separation techniques are used in lithium-battery recycling. Processes like Z-type separation, vibrating screening, drum screening, መግነጢሳዊ መለያየት, gravity separating, three-stage and four-stage crushing, along with linear and disc screening, isolate various materials. Metals, ፕላስቲኮች, and the black mass with lithium, Cobal, ኒኬል, and manganese are effectively separated for resource recovery.

At this point, after crushing, several types of substances will be decomposed, in addition to liquid electrolyte and black substances, there are also used to make the battery positive and negative aluminum and copper foil, plastic diaphragm and so on. This is the end of a complete lithium battery recycling process.

Check out the video below to see YSX machines in action at our factory. We cordially invite you to visit and witness our top-notch recycling equipment first-hand. Experience the precision and efficiency that sets our machinery apart!

በሊቲየም ባትሪዎች ውስጥ ምን የመጨረሻ ምርቶች እንደገና ጥቅም ላይ ሊውሉ ይችላሉ?

In lithium battery recycling, various valuable final products can be obtained. Aluminum shot is recycled from battery casings, useful in metalworking. የመዳብ ተኩስ, ከሽብተኞች ተመለሰ, ለኤሌክትሮኒክስ በጣም የተለመደ ነው. ሊቲየም ዱቄት, ቁልፍ አካል, ለአዳዲስ የባትሪ ምርት አስፈላጊ ነው. ግራፊክ ዱቄት, ከኤሌክትሮኖች, ባትሪዎች እና ቅባቶች ውስጥ ማመልከቻዎች አሉት.

የሊቲየም ባትሪ እንደገና ጥቅም ላይ የዋለው እንዴት ነው??

ከዚህ በታች በእፅዋት ዲዛይን ውስጥ ሊታሰብባቸው ከሚገቡት ቁልፍ ገጽታዎች መካከል አንዳንዶቹ ናቸው. እነዚህ ልዩ የዲዛይን እርምጃዎች ውጤታማውን ለማረጋገጥ ይረዳሉ, ደህንነቱ የተጠበቀ, እና ለአካባቢዎ የሎይየም-አዮን ባትሪ ሪቪንግ ሪሳይንግ ተቋም.

ከሂደት አንፃር ማመቻቸት

ምክንያታዊ የሆነ የመሬት ክፍል ክፍል የሥራ ቅልጥፍናን ማሻሻል ይችላል. ተክሉን ወደ መከፋፈል ይመከራል አምስት ዋና ዋና አካባቢዎች: ቦታ መቀበል (100-300 ㎡), የአደጋ ጊዜ አካባቢ (150-400 ㎡), የምደባ ቦታ (100-300 ㎡), ቦታን በማስኬድ (100-400 ㎡) እና የማጠራቀሚያ ቦታ (50-300 ㎡). እያንዳንዱ አካባቢ የመስቀል ብክለትን እና የስራ ማሰባሰብን ለመቀነስ ግልፅ ድንበሮች ሊኖሩት ይገባል.

A channel with a width of not less than 2 meters should be set to ensure smooth passage of forklifts and other transportation equipment, thereby reducing handling time.

የደህንነት ንድፍ እይታ

At least one fire extinguisher should be equipped for every 100 m2, and a fire sprinkler system should be installed in key areas. Regularly conduct safety drills once a quarter to ensure that workers are familiar with the operating procedures in emergency situations.

What are the Costs of a Lithium Battery Recycling Plant?

The cost to break the battery down lithium batteries is depend on the volume you want.

1. For a recycling factory with an hourly output of 300 - - 500 ኪግ

The price range is between $50,000 እና $100,000. The equipment involved includes ተከላካዮች, መከለያዎች, screening machines, and separation equipment, ወዘተ. The total floor area spans from 300 ለ 500 ㎡.

2. When it comes to a recycling factory having an hourly output of 500 - - 800 ኪግ

The price range is from $100,000 ለ $300,000. The total area lies between 500 እና 600 ㎡.

3. In the case of a recycling factory with an hourly output of 800 - - 1200 ኪግ

The price range is from $300,000 ለ $450,000. It’s a large automatic recycling prodution line. The total floor area is from 600 ለ 900 ㎡.

How About Our Customer Feedback of Lithium Battery Recycling Machines?

I’m not sure how to dispose the large amount of waste lithium batteries I had, thanks for YUSHUNXIN giving me good advice and proposal. Building a circular supply chain will help me maintain business stability into the future. Thanks!

I process around 300 kilograms of used car batteries and other lithium batteries every day. Since I started using YSX’s battery recycling production line equipment, it’s been amazing. I can efficiently extract and reuse those crucial battery materials. Seriously, I’m super grateful. You guys have really helped me out a ton.

እኛን ያግኙን